Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Double torsion springs, often overlooked in the vast world of spring mechanics, are remarkable components with a unique twisting design. These springs, also known as helical torsion springs, are essential

Double torsion springs, often overlooked in the vast world of spring mechanics, are remarkable components with a unique twisting design. These springs, also known as helical torsion springs, are essential for a variety of applications, from controlling the motion of doors and windows to providing the spring force in a variety of machinery. Their versatility stems from their ability to store and release energy through twisting, offering a powerful and reliable solution for countless engineering challenges. This article delves into the fascinating world of double torsion springs, exploring their construction, advantages, applications, and considerations for effective use.

Imagine a spring that doesn't compress or extend but rather twists and untwists to generate force. That's the essence of a double torsion spring. Unlike conventional compression or extension springs, these springs are designed to resist twisting forces, storing energy in the process. The twisting action is a result of applying torque to the spring, causing it to wind up tighter or unwind. This winding and unwinding motion generates a force that can be harnessed for various purposes.

The construction of a double torsion spring is relatively simple, yet elegant. It typically consists of a single length of wire coiled into a helical shape. This coil, when subjected to a twisting force, will resist the rotation and store the applied energy. The amount of force the spring generates is directly proportional to the amount of twisting it undergoes. This relationship is governed by the spring's rate, a crucial factor in determining the force output.

Double torsion springs offer several advantages that make them ideal for a wide range of applications. Some of the key benefits include:

High Energy Storage: Double torsion springs are highly efficient at storing energy, allowing them to deliver substantial force when released. This characteristic makes them perfect for applications requiring high power output, such as door closers, window mechanisms, and certain types of machinery.

Compact Design: The helical shape of double torsion springs allows for a compact design, ideal for situations where space is limited. They can be easily integrated into various systems, making them a versatile choice for a multitude of designs.

Precise Control: Double torsion springs are known for their consistent performance and precise control over motion. This accuracy makes them suitable for applications where precise movement is crucial, such as in automotive components, medical devices, and aerospace applications.

Durability: Double torsion springs, especially those made from high-quality spring steel, are incredibly durable and resistant to wear and tear. They can withstand repeated twisting cycles without significant degradation, ensuring a long service life.

The versatility of double torsion springs makes them valuable components in various industries. Some notable applications include:

Door and Window Mechanisms: Double torsion springs are commonly used in door closers and window mechanisms. They provide the necessary force to close doors and windows smoothly and reliably, ensuring safety and energy efficiency.

Automotive Components: These springs are frequently employed in automotive applications, such as controlling the movement of seatbacks, hood hinges, and other components. They offer the required spring force for smooth and reliable operation.

