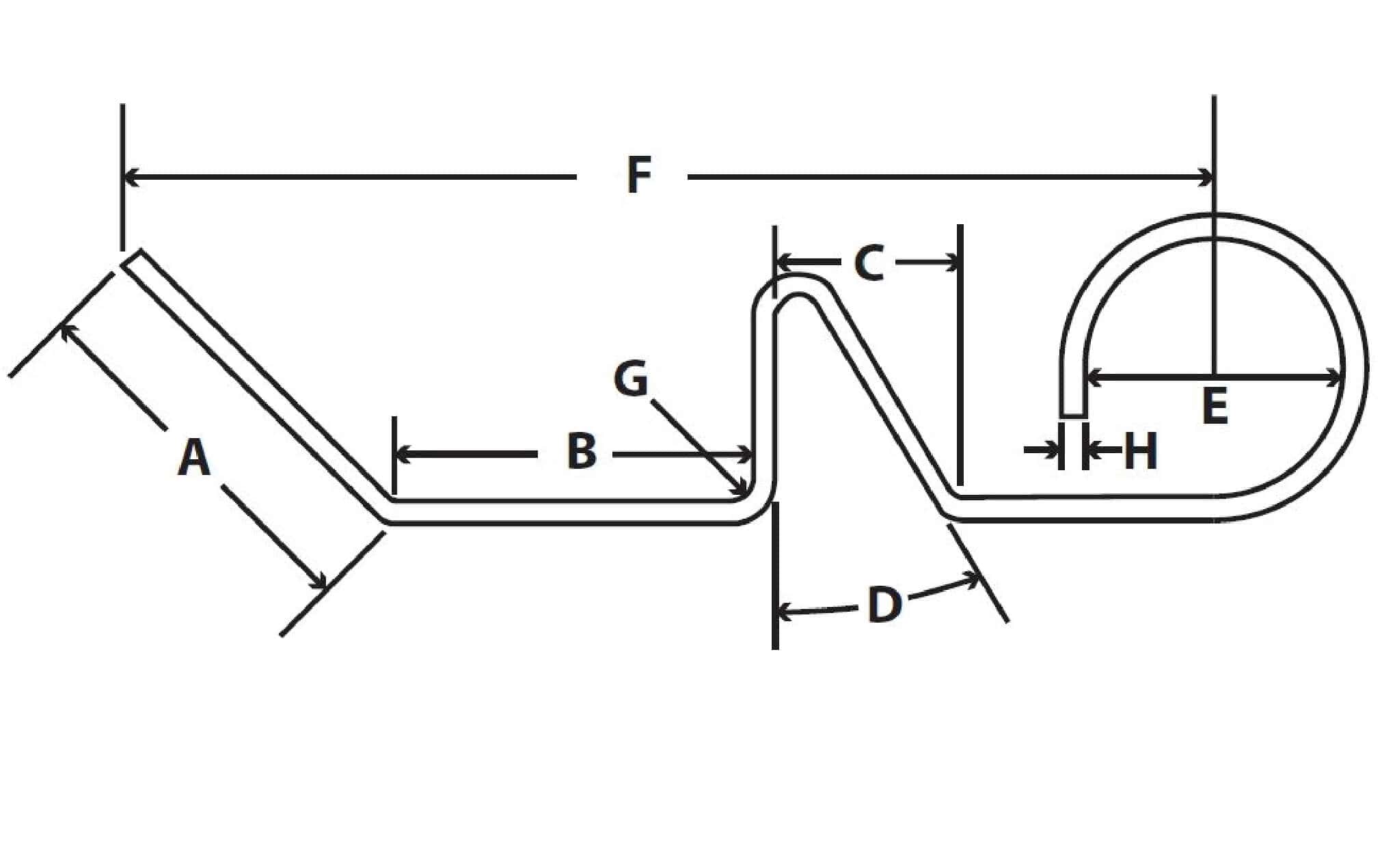

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, springs are ubiquitous, playing a crucial role in countless devices. From the simple act of closing a door to the intricate workings of a

In the world of mechanical engineering, springs are ubiquitous, playing a crucial role in countless devices. From the simple act of closing a door to the intricate workings of a car's suspension, springs provide a reliable force that ensures smooth operation and stability. Among the diverse types of springs, constant springs stand out for their unique ability to deliver a consistent force throughout their deflection cycle, making them ideal for applications where unwavering performance is paramount. This article delves into the fascinating world of constant springs, exploring their characteristics, applications, and the reasons why they are an indispensable component in various industries.

