Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a world without the smooth, silent action of a door hinge, the gentle bounce of a car suspension, or the precise movement of a watch. These seemingly simple functions

Imagine a world without the smooth, silent action of a door hinge, the gentle bounce of a car suspension, or the precise movement of a watch. These seemingly simple functions are made possible by a ubiquitous yet often overlooked component: the flat spring. Flat springs, deceptively simple in appearance, are essential elements in countless mechanical systems, silently performing their duty with remarkable resilience and precision. This article delves into the fascinating world of flat springs, exploring their design, applications, and the essential role they play in modern engineering.

A flat spring is a flexible metal strip, often made of steel, that is designed to deflect under load and return to its original shape when the load is removed. Unlike their coiled counterparts, flat springs derive their strength and resilience from their shape, thickness, and material properties. Their flat geometry allows for a variety of configurations and functions, making them incredibly versatile components in engineering.

The key to understanding flat springs lies in their ability to store and release energy. When a force is applied to a flat spring, it bends or deflects, storing potential energy within its structure. As the force is removed, the spring's inherent elasticity pushes it back to its original shape, releasing the stored energy. This simple principle forms the foundation for a wide range of applications, from the tiny springs in a watch mechanism to the massive leaf springs in heavy-duty vehicles.

Flat springs come in various shapes and configurations, each tailored to specific applications. Here are some of the most common types:

Designing a flat spring for a specific application requires careful consideration of several factors, including:

The versatility of flat springs makes them indispensable components in a wide range of industries. Here are some prominent examples:

Flat springs, though often overlooked, are vital components that power countless mechanical systems. Their inherent resilience, versatility, and precision make them indispensable in industries ranging from automotive to aerospace and consumer goods. As we continue to rely on sophisticated mechanical systems, flat springs will remain essential elements in ensuring smooth, reliable, and efficient operation for countless years to come. They are truly the unsung heroes of engineering, silently working behind the scenes to make our world function.

The next time you encounter a smoothly operating door hinge, a comfortable car ride, or a precisely working clock, remember the small, unassuming flat spring quietly doing its job. These seemingly simple components play a vital role in our daily lives, a testament to the ingenuity and dedication of engineers who harness the power of elasticity to make our world a little bit smoother, a little bit more resilient, and a little bit more efficient.

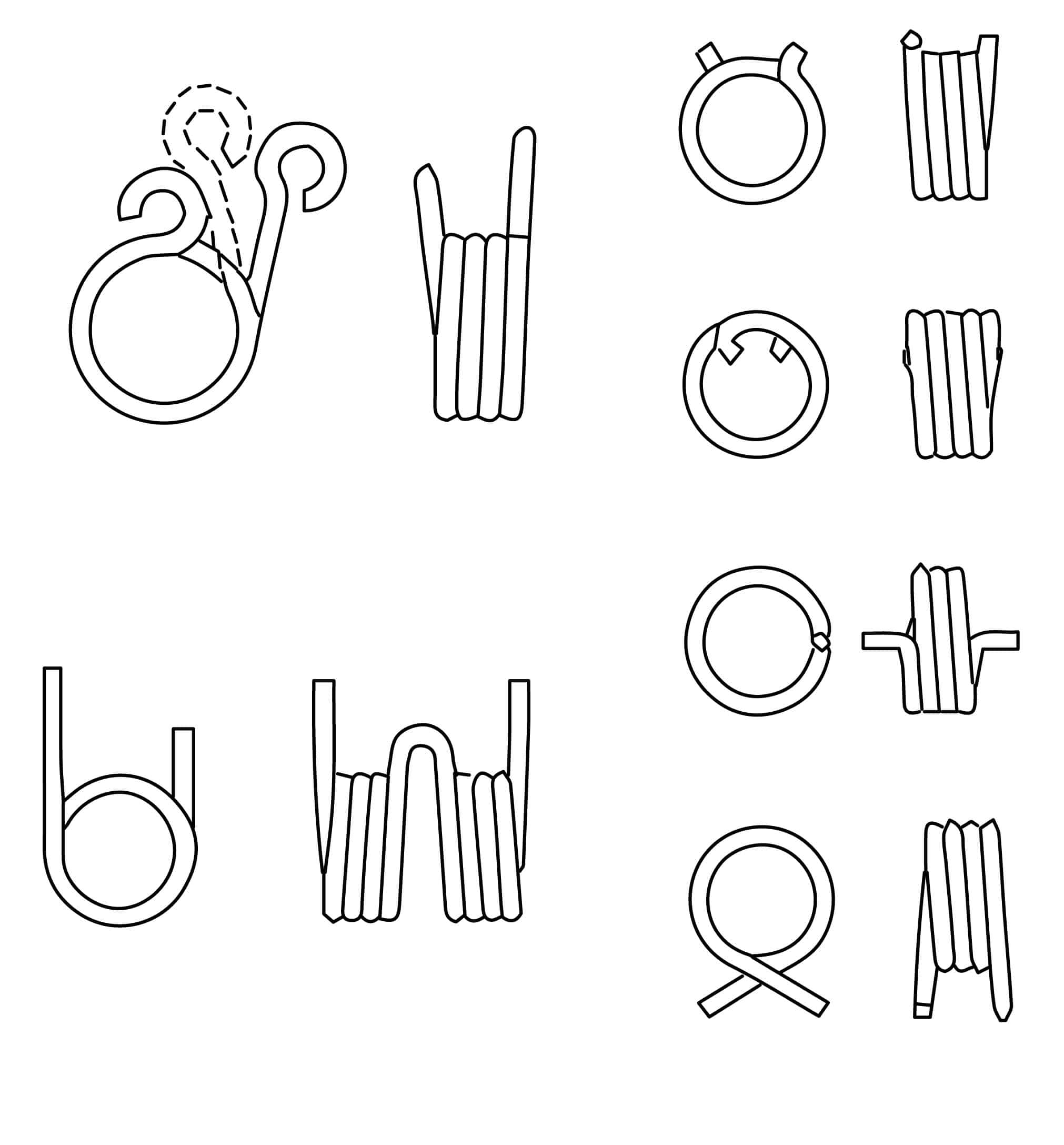

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.