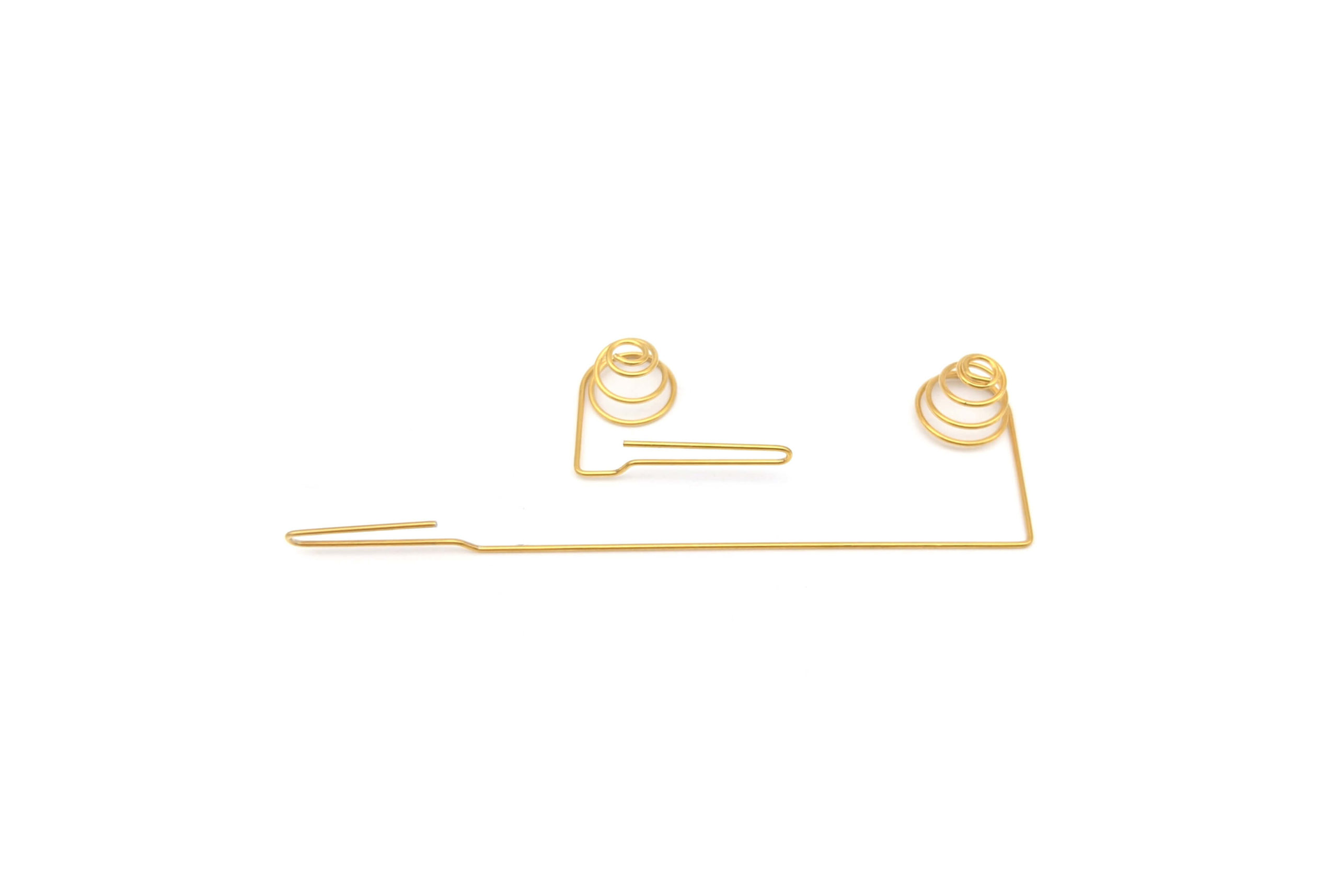

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs are ubiquitous in our daily lives, quietly working behind the scenes to ensure the smooth operation of countless devices and systems. From the humble ballpoint pen to the

Compression springs are ubiquitous in our daily lives, quietly working behind the scenes to ensure the smooth operation of countless devices and systems. From the humble ballpoint pen to the sophisticated suspension system of a car, these resilient coils of metal play a crucial role in our modern world. Their ability to store and release mechanical energy, providing a controlled and predictable force, makes them indispensable in a wide range of applications. In this article, we will delve into the fascinating world of compression springs, exploring their construction, properties, and the myriad ways they enhance our lives.

A compression spring, as the name suggests, is designed to resist compression forces. When a load is applied to a compression spring, it contracts, storing energy within its coiled structure. The force exerted by the spring is directly proportional to the amount of compression, a principle known as Hooke's Law. This predictable relationship between force and compression makes compression springs incredibly versatile for a wide range of applications.

Compression springs are typically made from spring steel, a specialized type of steel known for its high elasticity and resilience. The steel is carefully chosen for its strength and ability to withstand repeated compression cycles without fatigue. The spring wire is then wound into a helical coil, forming the characteristic shape of a compression spring. The number of coils, the wire diameter, and the coil diameter all influence the spring's stiffness or spring rate, which determines how much force is required to compress it a given distance.

Compression springs can be further categorized based on their design and construction. Common types include:

The choice of spring type depends heavily on the specific application and the required force and compression characteristics. For example, a linear spring might be suitable for a simple door hinge, while a variable rate spring might be needed for a shock absorber in a car.

Compression springs are truly ubiquitous, finding applications in virtually every industry. Here are just a few examples:

It's impossible to list every application of compression springs, as they are truly essential components in a vast array of devices and systems.

Compression springs are more than just simple coiled pieces of metal. They are the unsung heroes of modern engineering, quietly performing essential functions that make our lives easier, safer, and more productive. Their ability to store and release energy, provide predictable forces, and withstand repeated cycles makes them invaluable across numerous industries. Their versatility and reliability have earned them a prominent place in the world of mechanical design, ensuring their continued importance for generations to come.

In conclusion, compression springs are essential components in the intricate tapestry of modern engineering. They are the silent workhorses that contribute to the smooth operation of countless devices and systems. Their ability to provide controlled and predictable forces, combined with their inherent resilience and versatility, makes them indispensable in a wide range of applications. As we continue to advance technologically, compression springs will undoubtedly continue to play a vital role in shaping the future of innovation. Their unassuming nature belies their profound importance, a testament to the power of simple but elegant solutions in the world of engineering.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.