Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

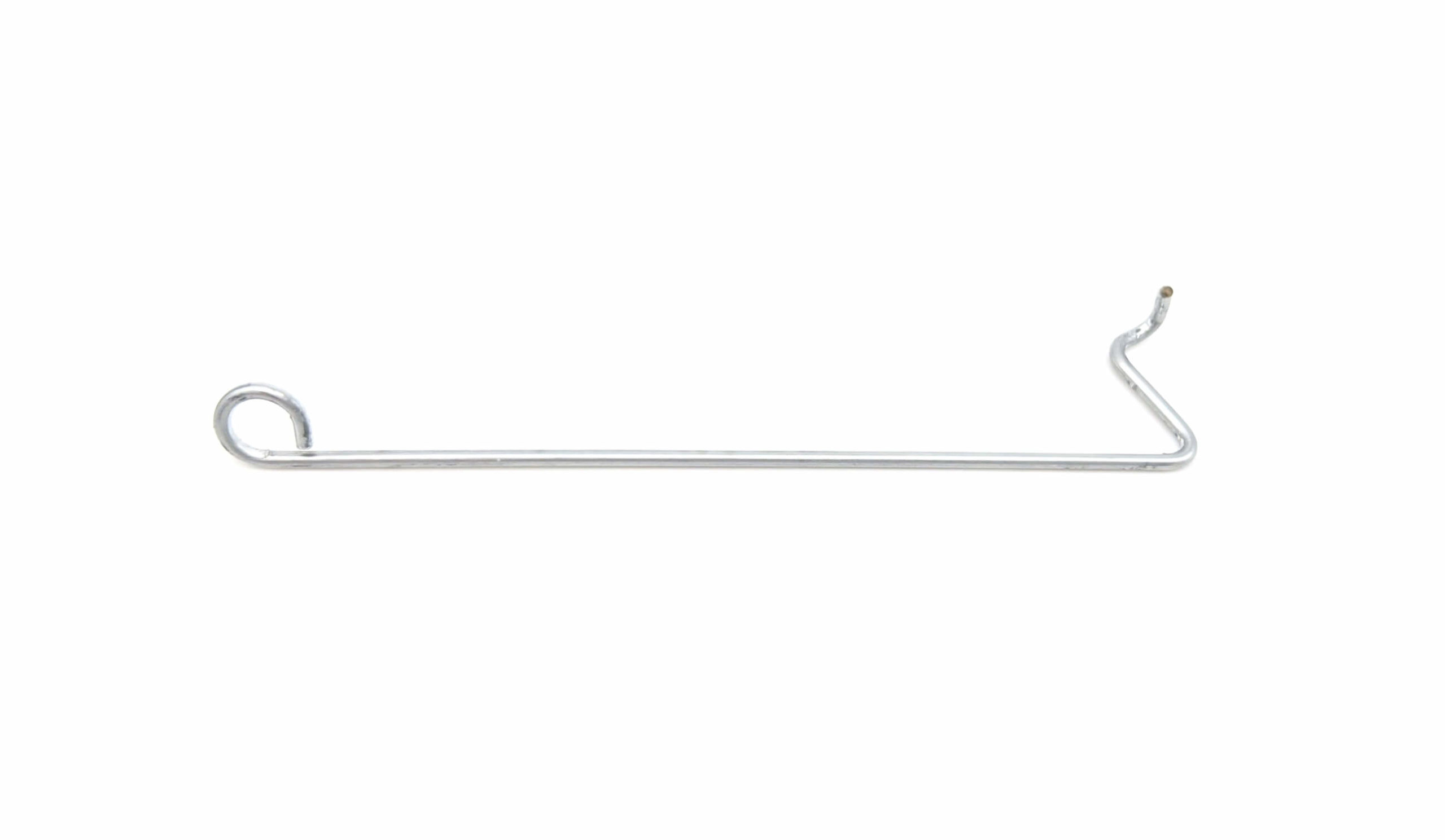

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Custom wave springs, also known as wave washers or Belleville springs, are a unique type of spring that offers exceptional load-bearing capacity, high fatigue resistance, and a compact design. They

Custom wave springs, also known as wave washers or Belleville springs, are a unique type of spring that offers exceptional load-bearing capacity, high fatigue resistance, and a compact design. They are distinct from traditional helical springs, possessing a wave-like configuration that provides a progressive spring rate. This feature allows them to deliver consistent force over a larger deflection range, making them ideal for various applications where reliability and precision are paramount. From high-pressure clamping in automotive systems to precise tension control in medical devices, custom wave springs have proven to be indispensable components in numerous industries. This comprehensive guide will delve into the intricacies of wave spring design, exploring their advantages, applications, and the customization possibilities that make them so versatile.

Custom wave springs are typically made from high-quality spring steel or other resilient materials. Their unique design involves a series of concentric waves or conical shapes stacked together. This configuration allows for a progressive spring rate, meaning the force required to compress the spring increases as it is compressed further. Unlike helical springs, which offer a constant spring rate, wave springs provide a nonlinear force response that can be tailored to specific application requirements. This characteristic is highly beneficial for applications requiring precise force control and reliable performance under varying load conditions.

The specific properties of a custom wave spring are determined by factors such as the material type, the number of waves, the diameter, and the thickness of the spring. These parameters can be meticulously controlled during the design process to achieve the desired spring rate, deflection range, and load capacity. The flexibility in customization allows for a wide range of applications, ranging from high-pressure clamping in aerospace components to delicate tension control in medical devices.

