Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

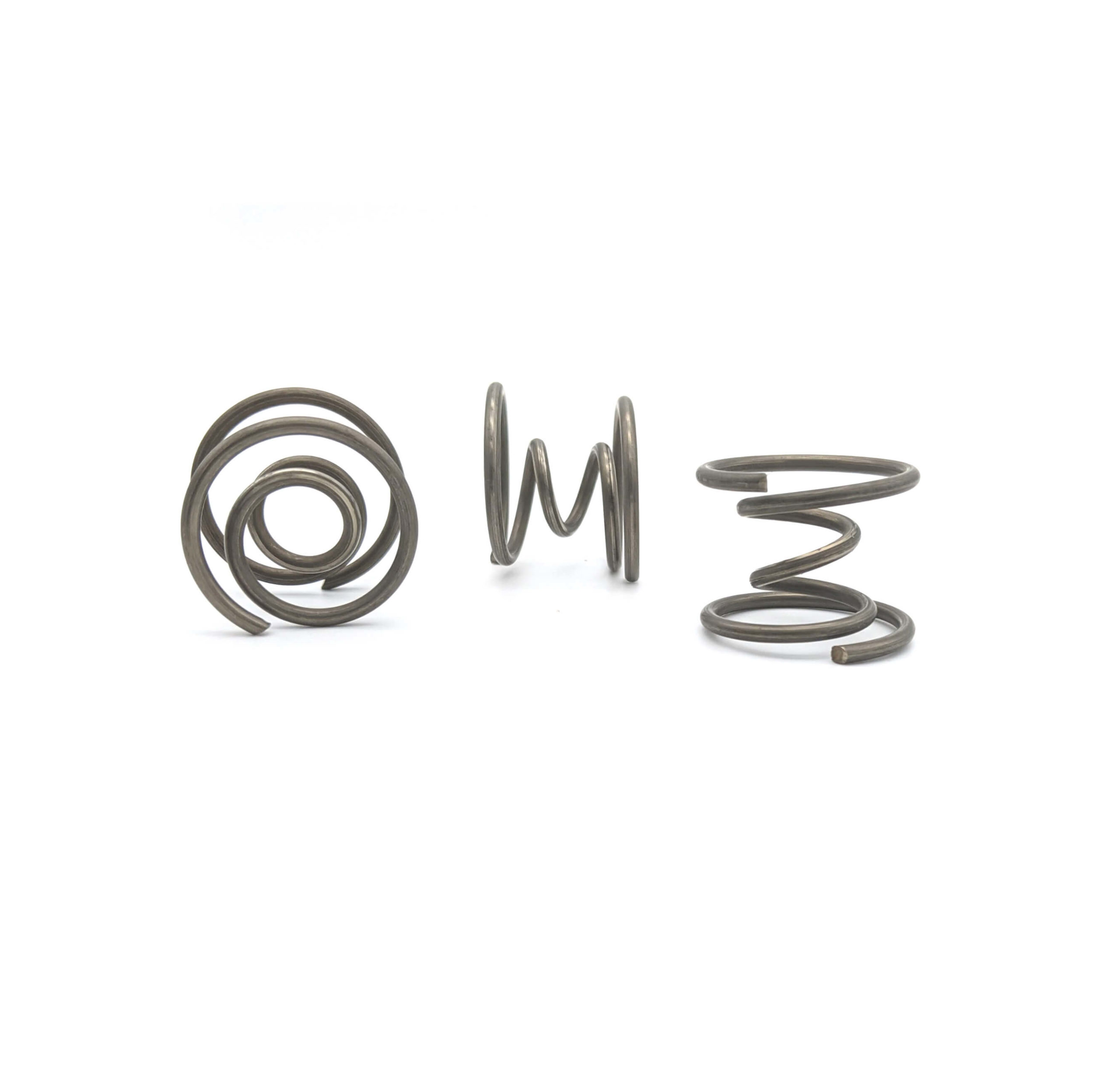

Wave springs, also known as wave washers, are a unique and ingenious type of spring that offer exceptional advantages over traditional coil springs. Unlike the familiar helical coil springs, wave

Wave springs, also known as wave washers, are a unique and ingenious type of spring that offer exceptional advantages over traditional coil springs. Unlike the familiar helical coil springs, wave springs utilize a series of precisely engineered waves to generate spring force, providing unmatched performance in various applications. Custom wave springs, in particular, are designed and manufactured to meet specific requirements, ensuring optimal functionality and reliability. This article explores the world of custom wave springs, delving into their unique characteristics, benefits, and the critical considerations involved in their selection and application.

