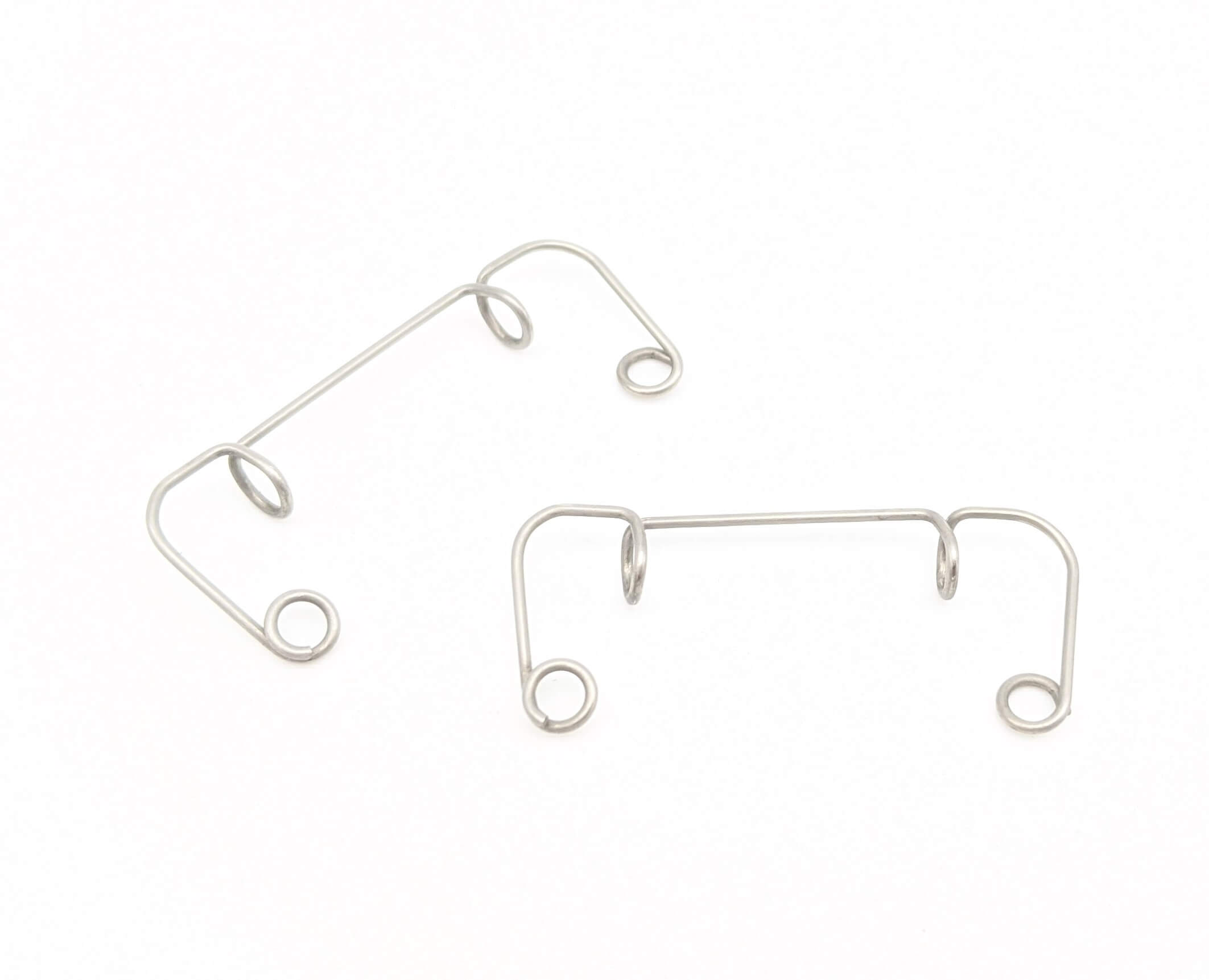

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Flat springs are a fundamental element in various mechanical and electrical systems. Their simple yet robust design offers a wide range of applications, providing flexibility, strength, and resilience to countless

Flat springs are a fundamental element in various mechanical and electrical systems. Their simple yet robust design offers a wide range of applications, providing flexibility, strength, and resilience to countless devices. This article will delve into the fascinating world of flat springs, exploring their characteristics, advantages, manufacturing processes, and diverse applications, showcasing their essential role in shaping modern engineering.

Flat springs, as the name suggests, are springs manufactured from flat spring steel. These springs offer a unique combination of flexibility and strength, allowing them to withstand significant forces while maintaining their shape and functionality. Unlike their coiled counterparts, flat springs exhibit a planar geometry, with the force applied perpendicular to their plane. This unique configuration results in a distinct set of properties that make them ideal for various applications.

