Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

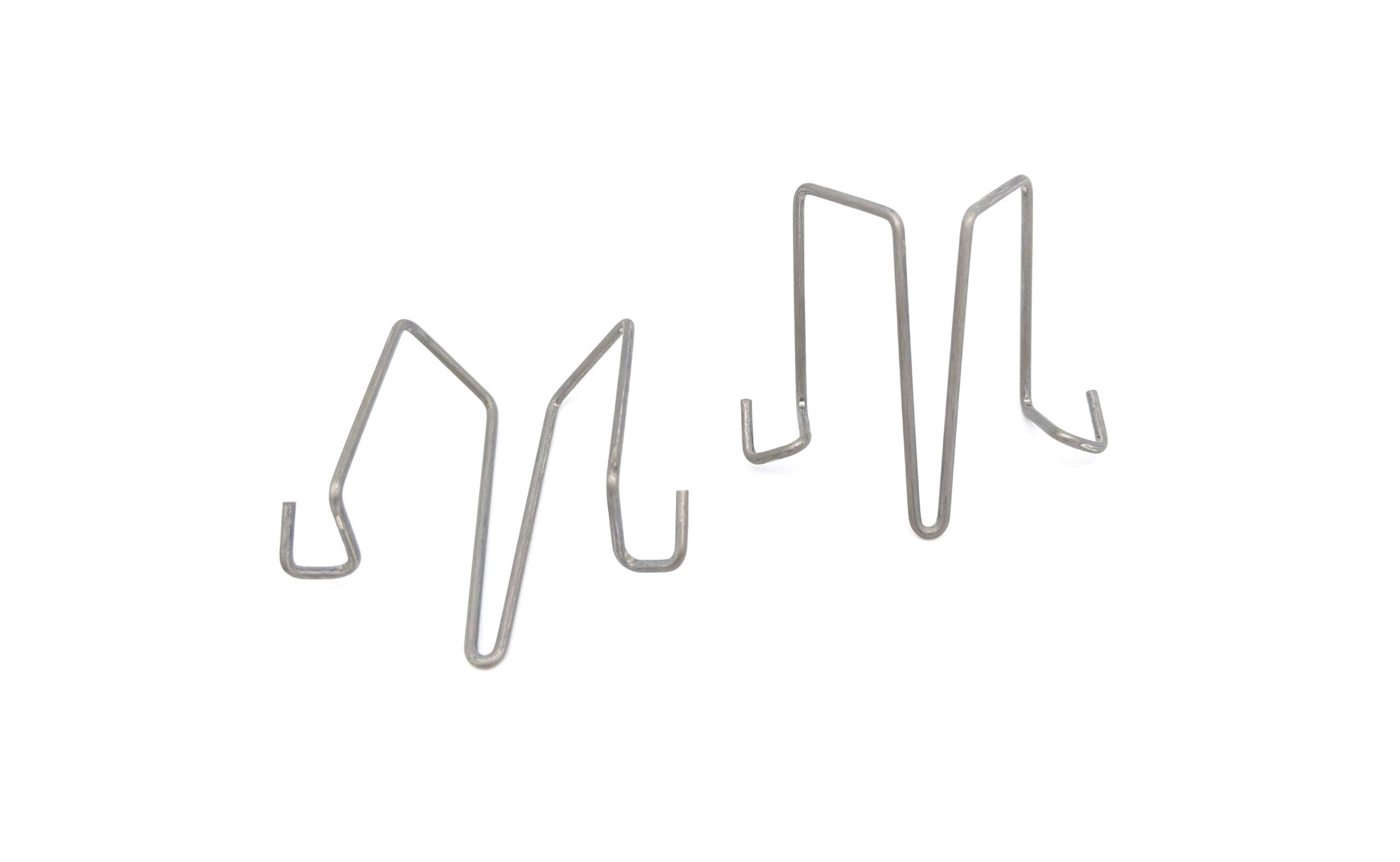

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, those ubiquitous coiled wonders of metal, are often overlooked, yet they play a vital role in countless applications. From the simple act of closing a door to the

Compression springs, those ubiquitous coiled wonders of metal, are often overlooked, yet they play a vital role in countless applications. From the simple act of closing a door to the complex workings of machinery, compression springs provide the essential force that makes our world function smoothly. These seemingly simple devices are actually marvels of engineering, with their design and properties meticulously crafted to meet specific needs. Let's delve into the fascinating world of compression springs, uncovering their secrets and appreciating their significance in our daily lives.

At their core, compression springs are helical coils made from spring steel, often with a circular cross-section. They are designed to resist compression forces, meaning they shorten when a load is applied. Imagine a springy coil like a Slinky – that's essentially what a compression spring is, though they come in various shapes, sizes, and strengths.

The magic of a compression spring lies in its ability to store and release energy. When you compress the spring, you are storing potential energy within its coils. As the spring returns to its original shape, it releases this energy. This simple principle is the foundation for countless applications, from shock absorbers in cars to the delicate mechanisms in watches.

The behavior of a compression spring is governed by a fundamental principle known as Hooke's Law. This law states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. In simpler terms, the more you compress a spring, the greater the force it will push back with. This linear relationship between force and displacement makes compression springs incredibly predictable and reliable.

The stiffness or spring rate of a compression spring is a crucial characteristic that determines how much force it will exert for a given amount of compression. This rate is measured in units of force per unit length, such as pounds per inch or Newtons per meter. A higher spring rate indicates a stiffer spring, requiring more force to compress it. Engineers carefully select spring rates based on the specific application to ensure proper performance.

Compression springs are truly versatile components, found in a staggering array of applications. Here are just a few examples:

Compression springs play a vital role in the suspension systems of vehicles, providing a comfortable ride by absorbing shocks from bumps and uneven roads. They are also used in clutches, brakes, and engine valves.

From heavy-duty presses to delicate assembly lines, compression springs are crucial for providing controlled movement, clamping forces, and shock absorption. They are used in everything from power tools to industrial robots.

Compression springs are hidden in countless consumer products, often silently working behind the scenes. They are found in door hinges, pens, retractable pens, toy guns, and even the pop-up mechanism in toasters. They even power the springs in retractable dog leashes, allowing you to control your furry friend.

Compression springs find applications in medical devices, where their reliability and precise force output are critical. They are used in surgical instruments, medical beds, and even in some prosthetic limbs.

Even in the world of aerospace, compression springs are essential components. They are used in aircraft landing gear, satellite mechanisms, and even in space shuttles.

Designing and manufacturing compression springs requires a deep understanding of materials, spring geometry, and the desired performance characteristics. Engineers meticulously select the wire diameter, coil diameter, number of coils, and material to achieve the desired spring rate, load capacity, and fatigue life.

Compression springs can be made from a wide range of materials, with spring steel being the most common choice. Other materials such as stainless steel, phosphor bronze, and titanium are used in applications requiring corrosion resistance or specific electrical properties. The choice of material also impacts the spring's ability to withstand fatigue and environmental conditions.

Selecting the right compression spring for your application is crucial for optimal performance. Several factors must be considered:

Compression springs are often unseen, yet they are essential components that make our world function smoothly. Their ability to store and release energy, combined with their reliability and versatility, make them indispensable in countless applications. From the simple act of closing a door to the complex workings of machinery, compression springs are the unsung heroes of modern mechanics.

Next time you encounter a spring, take a moment to appreciate the intricate engineering behind its design and the essential role it plays. Whether it's the gentle push from a door hinge or the powerful force of a suspension system, compression springs are a testament to human ingenuity and their impact on our daily lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.