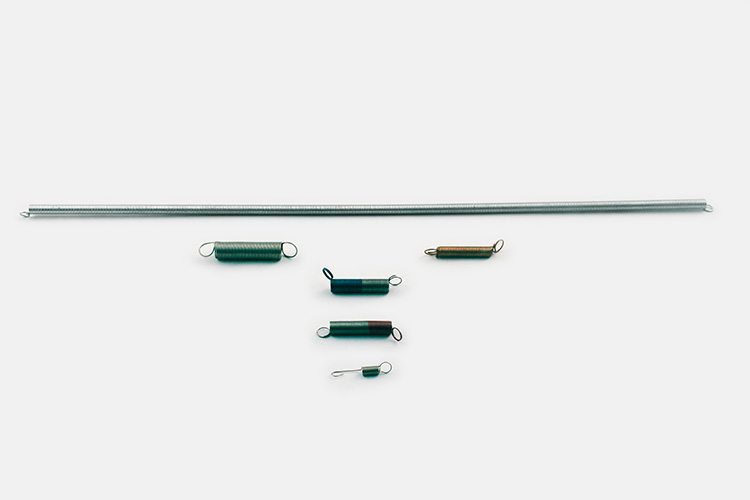

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, springs are ubiquitous, serving as crucial components in countless devices. But among the diverse array of spring types, constant springs stand out for their

In the world of mechanical engineering, springs are ubiquitous, serving as crucial components in countless devices. But among the diverse array of spring types, constant springs stand out for their unique ability to deliver consistent force throughout their deflection cycle. This characteristic makes them ideal for applications demanding predictable and reliable performance, from delicate instruments to heavy-duty machinery. Let's delve into the intricacies of constant springs, exploring their design, operation, and myriad applications.

Constant springs are a fascinating type of spring that maintain a constant force over a range of deflection. This seemingly simple concept holds immense power, enabling engineers to design systems that operate with unwavering precision. Unlike conventional springs, where force increases linearly with deflection, constant springs exhibit a remarkably consistent force profile. Imagine a spring that effortlessly lifts a weight, maintaining a constant upward force throughout its movement—this is the essence of a constant spring.

The magic behind constant springs lies in their unique design. Unlike conventional coil springs, which rely on the elasticity of a coiled wire, constant springs often utilize a combination of materials and geometries to achieve their remarkable force consistency. Here are some common approaches:

The consistent force characteristics of constant springs make them invaluable in a wide range of applications. Their unwavering performance is sought after in:

The inherent advantages of constant springs make them a preferred choice in many engineering applications:

Constant springs are a testament to the ingenuity of mechanical engineering, offering a solution to the challenge of achieving consistent force in diverse applications. They are not just simple springs; they are a sophisticated engineering marvel, enabling precision, reliability, and durability in everything from delicate instruments to complex machinery. As we continue to push the boundaries of engineering, constant springs will undoubtedly play a crucial role in shaping the future of technology, ensuring that our machines operate with unwavering precision and steadfast reliability.

The next time you encounter a device with a seemingly effortless and consistent force, remember the underlying power of a constant spring. These remarkable components are the unsung heroes of many applications, ensuring that our world operates with precision and unwavering dependability.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.