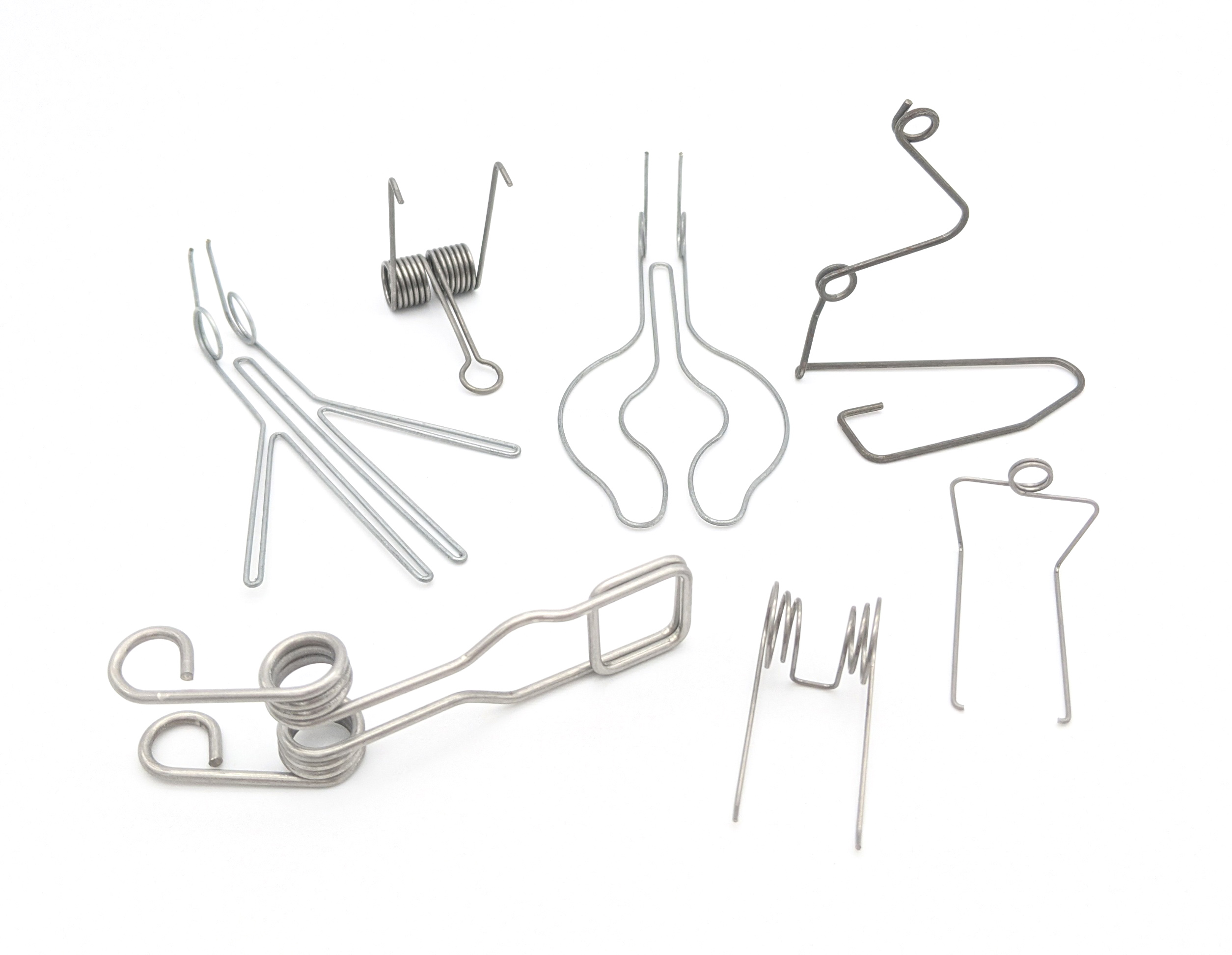

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Conical compression springs, also known as volute springs, are a unique type of spring designed to provide a smooth, consistent force throughout their compression cycle. Their tapered shape, with decreasing

Conical compression springs, also known as volute springs, are a unique type of spring designed to provide a smooth, consistent force throughout their compression cycle. Their tapered shape, with decreasing coil diameters, offers several advantages over traditional cylindrical springs. This article will delve into the design, characteristics, applications, and advantages of conical compression springs, providing you with a comprehensive understanding of this versatile spring type.

Conical compression springs, often referred to as volute springs, are a specialized type of helical spring characterized by their distinctive conical shape. Unlike cylindrical springs, where the coil diameter remains constant, conical springs feature a gradual decrease in coil diameter from one end to the other. This tapering design imparts unique characteristics and advantages, making them suitable for specific applications where traditional springs may fall short.

The tapered shape of a conical compression spring allows for a constant spring rate throughout its compression cycle. This means that the force required to compress the spring increases proportionally with the amount of compression. This characteristic, referred to as linear spring rate, is a key advantage in applications where predictable and consistent force is crucial.

Another noteworthy feature of conical springs is their ability to handle larger deflections or compressions compared to their cylindrical counterparts. The decreasing coil diameters allow for increased spring travel without encountering coil bind, where coils touch and impede further compression. This enhanced travel capability is highly beneficial in situations demanding significant spring movement.

The unique characteristics of conical compression springs make them ideally suited for a wide array of applications, some of which include:

The conical design of compression springs offers several notable advantages over traditional cylindrical springs, making them a preferred choice for various applications.

While conical compression springs offer a number of advantages, there are some factors to consider when selecting them for your application:

Conical compression springs, with their distinctive tapered shape and unique characteristics, provide a valuable alternative to traditional cylindrical springs in various applications. Their consistent spring rate, larger deflection capability, and improved stability make them a compelling choice for situations demanding reliable force control and predictable performance. As you weigh the advantages and considerations associated with conical compression springs, they can become an integral part of your design solutions.

In conclusion, conical compression springs offer a unique and versatile solution for various applications where consistent force, large deflections, and enhanced stability are desired. By understanding the advantages and considerations associated with these specialized springs, you can effectively incorporate them into your designs to achieve optimized performance and reliability.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.