Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of engineering and design, precision and functionality are paramount. Custom tension springs, with their unique ability to exert force when stretched, play a crucial role in countless

In the realm of engineering and design, precision and functionality are paramount. Custom tension springs, with their unique ability to exert force when stretched, play a crucial role in countless applications, from delicate medical devices to robust industrial machinery. These springs are meticulously engineered to meet specific requirements, offering unmatched flexibility and performance. Let's delve into the world of custom tension springs, exploring their characteristics, benefits, and the myriad ways they contribute to innovative designs.

Imagine a spring that extends effortlessly under a load, providing a consistent force throughout its stretch. This is the essence of a tension spring, a vital component in countless mechanical systems. Unlike compression springs, which resist compression, tension springs work by storing energy when stretched and releasing it as they contract. Their ability to deliver controlled tension makes them indispensable in various industries.

Custom tension springs offer a distinct advantage over standard, off-the-shelf options. Their tailored design allows them to meet the precise needs of specific applications, ensuring optimal performance and longevity. Here's a closer look at the key benefits of going custom:

Custom tension springs are ubiquitous in various industries, playing a crucial role in countless applications. Here are some notable examples:

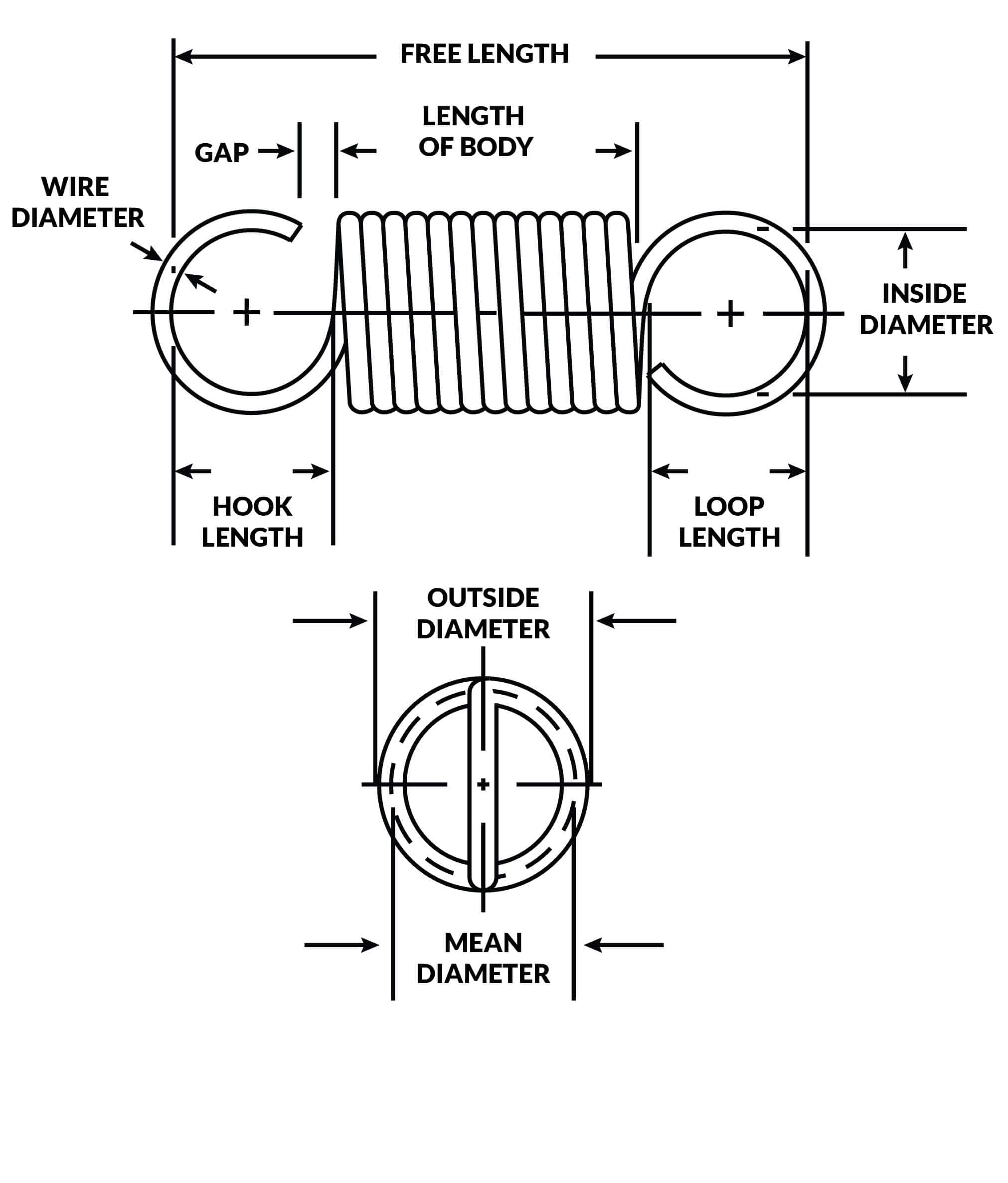

When designing a custom tension spring, several factors need to be taken into account to ensure optimal performance and reliability. These include:

Designing and manufacturing custom tension springs is a meticulous process requiring specialized knowledge and expertise. A reputable spring manufacturer will work closely with you to understand your application's unique requirements, ensuring that the spring meets your precise specifications. They will use advanced simulation software to model the spring's behavior under various loads and conditions, guaranteeing optimal performance and reliability. Additionally, they will utilize state-of-the-art manufacturing processes to achieve the highest level of precision and quality.

In conclusion, custom tension springs are not simply components; they are the embodiment of precision engineering, delivering tailored solutions to meet specific design needs. Their ability to exert controlled tension, coupled with their durability and versatility, makes them indispensable in various industries, from medical devices to heavy-duty machinery. Whether you're working on a groundbreaking innovation or simply need to optimize an existing design, custom tension springs offer the flexibility and reliability to take your projects to new heights.

As you embark on your next design project, consider the potential of custom tension springs. By partnering with a reputable spring manufacturer, you can leverage their expertise to create springs that perfectly match your application's requirements, enhancing performance, reliability, and longevity. Let custom tension springs be the key to unlocking the full potential of your designs, driving innovation and ensuring success.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.