Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Double torsion springs, often referred to as "double-ended torsion springs," are specialized components in mechanical systems that deliver a unique combination of power and precision. These springs are essentially two

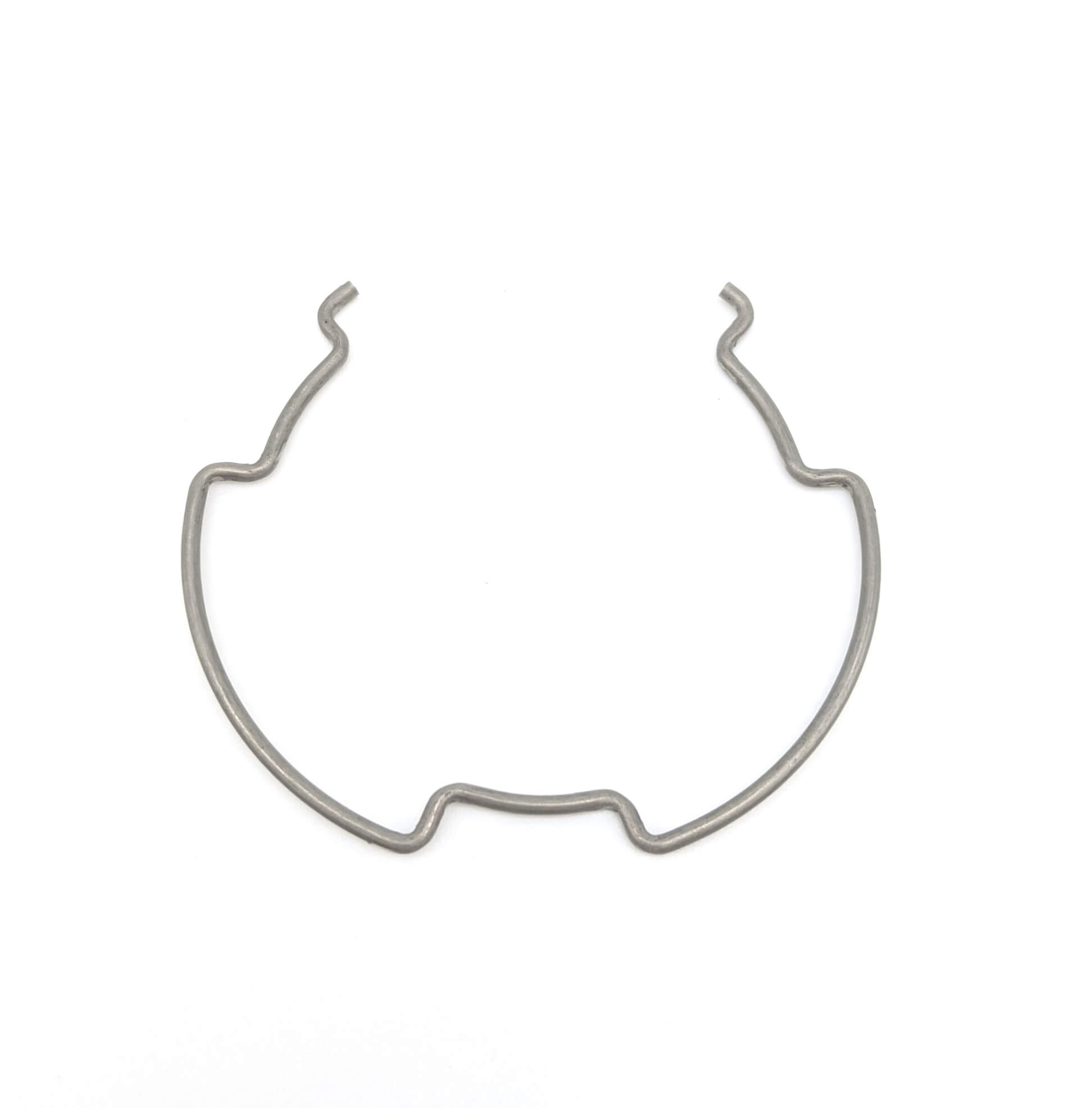

Double torsion springs, often referred to as "double-ended torsion springs," are specialized components in mechanical systems that deliver a unique combination of power and precision. These springs are essentially two individual torsion springs joined together, creating a system that exerts a rotational force in two opposing directions. This unique design has a wide range of applications, from delicate mechanisms in watches to the robust systems found in heavy machinery. We'll delve into the intriguing world of double torsion springs, exploring their characteristics, design principles, and diverse applications.

Imagine a spring that not only twists but also exerts force in both directions—that's the essence of a double torsion spring. Unlike their single-ended counterparts, these springs are crafted from a continuous length of wire that is carefully coiled twice, creating two separate spring sections. This dual-coiling design allows the spring to exert a rotational force in two distinct directions, effectively doubling the potential torque output.

The unique design and capabilities of double torsion springs make them incredibly versatile components. They are found in a wide range of applications, where their ability to exert controlled rotational force is crucial. Let's explore some key applications:

The automotive sector is a significant user of double torsion springs. They can be found in:

The demands of heavy-duty machinery often call for robust components, and double torsion springs deliver. They are employed in:

Despite their power, double torsion springs are also employed in delicate electronic devices, thanks to their precision and reliability. They are used in:

The design of double torsion springs requires a careful consideration of factors like wire diameter, coil diameter, number of coils, and material properties. Here are some key considerations:

Here are some key advantages of double torsion springs:

While double torsion springs offer numerous benefits, there are some challenges and considerations:

Double torsion springs are impressive components that pack a powerful punch in a compact package. Their ability to deliver controlled rotational force in both directions makes them essential for diverse applications, from the miniature mechanisms of watches to the robust systems of heavy-duty machinery. As we continue to push the boundaries of mechanical engineering, double torsion springs will undoubtedly remain vital for driving innovation and creating powerful, reliable solutions for various industries.

From the intricate workings of timepieces to the heavy-duty demands of industrial machinery, double torsion springs are a testament to the ingenuity of mechanical design. Their unique design allows for powerful and precise rotational force, making them a versatile solution for countless applications. As technology advances, we can anticipate even more innovative uses for these remarkable springs, further solidifying their place as essential components in the world of mechanics.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.