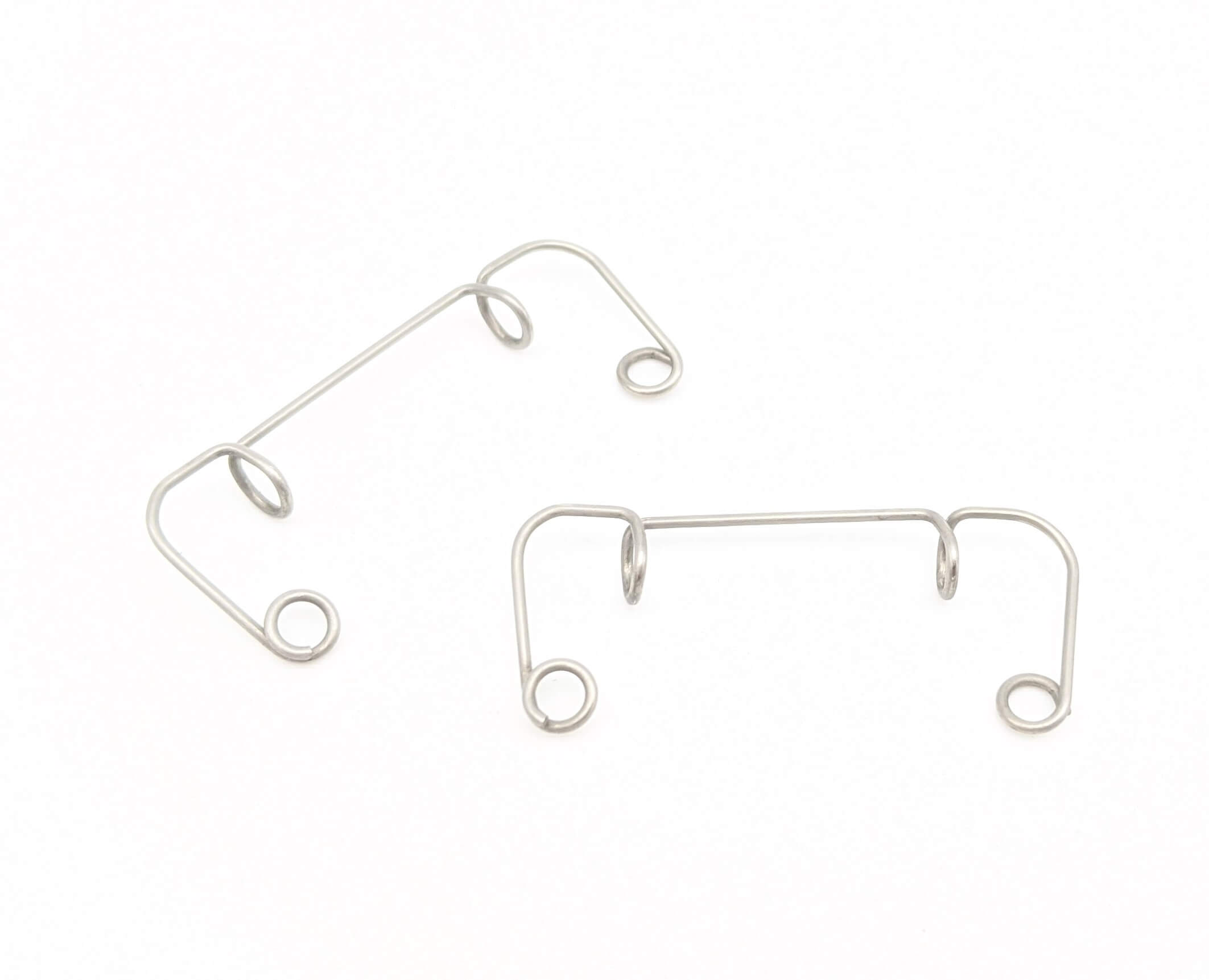

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Flat springs, also known as leaf springs, are a ubiquitous component in countless mechanical systems, from intricate watch mechanisms to the suspension systems of heavy-duty vehicles. These deceptively simple, yet

Flat springs, also known as leaf springs, are a ubiquitous component in countless mechanical systems, from intricate watch mechanisms to the suspension systems of heavy-duty vehicles. These deceptively simple, yet powerful, elements are formed from thin strips of spring steel, carefully designed to provide a reliable and predictable force when subjected to various types of loads. This article delves into the world of flat springs, exploring their construction, diverse applications, and the unique advantages that make them a favored choice for engineers and designers.