The advantages of using flat springs are plentiful. Their ability to withstand high loads and stresses makes them suitable for demanding applications. Additionally, their versatility in design allows engineers to customize their shape, size, and material, ensuring they meet specific needs. Flat springs can be designed with varying thicknesses, widths, and lengths, providing diverse stiffness and deflection characteristics. This flexibility enables engineers to achieve the desired performance for specific applications.

Manufacturing flat springs typically involves several key steps, starting with the selection of high-quality spring steel. The choice of material depends on the specific application and the required properties. For example, stainless steel is often preferred for applications demanding corrosion resistance. Once the material is chosen, it undergoes a series of processes to shape and form the flat spring.

One common manufacturing method is stamping, where the flat spring steel is cut and shaped using a die. This process is efficient for high-volume production of flat springs with consistent dimensions. Another approach is bending, where the material is bent and formed into the desired shape. This process is often used for custom designs and smaller production runs. Regardless of the method used, the manufacturing process ensures that the flat spring possesses the necessary strength, flexibility, and dimensional accuracy for the desired application.

Flat springs are ubiquitous in various industries, their versatility making them a cornerstone in numerous applications. Some of the most common uses of flat springs include:

Flat springs play a crucial role in mechanical systems, providing essential support and stability. For example, they are commonly used in automotive suspension systems to absorb shocks and maintain ride comfort. Flat springs are also used in clutches, brakes, and gears, ensuring smooth and efficient operation. Their ability to store and release energy makes them ideal for creating spring-loaded mechanisms, such as locking systems and latching mechanisms.

The electrical industry also benefits from the unique characteristics of flat springs. They are widely used in switches, relays, and connectors, providing reliable contact points for electrical circuits. Their ability to withstand repetitive cycles of contact and separation ensures long-term reliability in demanding applications. Flat springs are also incorporated into electrical components such as circuit boards, acting as contact points for electronic devices.

The demanding environments of aerospace and defense applications require materials that are both strong and lightweight. Flat springs excel in these areas, offering a high strength-to-weight ratio. They are used in aircraft landing gears, aerospace actuators, and military equipment, providing essential functionality and resilience in extreme conditions. Flat springs are also employed in satellite components, ensuring stability and precision in space.

Flat springs find their way into countless consumer products, often unnoticed yet integral to their functionality. For example, they are commonly used in appliances such as washing machines and refrigerators, providing spring-loaded mechanisms for doors, drawers, and other moving parts. Flat springs are also essential components in toys, sporting equipment, and other consumer goods, enhancing their performance and durability.

When designing flat springs, several factors must be considered to ensure optimal performance and longevity. The most important considerations include:

Choosing the right material is crucial for the success of any flat spring application. Factors such as strength, stiffness, fatigue resistance, and corrosion resistance must be evaluated. Spring steel, stainless steel, and phosphor bronze are common choices, each offering unique properties.

The geometry of the flat spring significantly influences its characteristics. Factors such as thickness, width, length, and shape all contribute to the spring's stiffness, deflection, and overall performance. Careful consideration must be given to these factors during the design process.

Understanding how the load is applied to the flat spring is critical. The direction of the force, the magnitude of the load, and the frequency of the load cycle all influence the design and material selection. Ensuring that the flat spring is properly designed to handle the anticipated load is essential for its long-term reliability.

The manufacturing process significantly impacts the quality and performance of the flat spring. Selecting the appropriate method, such as stamping or bending, is essential to achieve the desired shape, accuracy, and surface finish. Quality control measures during manufacturing are also crucial to ensure the spring meets the specifications and provides optimal performance.

Flat springs are often subjected to repetitive cycles of loading and unloading. Understanding the potential for fatigue is crucial in ensuring the spring's longevity. Factors such as the frequency of the load cycle, the magnitude of the load, and the material properties all influence the spring's fatigue resistance. Careful design considerations and material selection are essential to minimize the risk of fatigue failure.

Flat springs are an integral part of modern engineering, offering a unique blend of flexibility, strength, and resilience. Their versatility in design, coupled with their widespread applications, makes them an indispensable component in countless systems. From automotive suspension systems to electrical components, flat springs contribute significantly to the functionality and performance of numerous devices. Their enduring power stems from their ability to store and release energy, provide support and stability, and withstand demanding conditions. As technology continues to evolve, flat springs will undoubtedly continue to play a vital role in shaping the future of engineering.

In conclusion, flat springs are a remarkable testament to the ingenuity of engineering. Their simple design and robust functionality have made them an essential component in a wide range of applications. Their ability to withstand significant loads, provide essential support, and contribute to diverse mechanisms highlights their enduring power in the world of design and innovation. As we continue to explore new possibilities in engineering, flat springs will continue to play a vital role, contributing to the creation of more efficient, reliable, and innovative solutions for the future.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.