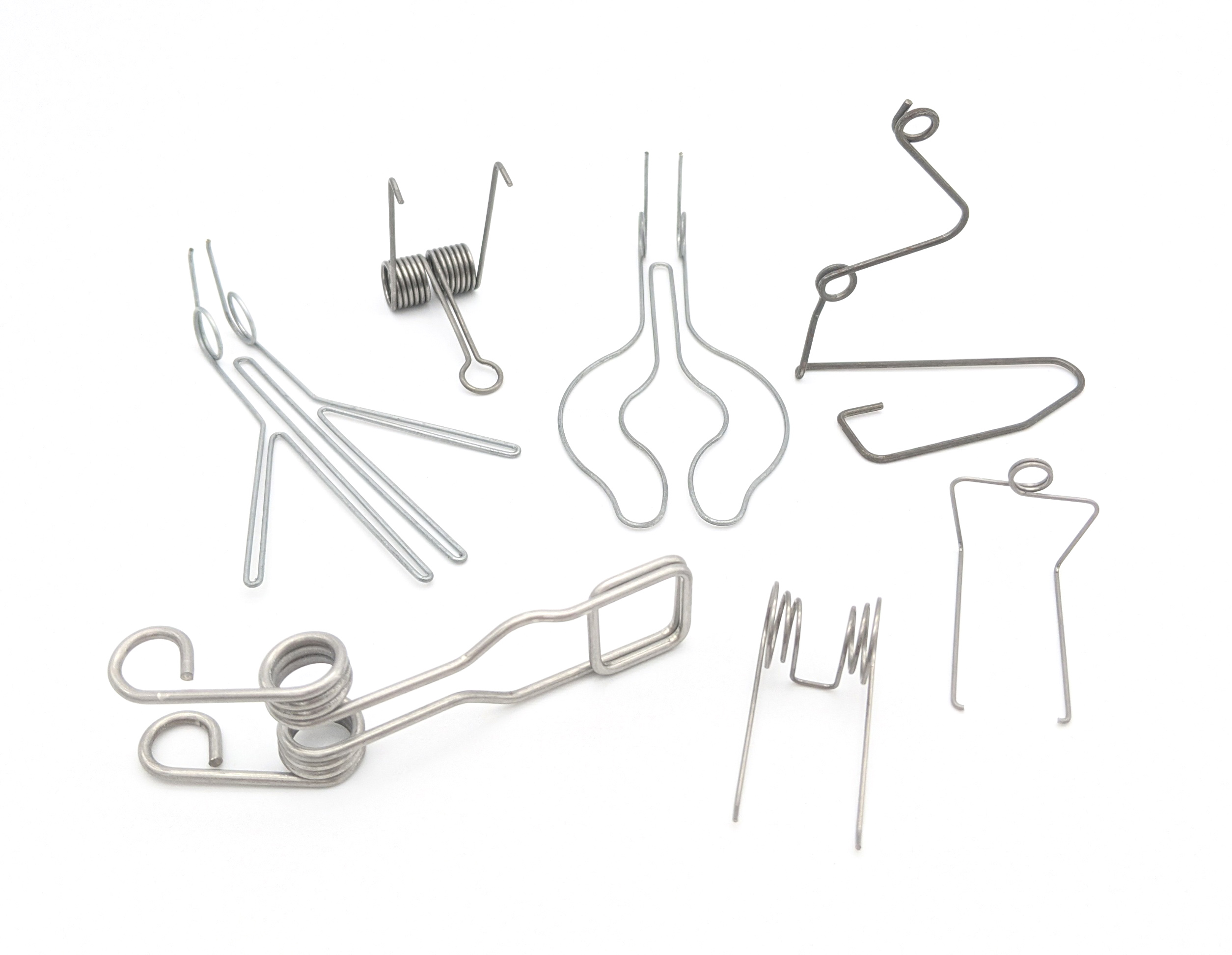

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the intricate world of mechanical systems, springs play a crucial role, acting as silent but essential components that provide force and motion. Among the various types of springs, constant

In the intricate world of mechanical systems, springs play a crucial role, acting as silent but essential components that provide force and motion. Among the various types of springs, constant springs stand out with their unique characteristic: maintaining a consistent force throughout their deflection cycle. This unwavering support makes them indispensable in diverse applications, from delicate precision instruments to robust industrial machinery. Let's delve into the fascinating world of constant springs, exploring their design, properties, and the remarkable applications that showcase their remarkable capabilities.

