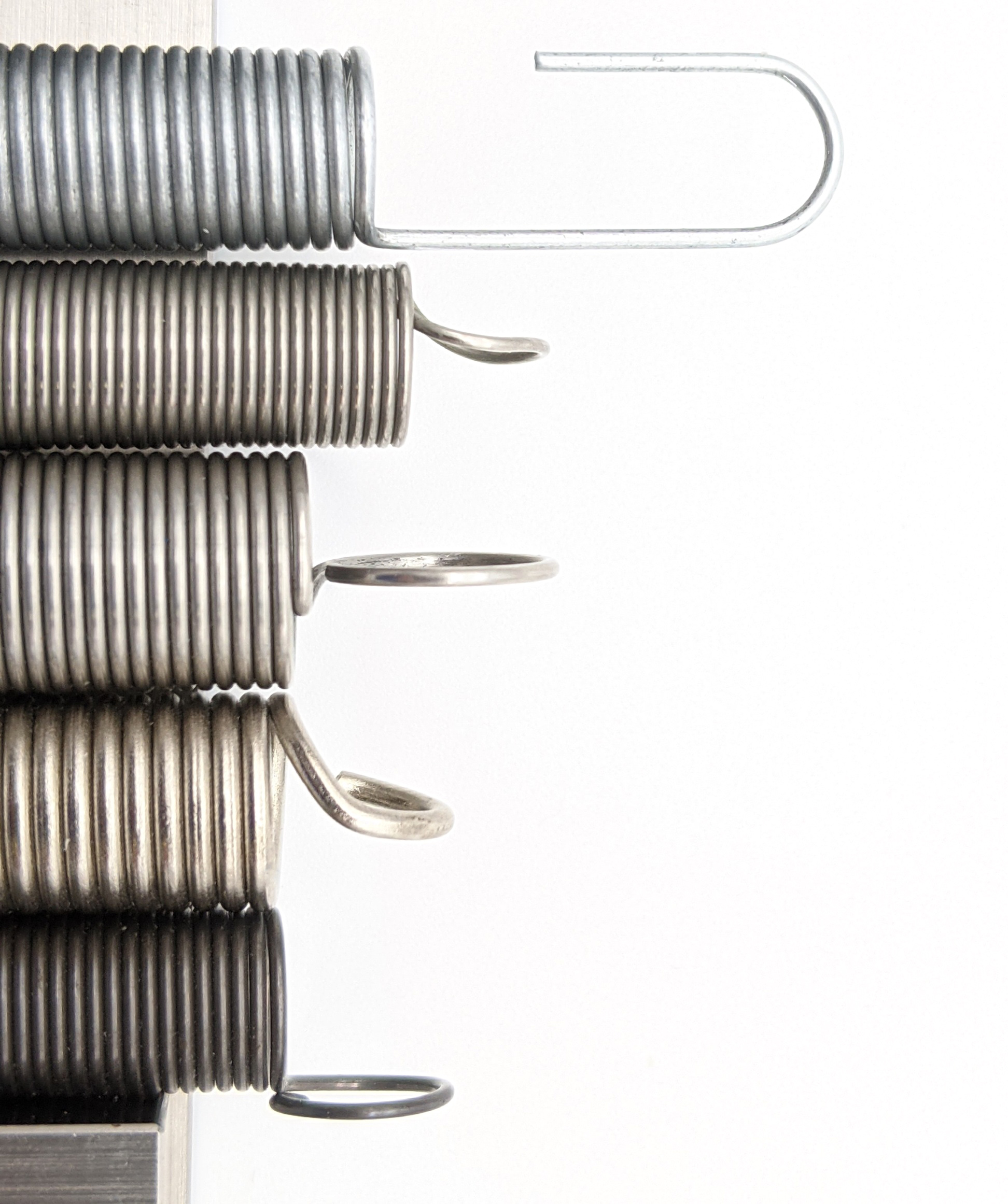

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Flat springs, also known as leaf springs, are a ubiquitous and indispensable component in mechanical systems, playing a crucial role in numerous applications. Their simple yet robust design allows them

Flat springs, also known as leaf springs, are a ubiquitous and indispensable component in mechanical systems, playing a crucial role in numerous applications. Their simple yet robust design allows them to provide a wide range of functionalities, from absorbing shocks and vibrations to providing support and restoring forces. These versatile components are found in a diverse array of industries, including automotive, aerospace, industrial machinery, and consumer goods, contributing significantly to the performance and reliability of countless devices.

Flat springs, or leaf springs, are essentially strips of elastic material, typically metal, that are designed to flex or bend under load. Their unique shape and material properties enable them to store and release mechanical energy, making them ideal for a variety of applications. The simplicity of their design allows for easy fabrication and integration into various systems, contributing to their widespread use.

Flat springs come in a variety of configurations, each tailored to specific applications and load requirements. Some common types include:

The versatility of flat springs makes them ideal for a wide range of applications across various industries:

Flat springs play a crucial role in automotive suspensions, providing support and absorbing shocks from bumps and uneven terrain. They are also used in clutches, brakes, and other components that require precise force control.

Flat springs are used in aircraft landing gear, control surfaces, and other components that require high strength and reliability. Their lightweight design and resistance to fatigue make them well-suited for aerospace applications.

Flat springs are essential in industrial machinery, providing support, tension, and force control in various applications. They are found in conveyor belts, presses, lathes, and other machinery where precise movement and reliable performance are critical.

Flat springs are used in a multitude of consumer products, including appliances, electronics, and toys. Their versatility and relatively low cost make them an ideal choice for these applications.

Flat springs offer a number of advantages that make them highly desirable in many applications:

Designing flat springs involves a number of considerations to ensure optimal performance and reliability:

Flat springs are a fundamental component in countless mechanical systems, contributing to their performance, reliability, and functionality. Their versatility, durability, and cost-effectiveness make them a highly desirable solution for a wide range of applications. Understanding the design considerations and advantages of flat springs is crucial for engineers and designers seeking to optimize their mechanical systems and ensure their long-term success.

In conclusion, flat springs are an indispensable component in a multitude of mechanical systems, offering a compelling combination of strength, durability, and versatility. Their ability to store and release mechanical energy, coupled with their cost-effectiveness, makes them a valuable asset in various industries. As we continue to explore new materials and manufacturing processes, flat springs will undoubtedly continue to play a vital role in shaping the future of mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.