Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

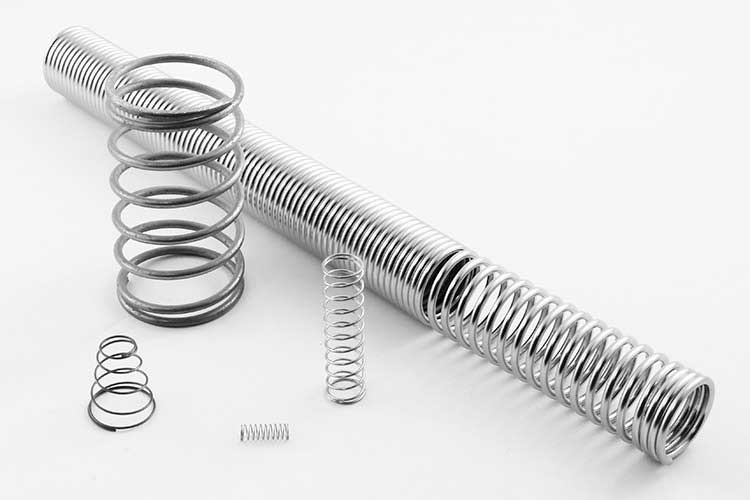

Conical compression springs, also known as volute springs, are a fascinating type of spring that offers unique advantages over traditional cylindrical compression springs. Their distinctive conical shape allows for a

Conical compression springs, also known as volute springs, are a fascinating type of spring that offers unique advantages over traditional cylindrical compression springs. Their distinctive conical shape allows for a greater compression range while maintaining consistent spring rate. This article delves into the intricacies of conical compression springs, exploring their design, applications, advantages, and disadvantages. Prepare to be captivated by the ingenuity of this spring design, and discover how it can be a valuable tool in your engineering endeavors.

Unlike their cylindrical counterparts, conical compression springs feature a gradually tapering coil diameter, creating a conical shape. This design has significant implications for their performance and applications.

Conical compression springs offer numerous advantages that make them ideal for specific applications. Let's explore some key benefits:

1. **Greater Compression Range:** Due to their conical shape, conical compression springs can compress significantly more than cylindrical springs of the same wire diameter and free length. This extended compression range is particularly advantageous in applications where substantial space constraints exist. Imagine a scenario where you need to compress a spring a considerable amount, but space is limited. A conical compression spring would be the perfect solution!

2. **Consistent Spring Rate:** Conical compression springs exhibit a remarkably consistent spring rate throughout their compression range. This means that the force required to compress the spring is more predictable and linear compared to cylindrical springs, which tend to exhibit a more variable spring rate. This consistent spring rate ensures reliable and predictable performance in various applications. It's like having a spring that behaves consistently and predictably, making design and engineering much easier.

3. **Reduced Stress Concentrations:** The tapered design of conical compression springs helps to distribute stress more evenly across the coils. This reduction in stress concentrations reduces the risk of fatigue and failure, increasing the spring's lifespan and reliability. Imagine a spring that can withstand repeated cycles of compression and extension without breaking. That's the beauty of a conical compression spring!

4. **Improved Stability:** The conical shape of these springs contributes to enhanced stability during compression. The tapered coils provide a more stable platform compared to cylindrical springs, which can sometimes wobble or become unstable under significant compression. This stability is crucial in applications where precision and reliability are paramount.

5. **Space Savings:** In some cases, conical compression springs can be more compact than their cylindrical counterparts, especially when compressed. This space-saving feature is particularly valuable in applications where space is limited. Imagine fitting a spring into a tight space. A conical compression spring, with its compact compressed form, might be the answer.

Conical compression springs are used in a wide range of applications, particularly where their unique advantages are crucial. Let's explore some common applications:

1. **Automotive Industry:** Conical compression springs are often employed in automotive suspension systems to provide a consistent spring rate and improved stability. They can handle significant forces and are well-suited for the demanding conditions of vehicle suspension.

2. **Industrial Machinery:** Conical compression springs find applications in industrial machinery and equipment, where they provide reliable force and shock absorption. Imagine a heavy-duty machine requiring a spring to absorb shocks. A conical compression spring can handle the load and provide reliable performance.

3. **Aerospace Industry:** The high-performance characteristics of conical compression springs make them suitable for aerospace applications where reliability and precision are critical. Think of aircraft components requiring robust and lightweight springs. Conical compression springs could be the perfect choice.

4. **Medical Devices:** Conical compression springs are found in various medical devices, where their precision and reliability are essential. Imagine a medical device requiring a spring to operate smoothly and precisely. A conical compression spring might be the ideal solution.

5. **Consumer Products:** Conical compression springs are even found in consumer products such as furniture, toys, and sporting goods. Their durability and versatility make them suitable for a wide range of applications.

While conical compression springs offer many advantages, they also have some drawbacks that should be considered:

1. **Higher Manufacturing Cost:** Manufacturing conical compression springs can be more complex and costly than producing cylindrical springs. The unique shape requires specialized tooling and more intricate manufacturing processes.

2. **Limited Availability:** Conical compression springs are not as readily available as cylindrical springs, which may require more time and effort to procure.

Conical compression springs are a remarkable example of engineering ingenuity. Their unique design offers distinct advantages over traditional cylindrical springs, particularly in applications demanding consistent spring rate, extended compression range, and reduced stress concentrations. While their manufacturing complexity and limited availability may pose some challenges, their exceptional performance characteristics make them a valuable tool for various engineering applications. So, next time you're designing a system requiring a spring, consider the possibilities of a conical compression spring. You might just be surprised by its potential!

In summary, conical compression springs offer a unique set of advantages that make them ideal for a wide range of applications. Their consistent spring rate, extended compression range, and improved stability make them a valuable tool in engineering. Although they have some drawbacks, their exceptional performance characteristics outweigh the disadvantages in many situations. As you explore your spring design needs, remember the possibilities of conical compression springs. They might just be the perfect solution for your next engineering challenge.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.