Imagine a spring that's compact, robust, and can handle substantial loads while remaining remarkably efficient. This is the reality of wave springs, a testament to the ingenuity of spring technology. These springs, often referred to as wave washers, differ significantly from their coil spring counterparts in both design and function. Instead of relying on helical coils, wave springs consist of a series of precisely engineered waves, each meticulously formed to provide a unique spring characteristic.

One of the most captivating features of wave springs is their remarkable ability to achieve high spring rates within a compact footprint. This inherent characteristic makes them ideal for applications where space is limited, and high spring forces are essential. Moreover, their design allows for consistent and predictable performance, even under extreme loads and temperature fluctuations.

While standard wave springs offer a compelling solution for many applications, custom wave springs truly shine when specialized requirements demand tailored solutions. These springs are engineered to meet specific parameters, providing optimized performance for unique situations. Let's explore some of the key advantages that custom wave springs offer:

1. Tailored Performance: Custom wave springs are designed to deliver precise spring rates, deflections, and load capacities. This ensures optimal functionality in specific applications, whether it's providing a precise force for a delicate mechanism or handling heavy-duty loads in a demanding environment.

2. Compact Footprint: When space is a premium, custom wave springs offer a significant advantage. Their unique wave design allows for exceptional spring force generation within a remarkably compact footprint, making them ideal for applications where space is limited. Imagine fitting a high-performance spring into a tight spot, precisely what custom wave springs achieve.

3. Enhanced Durability: The robust design of custom wave springs translates into exceptional durability and resistance to wear and tear. They can handle significant cyclic loads and maintain their integrity over extended periods, ensuring reliable performance in even the most demanding environments. Imagine a spring that can withstand extreme conditions and continue to perform without compromise. This is the hallmark of custom wave springs.

4. Precise Control: Custom wave springs offer unparalleled control over spring characteristics. Engineers can fine-tune the wave geometry, material selection, and heat treatment to achieve precise spring rates and deflections, ensuring that the spring meets the exact demands of the application.

The versatility of custom wave springs extends to a wide range of industries and applications. Their unique characteristics make them invaluable in various engineering solutions, from aerospace and automotive to medical devices and consumer products. Some notable applications include:

1. Aerospace: Custom wave springs are employed in critical components of aircraft, satellites, and rockets. Their ability to handle extreme temperatures, vibrations, and loads ensures the reliability and safety of these high-performance systems.

2. Automotive: In automotive applications, custom wave springs are used in suspension systems, clutches, and transmissions. They provide precise control and durability, enhancing the performance and safety of vehicles.

3. Medical Devices: The biocompatibility and precision of custom wave springs make them suitable for medical devices such as surgical instruments, implants, and prosthetics. Their ability to provide controlled forces and movements ensures patient safety and effective treatments.

4. Consumer Products: Custom wave springs find their way into a wide range of consumer products, from electronic devices and toys to appliances and sporting goods. They provide smooth operation, durability, and reliable performance, enhancing the user experience.

Choosing the optimal custom wave spring for a specific application involves careful consideration of several factors:

1. Spring Rate: The spring rate, often expressed in pounds per inch or newtons per meter, defines the force required to compress or extend the spring by a given distance. Selecting the appropriate spring rate is crucial for ensuring the correct functionality and performance of the application.

2. Deflection: The deflection of a spring refers to the amount it compresses or extends under a specific load. Defining the desired deflection is essential for determining the proper spring size and material.

3. Load Capacity: The load capacity of a spring represents the maximum force it can withstand without permanent deformation or failure. Selecting a spring with sufficient load capacity is vital for ensuring safety and longevity.

4. Material: The choice of material for a custom wave spring is critical for performance and durability. Various materials are available, each offering unique properties, such as corrosion resistance, temperature tolerance, and fatigue strength.

5. Manufacturing Process: The manufacturing process for custom wave springs plays a significant role in achieving the desired specifications and quality. Precision manufacturing techniques, such as CNC machining and wire forming, ensure high accuracy and repeatability.

Custom wave springs represent a remarkable innovation in spring technology, offering exceptional performance, durability, and versatility. Their tailored design allows for precise control of spring characteristics, making them ideal for demanding applications across various industries. By carefully considering the factors discussed above, engineers can select the optimal custom wave spring to ensure the success of their projects. As technology continues to advance, we can expect to see even more innovative applications of custom wave springs, further pushing the boundaries of engineering and design.

In conclusion, custom wave springs are a testament to the power of precision engineering and design. Their unique characteristics and versatility have revolutionized the way engineers approach spring solutions. As technology advances and new applications emerge, custom wave springs will continue to play a vital role in shaping the future of various industries. They embody a commitment to achieving optimal performance, reliability, and innovation, solidifying their position as a cornerstone of modern engineering design.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.