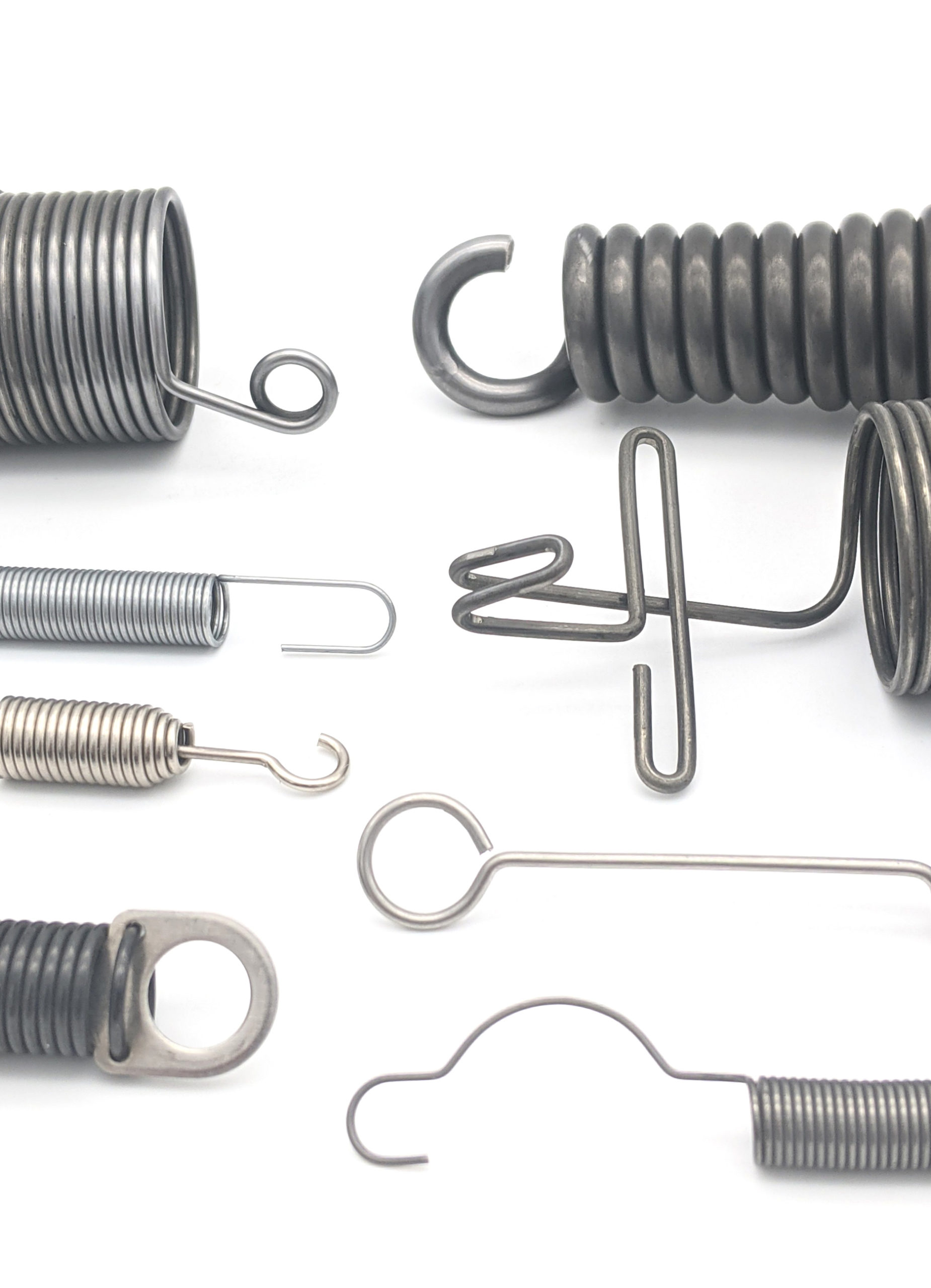

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered what makes a door spring back shut, or how a car suspension manages to absorb bumps in the road? The answer lies in the humble, yet

Have you ever wondered what makes a door spring back shut, or how a car suspension manages to absorb bumps in the road? The answer lies in the humble, yet indispensable, compression spring. These seemingly simple coiled metal devices are the unsung heroes of countless mechanical systems, quietly working behind the scenes to provide essential support, stability, and movement. From the tiniest of gadgets to the largest of machinery, compression springs are the backbone of our technological world, enabling countless functions that we take for granted.

A compression spring, as its name suggests, is a type of spring designed to resist compression or pushing forces. It's typically made of coiled wire, with the coils tightly wound together and often having a gap between them when in their unloaded state. When a load is applied, the coils compress, storing energy within the spring. This stored energy is then released when the load is removed, causing the spring to return to its original length. It's like a coiled-up rubber band, but much more robust and capable of withstanding greater forces.

The magic of compression springs lies in their ability to convert applied force into stored potential energy. This is possible due to the inherent elastic properties of the materials used to make them, usually spring steel. When compressed, the spring resists the force by deforming its shape, but within a certain limit, it will return to its original form when the force is removed. This elasticity is key to their function. Imagine squeezing a sponge. You're applying force, and the sponge compresses. When you release the pressure, the sponge expands back to its original shape. Compression springs work on a similar principle.

Compression springs are ubiquitous in modern life, playing a vital role in countless applications. We encounter them daily, though often without realizing their presence. Here are just a few examples:

**In the Home:**

**In Transportation:**

**In Technology and Industry:**

Compression springs come in a variety of designs and shapes, tailored for specific applications. Some common types include:

The selection of a compression spring for a particular application involves considering various factors, including:

It's important to consult with a spring manufacturer or engineer to ensure that the selected compression spring is suitable for the intended application and meets all necessary specifications.

While compression springs are incredibly versatile and reliable, safety considerations must be kept in mind when designing, manufacturing, and using them. Here are a few points to remember:

Compression springs are constantly evolving, with advancements in materials, manufacturing processes, and design leading to enhanced performance and durability. For example, the use of advanced materials like carbon fiber or shape memory alloys is opening up new possibilities for spring applications. The development of 3D printing technology is also revolutionizing spring production, allowing for complex geometries and customized designs. As we continue to push the boundaries of technology, compression springs will undoubtedly play a vital role in shaping the future of our mechanical world.

From the smallest of devices to the largest of machines, compression springs are the invisible forces that make our modern world function. These unassuming coiled metal devices play a critical role in countless applications, ensuring smooth operation, reliable performance, and safety. As our technological landscape continues to evolve, the humble compression spring will remain an indispensable component, silently powering our world for generations to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.