Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

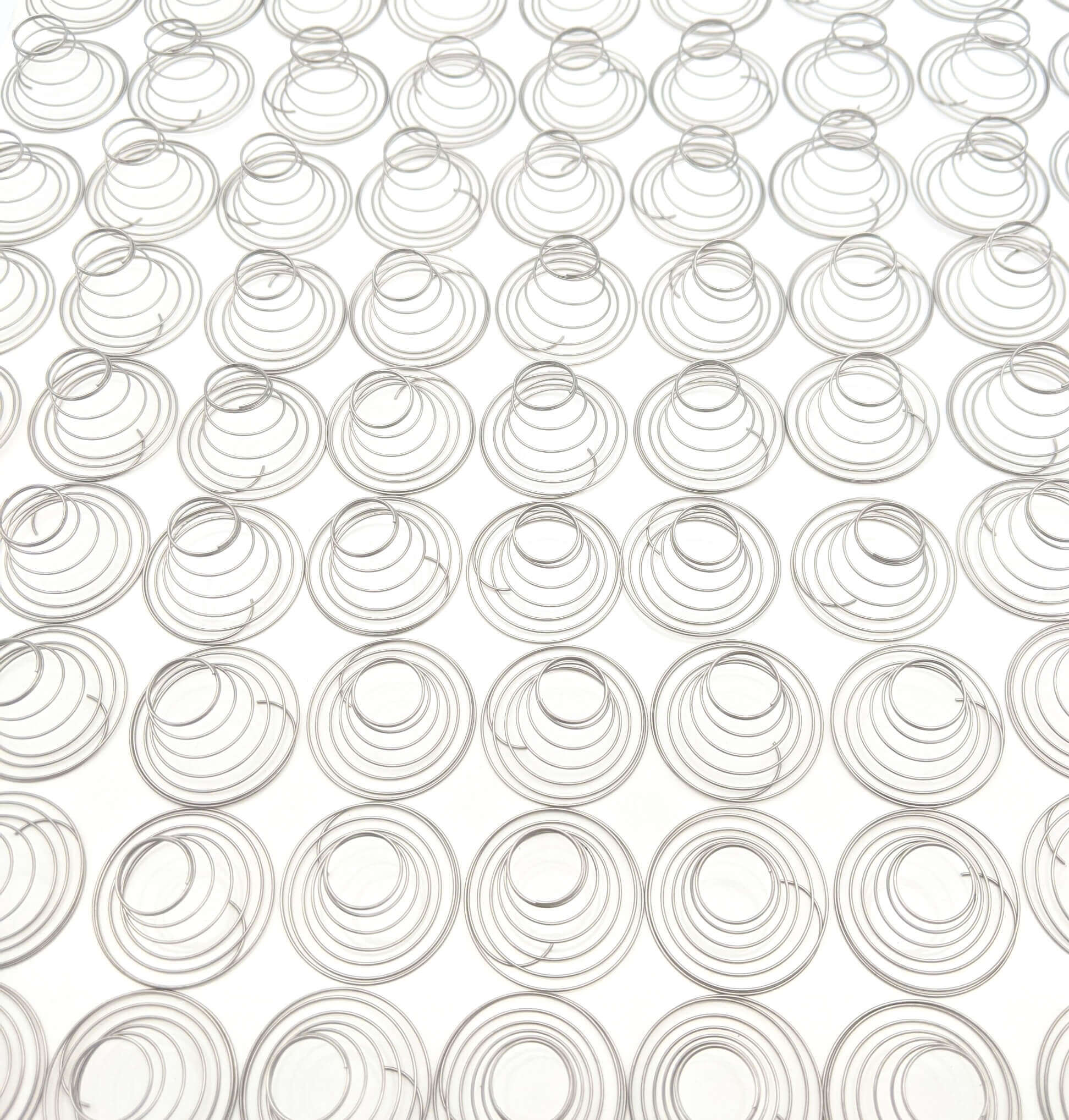

Concentric compression springs, commonly known as coil springs, are ubiquitous mechanical elements that store and release energy through elastic deformation. They are found in a wide array of applications, from

Concentric compression springs, commonly known as coil springs, are ubiquitous mechanical elements that store and release energy through elastic deformation. They are found in a wide array of applications, from simple tasks like holding a door open to complex engineering feats like shock absorption in vehicles. Understanding the design principles, materials, and applications of concentric compression springs is essential for engineers and designers to effectively utilize these components in various mechanical systems.

The design of a concentric compression spring is governed by several key parameters, including wire diameter (d), spring index (C), number of active coils (n), free length (Lf), solid height (Ls), and material properties. These parameters interact to determine the spring's stiffness (k), load capacity, and overall performance.

The spring index (C), defined as the ratio of the mean coil diameter (D) to the wire diameter (d), significantly influences the spring's characteristics. A higher spring index leads to a more flexible spring with lower stiffness, while a lower index results in a stiffer spring. The number of active coils (n) directly affects the spring's overall length and load capacity. More coils provide greater extension and load-bearing capability.

The material used for the spring wire is critical to its performance. Spring steel, known for its high strength and resilience, is a common choice. Other materials, such as stainless steel, phosphor bronze, and music wire, may be selected based on specific application requirements like corrosion resistance or high temperature stability.

Concentric compression springs are incredibly versatile and find applications in a wide range of industries and devices. Some common examples include:

When selecting and using concentric compression springs, it is crucial to consider the following factors:

Concentric compression springs are essential components in countless mechanical systems, enabling a wide range of functionalities. Their design principles, material selection, and applications are crucial to engineers and designers for creating robust and reliable mechanisms. Understanding the considerations for selecting and using these springs ensures proper performance, safety, and long-term reliability in various applications.

By carefully considering the design parameters, material properties, and application requirements, engineers can effectively utilize concentric compression springs to optimize the functionality and reliability of mechanical systems. As technology continues to advance, these versatile components will undoubtedly continue to play a vital role in various industries, contributing to innovation and progress.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.