Unlike traditional springs, which exhibit a linear relationship between force and displacement, constant springs offer a consistent force output, regardless of how much they are compressed or extended. This unique feature arises from their ingenious design, often incorporating a combination of elements that create a non-linear force-displacement curve. This characteristic makes them ideal for applications where maintaining a constant force is paramount, ensuring smooth and reliable operation.

The constant force achieved by these springs is not magic; it's a result of careful engineering. The core concept behind their design is to distribute the load across multiple elements, each contributing to the overall force. This distribution ensures that even as the spring deflects, the force remains relatively consistent. One common approach is to use a series of springs, each with a different stiffness, arranged in a way that compensates for changes in displacement.

Constant springs, with their unwavering force, are employed in a wide array of applications, showcasing their versatility and reliability. They find their way into numerous sectors, demonstrating their ability to meet diverse demands.

In the realm of precision instruments, constant springs play a vital role, ensuring consistent and reliable performance. For example, in delicate measuring devices like calipers and micrometers, constant springs ensure uniform pressure on the measuring surfaces, guaranteeing accurate readings. They also contribute to the smooth operation of spring-loaded mechanisms in instruments like balances and scales.

Industrial machinery, with its heavy loads and demanding conditions, heavily relies on the strength and resilience of constant springs. They provide consistent force in systems like tensioning devices, ensuring even distribution of force in belts and chains. Constant springs also play a critical role in clutch mechanisms, ensuring smooth and reliable engagement of gears and shafts.

In the medical field, precision and reliability are paramount. Constant springs find their way into medical devices like surgical instruments, ensuring consistent tension and force for delicate procedures. They also contribute to the operation of spring-loaded mechanisms in drug delivery devices, guaranteeing accurate dosages.

The automotive industry also relies on constant springs for various applications. They are used in tensioning systems for timing belts, ensuring smooth and consistent operation of the engine. In braking systems, constant springs provide a consistent force, ensuring reliable brake pad engagement.

The unique characteristics of constant springs contribute to their widespread adoption in diverse applications.

Their primary advantage lies in their ability to provide a constant force throughout their deflection range, regardless of the load applied. This makes them highly reliable in situations where consistent force is critical.

The constant force ensures smooth and consistent operation in various mechanisms, minimizing fluctuations and vibrations. This is crucial for precision instruments and delicate applications.

The consistent force applied by constant springs reduces stress on other components, minimizing wear and tear. This contributes to increased lifespan and reliability of the mechanical systems.

Constant springs can be tailored to specific needs through modifications to their design. They can be made in various shapes and sizes to suit the requirements of the application.

Constant springs, often overlooked but always crucial, provide unwavering support in countless mechanical systems. Their ability to maintain a consistent force, ensuring smooth and reliable operation, makes them indispensable in a wide range of applications, from delicate precision instruments to robust industrial machinery. Their versatility and reliability make them a vital component in the advancement of mechanical technology. As we continue to innovate and explore new frontiers, constant springs will undoubtedly play an increasingly critical role in the future of mechanical systems.

Constant springs embody the quiet power of engineering, providing reliable and consistent force in various mechanical systems. They are a testament to the ingenuity and precision that can be achieved through thoughtful design and meticulous fabrication. Whether in delicate instruments, robust machinery, or intricate medical devices, constant springs stand as the unsung heroes of mechanical technology, contributing to our world's seamless and efficient operation.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.