Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

When it comes to the world of springs, two types stand out: compression springs and tension springs. While they both use elastic force to create movement, they function in opposite

When it comes to the world of springs, two types stand out: compression springs and tension springs. While they both use elastic force to create movement, they function in opposite ways. Understanding the differences between these two fundamental spring types is crucial for choosing the right one for your application. This article will explore the workings, applications, and considerations for each, helping you navigate the spring selection process with confidence.

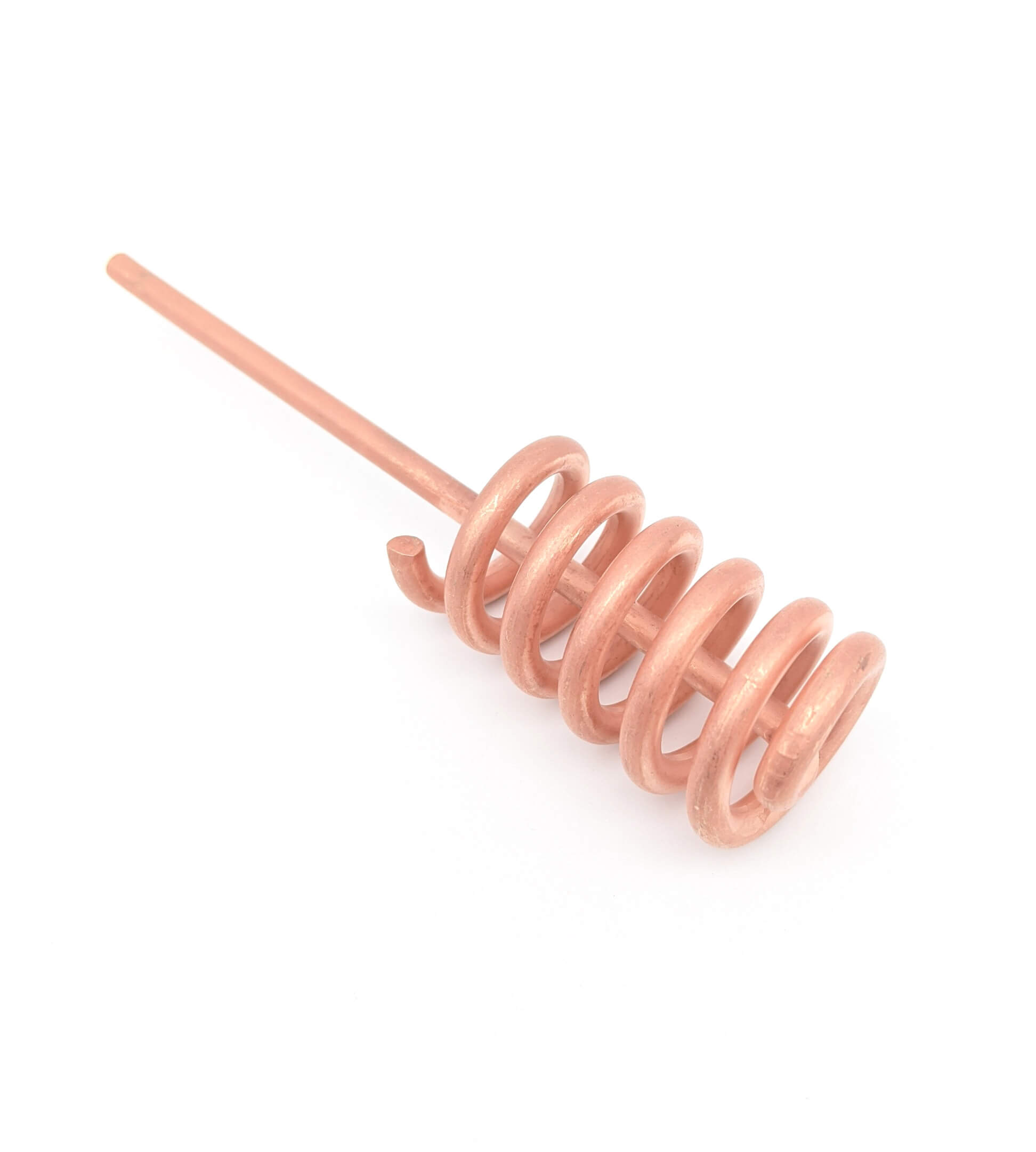

Imagine a coil spring sitting on a surface. When you push down on it, the coils compress closer together. This is the essence of a compression spring—it absorbs energy by shortening under pressure. Think of the spring inside a ballpoint pen, or the springs supporting your car's suspension. They are designed to resist forces pushing them inwards, storing the energy in their compressed state.

Now picture the same spring, but this time, imagine you're pulling it upwards. The coils stretch out and become longer. This is the role of a tension spring—it absorbs energy by extending under a pulling force. Tension springs are commonly found in retractable dog leashes, clothespins, and even some types of door hinges. They work by resisting forces pulling them outwards, storing the energy in their extended state.

The fundamental difference between compression and tension springs lies in their primary function. Compression springs are made to withstand compressive forces and become shorter, while tension springs are made to withstand tensile forces and become longer.

Here’s a table summarizing the key differences between the two types:

| Feature | Compression Spring | Tension Spring |

|---|---|---|

| Function | Resists compression | Resists tension |

| Load Application | Force pushing on the spring | Force pulling on the spring |

| Movement | Shortens in length | Extends in length |

| Typical Applications | Suspension systems, door closers, ballpoint pens | Retractable leashes, clothespins, door hinges |

The choice between a compression spring and a tension spring depends heavily on the specific requirements of your application. Consider the following factors:

While compression and tension springs are the basic building blocks, there are many variations and specialized applications of each. For example:

Compression and tension springs are indispensable components in countless applications, each offering unique functionalities. Understanding the differences between these two types is crucial for selecting the right spring for your needs. When considering your application, think about the direction of force, space restrictions, and load requirements. With careful analysis and knowledge of their properties, you can ensure that you’re using the right spring for the job, ensuring optimal performance and functionality in your design.

Remember, the spring world is vast, and there are many specialized types beyond compression and tension springs. Consulting with a spring specialist or manufacturer can provide valuable expertise in navigating the nuances of spring selection for your specific needs. Ultimately, choosing the right spring is about understanding the forces at play and selecting the type that best meets your application’s demands.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.