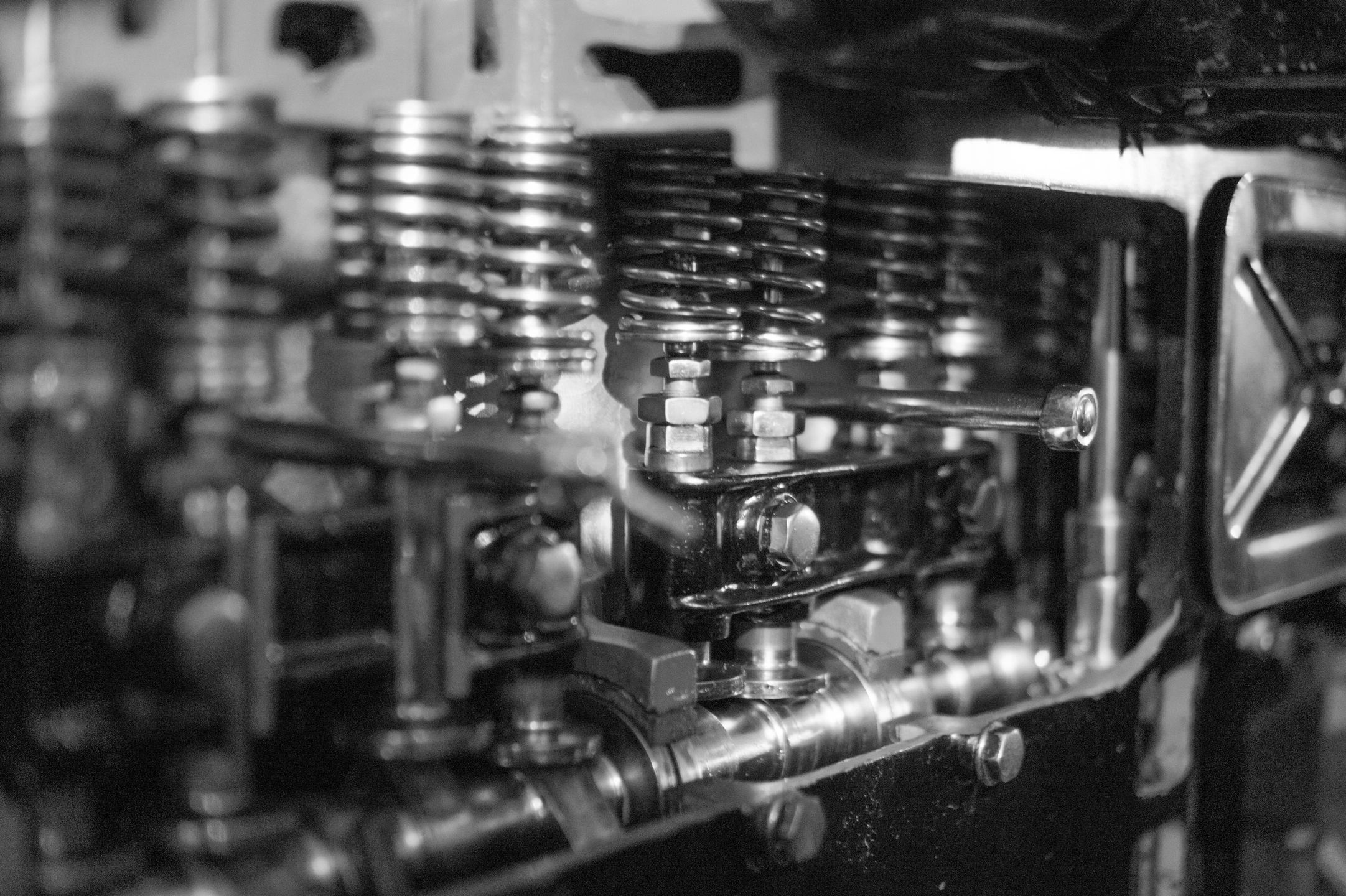

Machinery and Equipment: Double torsion springs play a vital role in a variety of machines and equipment, providing the necessary force for various functions. They are commonly found in power tools, industrial machinery, and various mechanical systems.

Medical Devices: Due to their precise control and durability, double torsion springs are used in medical devices, including surgical instruments, medical implants, and diagnostic equipment.

Aerospace Applications: The lightweight and robust nature of double torsion springs makes them suitable for aerospace applications, where weight is a critical factor. They are found in aircraft control systems, landing gear, and other aerospace components.

Selecting the correct double torsion spring for a specific application is crucial for optimal performance and reliability. Several factors should be considered, including:

Spring Rate: The spring rate, defined as the change in torque per unit twist, is a crucial factor in determining the force output of the spring. It needs to be carefully selected based on the required force and application.

Wire Diameter: The diameter of the wire used to make the spring significantly affects its strength and stiffness. Thicker wire yields a stronger and stiffer spring, while thinner wire offers greater flexibility.

Coil Diameter: The diameter of the spring coil influences its flexibility and energy storage capacity. Smaller coil diameters generally result in a more flexible and less energy-intensive spring.

Material: The material of the spring significantly affects its durability, resistance to corrosion, and overall performance. High-quality spring steel is commonly used for its excellent strength and resilience.

Operating Environment: The operating environment, including temperature and humidity, can influence the spring's performance. Choosing a spring suitable for the specific environment is essential for long-term reliability.

Double torsion springs are invaluable components in a wide range of applications, offering a unique solution for controlling motion and storing energy. Their versatility, compact design, and precise control make them an excellent choice for various engineering challenges. Understanding the fundamental principles of double torsion springs, their advantages, applications, and considerations for selection is crucial for achieving optimal results in diverse engineering projects.

As you delve deeper into the world of spring mechanics, you'll find double torsion springs to be fascinating and valuable components. Their ability to store and release energy through twisting, coupled with their versatility and durability, makes them essential in a variety of industries. Whether you're designing door closers, automotive components, or intricate machinery, double torsion springs offer a unique and effective solution, adding a touch of elegance and power to your engineering designs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.