Custom wave springs offer several advantages over traditional helical springs, making them a highly sought-after solution in various engineering and design applications. Some of the key benefits include:

1. High Load Capacity: Custom wave springs are renowned for their exceptional load-bearing capacity, often exceeding that of helical springs of comparable size. This feature is particularly advantageous in applications where compact components are required to handle significant forces.

2. Progressive Spring Rate: The progressive spring rate inherent in wave spring designs provides a more consistent force distribution over a larger deflection range. This characteristic is crucial for applications requiring controlled force application and prevents sudden load spikes that can lead to component failure.

3. High Fatigue Resistance: Custom wave springs are known for their exceptional fatigue resistance. They can withstand repeated cycles of compression and release without experiencing premature wear or failure. This durability is essential in applications subject to dynamic loads and demanding operating conditions.

4. Compact Design: Compared to helical springs, custom wave springs can achieve the same load capacity in a smaller footprint. This space-saving characteristic is highly desirable in compact designs where limited space is available.

5. Precise Customization: The ability to customize the design parameters of wave springs allows engineers to tailor them to specific application requirements. From the spring rate and deflection range to the material type and surface finish, wave springs can be meticulously engineered for optimal performance and reliability.

The versatility and unique characteristics of custom wave springs make them suitable for a wide range of applications across various industries. Some of the most common applications include:

1. Automotive: Custom wave springs find widespread use in automotive applications, such as:

* **Clutch Systems:** Wave springs provide consistent force for clutch actuation, ensuring smooth gear changes and optimal performance.

* **Suspension Systems:** In suspension systems, wave springs offer a progressive spring rate that provides a comfortable ride and improved handling.

* **Braking Systems:** Wave springs are used in braking systems to provide clamping force, ensuring consistent and reliable brake operation.

2. Aerospace: The lightweight and high load capacity of custom wave springs make them ideal for aerospace applications, such as:

* **Landing Gear:** Wave springs are used in landing gear systems to absorb shock during landings and takeoffs, ensuring aircraft safety and structural integrity.

* **Rocket Engines:** In rocket engines, wave springs provide a reliable force for clamping and sealing components, ensuring optimal performance and preventing leaks.

3. Medical Devices: The precision and reliability of custom wave springs make them indispensable in medical devices, including:

* **Medical Implants:** Wave springs can be incorporated into medical implants, such as prosthetic joints, to provide controlled movement and support.

* **Surgical Instruments:** The delicate force control offered by wave springs is essential in surgical instruments, allowing for precise manipulation and minimal tissue damage.

4. Industrial Machinery: Custom wave springs are extensively used in industrial machinery applications, such as:

* **Presses and Dies:** Wave springs provide consistent force for clamping and releasing dies in manufacturing processes, ensuring accurate product formation.

* **Conveyor Systems:** Wave springs are used in conveyor systems to provide tension and maintain consistent product movement.

5. Electronics and Electrical Equipment: The compact design and reliable performance of wave springs make them suitable for various electronic and electrical applications, including:

* **Connectors and Switches:** Wave springs provide a secure and consistent connection in connectors and switches, ensuring reliable electrical contacts.

* **Circuit Boards:** Wave springs can be used to secure components on circuit boards, preventing vibration-induced failures.

Selecting the right custom wave spring for a particular application involves careful consideration of several factors, including:

1. Load Requirements: Determine the maximum load the spring needs to handle, considering static and dynamic forces.

2. Deflection Range: Define the desired deflection range, ensuring the spring can operate within the necessary limits.

3. Spring Rate: Specify the required spring rate to achieve the desired force response and load distribution.

4. Material Selection: Choose a suitable material, such as spring steel, stainless steel, or other alloys, based on the application's operating environment and required corrosion resistance.

5. Dimensions and Tolerance: Consider the available space for the spring and establish the required tolerance levels for accurate installation and performance.

Custom wave springs offer unparalleled flexibility, allowing engineers to tailor them to meet specific application demands. This ability to customize is crucial for achieving optimal performance and reliability in various engineering challenges. Key customization options include:

1. Material Selection: A variety of materials can be used to manufacture custom wave springs, allowing for the selection of the material best suited for the application's environmental conditions and load requirements.

2. Wave Shape and Configuration: The shape and configuration of the waves can be customized to fine-tune the spring rate and deflection range, ensuring precise force control and optimal performance.

3. Dimensions: The overall dimensions of the spring, including the diameter, thickness, and number of waves, can be adjusted to fit specific space constraints and achieve the desired load capacity.

4. Surface Finish: Custom wave springs can be provided with various surface finishes, including plating and coatings, to enhance corrosion resistance, lubricity, or wear resistance.

5. Tolerances: Tight tolerances can be specified during the manufacturing process to ensure the spring's precise dimensions and consistent performance.

Custom wave springs represent a sophisticated and versatile spring solution that offers significant advantages over traditional helical springs. Their high load capacity, progressive spring rate, compact design, and precise customization capabilities make them ideal for a wide range of applications where reliability and performance are paramount. Whether it's automotive systems, aerospace components, medical devices, or industrial machinery, custom wave springs offer a reliable and efficient way to handle demanding load conditions and achieve precise force control. By understanding the design, benefits, applications, and customization possibilities of custom wave springs, engineers can leverage their unique characteristics to optimize their designs and create innovative solutions across various industries.

The exceptional qualities of custom wave springs position them as a valuable asset in modern engineering. Their ability to handle high loads, provide controlled force distribution, and withstand demanding operating conditions makes them a preferred choice for numerous applications. The flexibility in customization further enhances their value, allowing engineers to tailor them to specific requirements for optimal performance and reliability. As technology continues to advance and engineering demands become increasingly sophisticated, the versatility and precision offered by custom wave springs will undoubtedly play an even more vital role in the development of innovative solutions across a wide array of industries.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.