Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

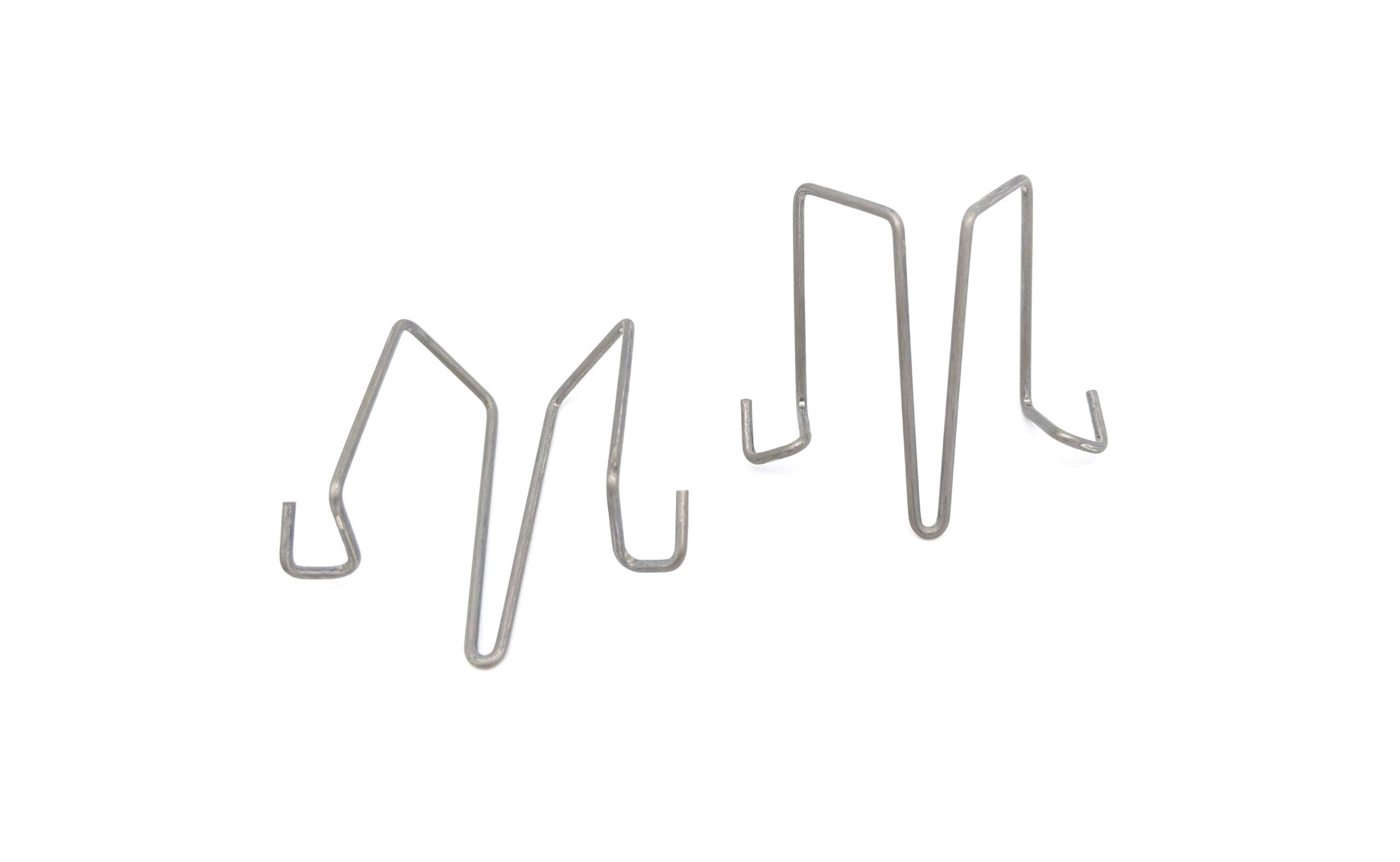

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Custom WAV springs are a specialized type of spring designed to meet unique application requirements. They offer exceptional performance and durability, making them ideal for demanding environments. This article delves

Custom WAV springs are a specialized type of spring designed to meet unique application requirements. They offer exceptional performance and durability, making them ideal for demanding environments. This article delves into the world of custom WAV springs, exploring their construction, advantages, and applications. We'll also discuss the factors to consider when choosing a custom spring for your specific needs and highlight the benefits of working with a reputable manufacturer.

WAV springs, also known as wave springs, are a type of helical spring that features a distinct wave-like profile. This unique design provides several advantages over traditional coil springs, including increased load capacity, reduced space requirements, and enhanced resistance to fatigue. Custom WAV springs are tailored to precise specifications, allowing engineers to optimize spring performance for specific applications.

Custom WAV springs offer a wide range of advantages that make them a preferred choice for numerous industries. Some key benefits include:

The versatility of custom WAV springs makes them suitable for a wide range of applications across various industries. Some common uses include:

When selecting a custom WAV spring for your application, several factors must be considered to ensure optimal performance and reliability. Some important considerations include:

Partnering with a reputable manufacturer specializing in custom WAV springs is crucial for ensuring the quality and reliability of your springs. A reputable manufacturer will offer the following benefits:

Custom WAV springs offer exceptional performance and durability, making them a valuable solution for demanding applications across various industries. By understanding the advantages of custom WAV springs, considering the factors involved in choosing the right spring, and working with a reputable manufacturer, you can ensure the success of your project.

Investing in custom WAV springs is an investment in reliability, performance, and longevity. By tailoring these springs to your specific needs, you can achieve optimal results and overcome the challenges of demanding applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.