Flat springs are essentially flat strips of metal that are designed to bend or flex under load. They are usually made from high-quality spring steel, selected for its ability to withstand repeated stress cycles without permanent deformation. The design of a flat spring, including its length, width, thickness, and shape, directly influences its spring rate, which determines the force required to deflect the spring a certain distance. This makes flat springs incredibly versatile, allowing engineers to tailor them to specific application requirements.

Unlike their coiled counterparts, flat springs offer a unique advantage in their ability to handle both tension and compression loads. This versatility stems from the inherent strength of the flat shape, which allows for a more efficient distribution of stresses. Flat springs can be designed to withstand significant forces while maintaining their structural integrity. Their planar structure also makes them ideal for applications where space is limited, or where a compact and lightweight design is essential.

The creation of flat springs requires a meticulous process that balances precision with the need for strength and resilience. The most common method of flat spring manufacturing involves the use of specialized stamping machines. These machines are designed to cut, bend, and shape the spring steel with remarkable accuracy, ensuring that the finished product meets the exact specifications required for its application.

The process begins with high-quality spring steel in sheet or coil form. This steel is then fed into the stamping machine, where a series of dies and punches are used to cut the spring to its desired shape. This process is incredibly precise, with tolerances often measured in thousandths of an inch. After the initial shaping, the spring is then subjected to a heat treatment process, which is crucial for achieving the desired spring properties. Heat treatment involves carefully controlling the temperature and duration of the process to alter the metal's microstructure, enhancing its strength, hardness, and resistance to fatigue.

Flat springs are incredibly versatile and find their way into an astonishing array of applications. Their adaptability, combined with their ability to handle various loads and their compact design, makes them a staple component in countless industries. Let's explore some key areas where flat springs shine:

Within the intricate world of mechanical systems, flat springs are indispensable. They form the heart of many delicate mechanisms, offering precise control and reliable performance.

Flat springs have a significant role to play in electrical and electronic devices, providing the necessary spring force for switches, connectors, and other components. These applications often require high-quality materials and meticulous manufacturing processes to ensure longevity and reliability.

In the automotive and aerospace industries, flat springs are essential for creating durable and reliable components. They are commonly used in suspension systems, chassis frames, and other critical components, ensuring the smooth operation and safety of these vehicles.

Flat springs are not just found in sophisticated machinery; they are also widely used in everyday consumer products. From the spring-loaded clips on your binder to the hinges on your laptop, flat springs add convenience and functionality to our lives.

The popularity of flat springs is not accidental. They offer several advantages that make them a compelling choice for designers and engineers:

The ability to handle tension and compression loads makes flat springs incredibly versatile. They can be designed to meet a wide range of force requirements, making them suitable for a vast array of applications.

Flat springs can be designed to fit into tight spaces, making them ideal for applications where space is at a premium. This is especially advantageous in compact electronic devices or in intricate mechanical systems.

The high-quality materials and meticulous manufacturing processes used in flat spring production ensure that these components are highly durable, capable of enduring repeated stress cycles without failing. Their resilience makes them reliable for long-term use.

Flat springs can be engineered to provide precise forces and controlled movements, making them essential components in applications that require accurate and repeatable performance.

Flat springs, though seemingly simple, are the unsung heroes of countless engineering feats. Their ability to handle various loads, their space-saving design, and their enduring resilience make them indispensable components in a wide range of applications. From the tiniest electronic devices to the largest vehicles, flat springs silently contribute to the smooth operation and reliability of the world around us. As technology continues to advance, flat springs will continue to play a vital role in shaping the future of mechanical systems, ensuring that our world continues to function with precision and strength.

In conclusion, flat springs are a testament to the ingenuity of engineering. Their simple yet powerful design makes them an indispensable component in countless applications. As we continue to push the boundaries of technology, flat springs will remain an essential element, contributing to the creation of innovative and efficient systems that enhance our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.