Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Flat springs, also known as leaf springs, are a ubiquitous component in various mechanical designs, from everyday objects to complex machinery. Their unique shape, combined with the inherent properties of

Flat springs, also known as leaf springs, are a ubiquitous component in various mechanical designs, from everyday objects to complex machinery. Their unique shape, combined with the inherent properties of spring steel, allows them to withstand significant forces and deform elastically, returning to their original shape after the force is removed. Flat springs offer a remarkable combination of strength, flexibility, and resilience, making them an indispensable element in countless applications.

Imagine a thin, flat strip of spring steel. This seemingly simple piece of material holds within it the potential for incredible strength and versatility. Flat springs, also known as leaf springs, are crafted from this material and possess a remarkable ability to bend, flex, and return to their original shape repeatedly. This unique characteristic makes them an essential component in a wide range of applications, from simple everyday objects to complex machinery.

Flat springs offer several key advantages that make them attractive for designers and engineers:

Flat springs come in various shapes and sizes, each tailored for specific applications:

Flat springs are indispensable components in a wide range of industries and applications:

Flat springs are manufactured through a variety of processes, with the specific method depending on the desired shape, size, and properties of the spring. Common methods include:

Designing a flat spring requires a thorough understanding of the forces, loads, and deflections involved. Engineers use various formulas and software to calculate the optimal dimensions, material properties, and design configurations for specific applications. Some key considerations in flat spring design include:

Flat springs are a testament to the ingenuity and versatility of engineering. Their simplicity of design, combined with their exceptional properties, makes them a vital component in countless applications. Whether it's providing a smooth ride in a car, controlling the movement of industrial machinery, or ensuring the reliable operation of consumer products, flat springs continue to play a crucial role in our modern world.

The world of flat springs is rich with possibilities, offering designers and engineers a wealth of options for creating innovative and functional solutions. As technology advances, the applications of flat springs will likely expand further, highlighting their enduring importance in the realm of mechanical design.

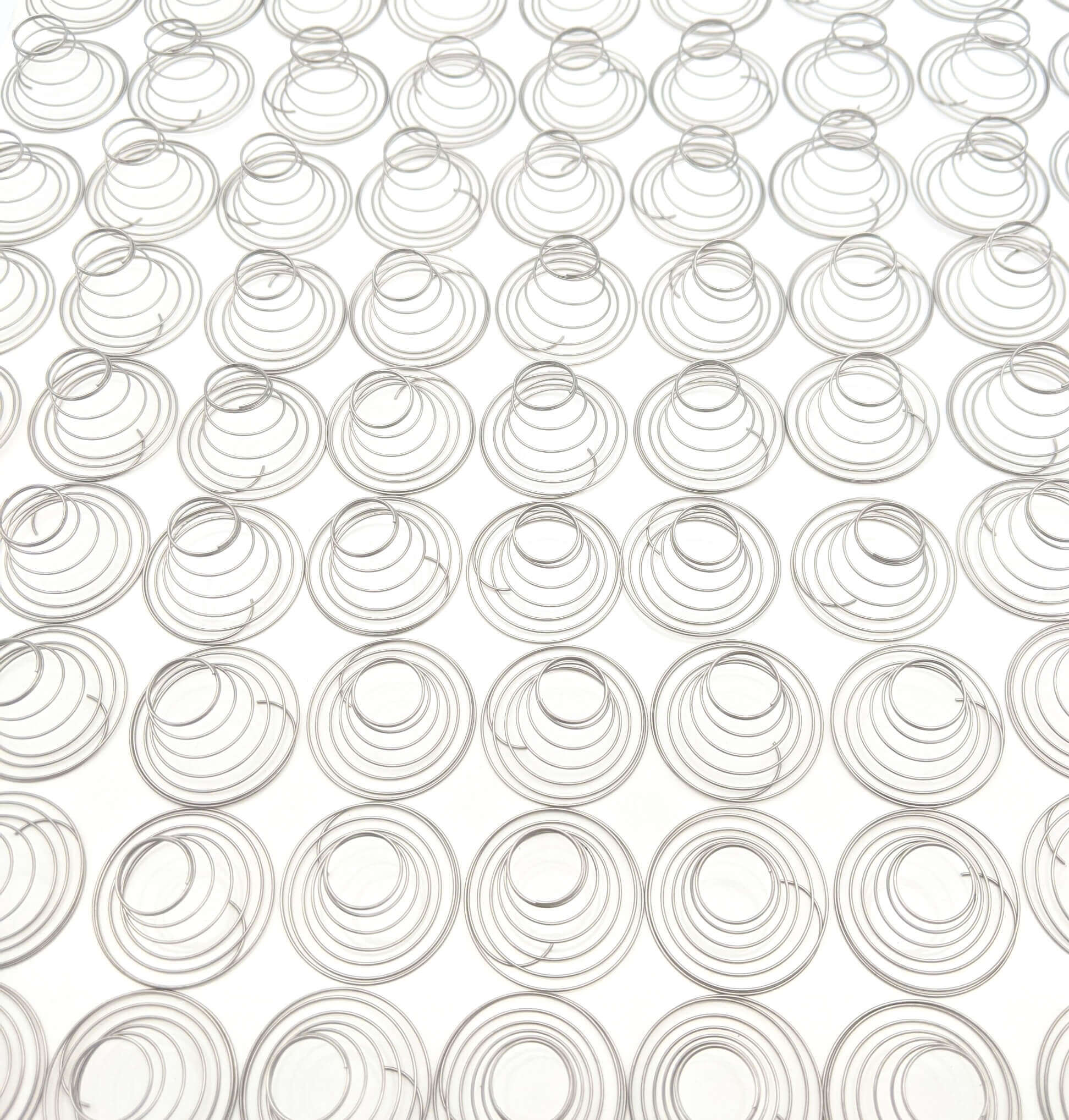

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.