Imagine a spring that exerts the same amount of force, regardless of how much it is compressed or extended. That's the defining characteristic of a constant spring. Unlike conventional springs, where the force increases proportionally to the deflection, a constant spring maintains a steady force throughout its operating range. This remarkable ability stems from its carefully engineered design, which often involves a complex interplay of geometry and materials. The result is a spring that provides predictable and reliable performance, even under varying loads.

This consistent force makes constant springs particularly valuable in applications where maintaining a steady pressure or tension is critical. Consider a door closer, for instance. A constant spring ensures that the door closes with the same force, regardless of whether it's a gentle push or a forceful slam. This consistency not only promotes smooth operation but also enhances safety by preventing sudden or unpredictable closures. The same principle applies in other contexts, such as tensioning mechanisms for cables, belts, or chains, where a consistent force is essential for proper function.

To understand how constant springs achieve their unwavering performance, it's essential to delve into their design principles. The most common type of constant spring is the constant-force spring, which is a tightly rolled ribbon of spring steel. This ribbon, often known as a 'negator spring,' possesses a slightly concave cross-section. As it is coiled, it adopts a flat cross-section, but when unrolled, it returns to its former curved shape. This unique behavior is the key to its constant force property.

Imagine the ribbon being unrolled. As it unwinds, the force it exerts remains relatively consistent because the radius of curvature of the ribbon changes gradually. This controlled change in curvature ensures a steady output force, making it ideal for applications requiring a predictable and stable force over an extended deflection range.

The consistent force delivered by constant springs has earned them a place in a wide array of applications, spanning various industries. Here are a few prominent examples:

You've likely encountered constant springs in a familiar tool—the retractable tape measure. The spring mechanism inside the tape measure is designed to provide a constant force that retracts the tape smoothly and reliably. This constant force ensures a consistent speed of retraction, preventing the tape from snapping back too quickly or getting stuck. The constant spring in this application makes it a user-friendly tool.

Constant springs are also found in automotive applications, where they play a vital role in ensuring smooth operation and reliable performance. For example, some car door hinges incorporate constant springs to provide a consistent force that keeps the door closed. This prevents the door from rattling or slamming shut unexpectedly, contributing to a more comfortable driving experience.

The medical field also relies on constant springs for their precision and reliability. In medical devices, such as syringe pumps and infusion systems, constant springs are essential for delivering accurate and consistent medication dosages. Their predictable force ensures that the medication is delivered at the correct rate, promoting patient safety and therapeutic effectiveness.

The industrial world makes extensive use of constant springs in various machinery and equipment. For instance, tensioning mechanisms in conveyor belts often employ constant springs to maintain consistent belt tension, ensuring smooth and reliable material handling. This constant force is vital for preventing belt slippage, reducing wear and tear, and optimizing efficiency.

Even in the demanding realm of aerospace, constant springs have found a niche. In satellite systems and aircraft components, they are used for maintaining a consistent force on critical mechanisms. This consistency is crucial for ensuring reliable operation and safety in such high-pressure environments.

The consistent force delivered by constant springs offers numerous advantages over conventional springs, making them a preferred choice in many applications. Here are some key benefits:

The most significant advantage of constant springs is their predictable and reliable performance. They consistently deliver the same force regardless of their deflection, making them ideal for applications requiring unwavering accuracy. This consistency eliminates the potential for variations in force, ensuring smooth operation and enhanced safety.

Constant springs contribute to smooth operation by providing a steady force throughout their deflection cycle. This lack of abrupt force changes minimizes shock and vibration, enhancing the overall performance and durability of the device or system they are incorporated into.

The consistent force of constant springs can lead to increased efficiency. In applications like conveyor belts, maintaining a steady tension ensures smooth material handling, reducing energy losses and wear and tear. This improved efficiency translates into reduced maintenance costs and extended equipment lifespan.

Constant springs are incredibly versatile, lending themselves to a wide range of applications across various industries. Their adaptability makes them a valuable component in devices ranging from simple door closers to sophisticated medical instruments and aerospace systems.

Constant springs, with their unwavering force, have become indispensable components in countless applications. Their ability to deliver a predictable and reliable force has revolutionized how we design and operate a wide range of mechanical systems. From the simple act of closing a door to the intricate workings of medical devices and aerospace systems, constant springs are a testament to the ingenuity of engineering. Their consistent force, coupled with their versatility and reliability, has made them a cornerstone of modern technology, driving innovation and enhancing our daily lives.

As technology continues to evolve, constant springs will undoubtedly play an even greater role in shaping the future of mechanical systems. Their inherent ability to provide a steady and predictable force will remain a key advantage, ensuring smooth operation, enhanced reliability, and increased efficiency in a world that demands constant innovation.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.