Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

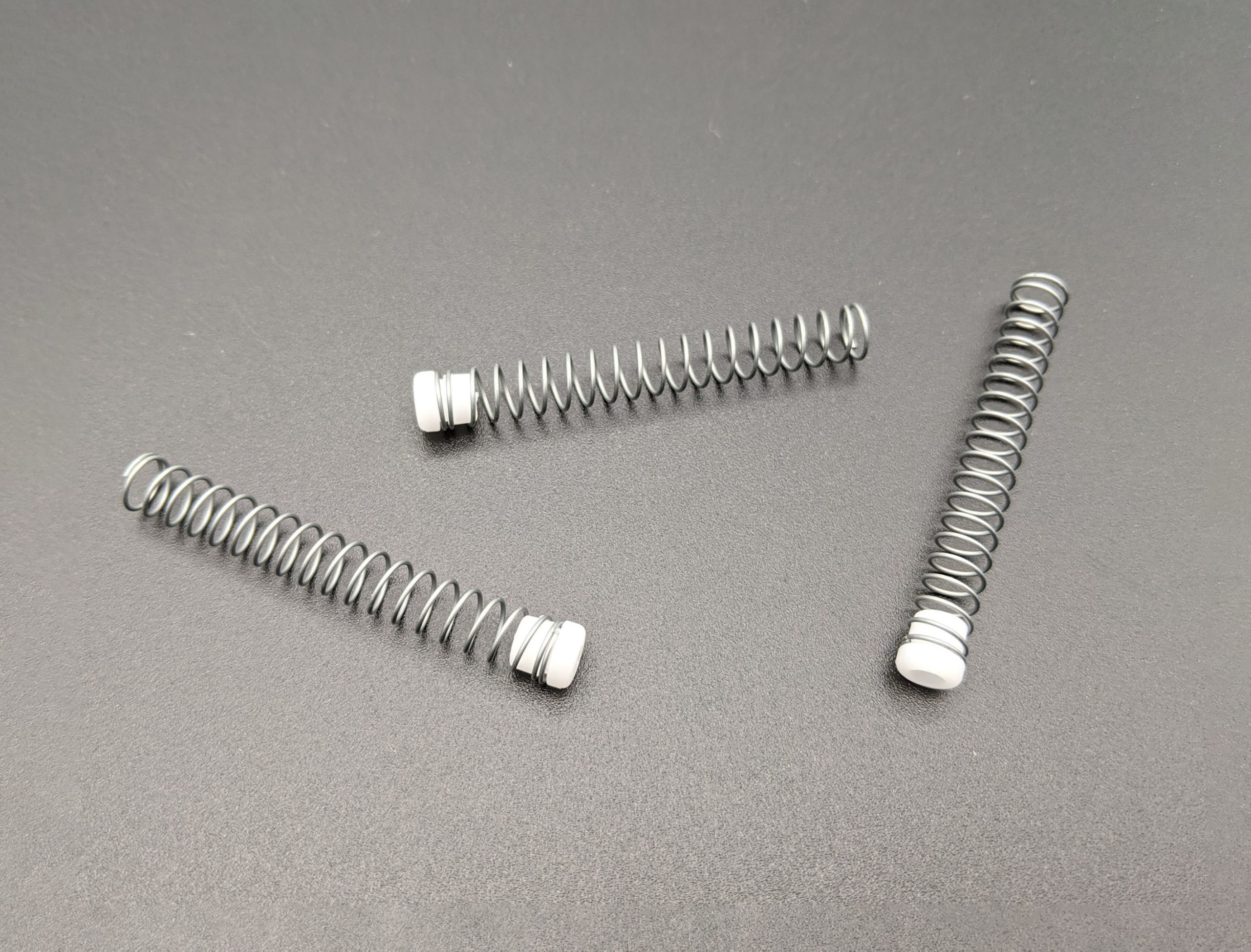

Compression springs, those ubiquitous coiled wonders, are often taken for granted. From the simple act of pushing a button to the complex mechanisms of machinery, compression springs play a vital

Compression springs, those ubiquitous coiled wonders, are often taken for granted. From the simple act of pushing a button to the complex mechanisms of machinery, compression springs play a vital role in our world. They store energy, absorb shock, and provide a reliable force for countless applications. Understanding the fundamentals of compression spring design, their characteristics, and their varied applications is crucial for anyone involved in engineering or manufacturing. This article delves into the fascinating world of compression springs, exploring their intricacies and highlighting their significance in modern technology.

Compression springs, characterized by their ability to resist compressive forces and store mechanical energy, are integral components in various engineering applications. Imagine the spring in a ballpoint pen, providing the necessary force for the ballpoint to retract. Now envision the coil springs within a car's suspension system, absorbing bumps and ensuring a smooth ride. These examples demonstrate the versatility and importance of compression springs in our everyday lives.

The design of a compression spring is a delicate dance between material properties, geometry, and intended application. The core principles governing compression spring behavior include:

The choice of material for a compression spring is paramount to its performance and longevity. Spring steel, renowned for its resilience and ability to withstand repeated stress cycles, is the most common material for compression spring applications. Different grades of spring steel, each with varying levels of carbon content and tempering, offer specific properties for various applications. High-carbon spring steel provides exceptional strength and fatigue resistance, making it suitable for demanding applications. However, selecting the appropriate spring steel for a specific application necessitates a thorough understanding of the expected loads, operating temperatures, and potential environmental factors.

Compression springs find applications across diverse fields, playing vital roles in everything from everyday objects to advanced machinery. Here are a few examples:

While traditional compression springs are still widely used, advancements in materials science and manufacturing have paved the way for new and innovative compression spring designs. These include:

From the simplest of everyday objects to the most advanced technological marvels, compression springs are indispensable components. Their ability to store energy, absorb shock, and provide precise force makes them an essential tool for engineers and designers. As technology continues to evolve, the field of compression spring design and manufacturing will undoubtedly continue to innovate, pushing the boundaries of what is possible with these remarkable components.

The world of compression springs is vast and multifaceted, encompassing a range of designs, materials, and applications. Understanding the fundamental principles of compression spring behavior, including spring rate, free length, wire diameter, coil diameter, and number of coils, is crucial for selecting the right spring for a given application. By carefully considering these parameters, engineers and designers can ensure the optimal performance and longevity of their systems. As technology continues to advance, the field of compression spring design will undoubtedly continue to evolve, leading to even more innovative and impactful solutions.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.