Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, those ubiquitous coiled wonders, are often overlooked, yet they play a vital role in countless applications. From the humble clothes peg to sophisticated industrial machinery, these springs silently

Compression springs, those ubiquitous coiled wonders, are often overlooked, yet they play a vital role in countless applications. From the humble clothes peg to sophisticated industrial machinery, these springs silently work their magic, providing essential forces and ensuring smooth operation. Their ability to absorb energy and release it in a controlled manner makes them indispensable in a wide range of industries, from automotive and aerospace to medical devices and consumer goods. But how do these unassuming components work, and what makes them so effective?

At its core, a compression spring is a helical coil of wire designed to absorb energy when compressed and release it when the force is removed. It's like a miniature energy storage device, silently working behind the scenes. The spring's ability to exert force is determined by its design parameters, including the wire diameter, coil diameter, number of coils, and the material used. The most common material for compression springs is spring steel, chosen for its strength and resilience.

Imagine a simple clothes peg. The spring inside pushes the two arms together, ready to grip. When you press the arms together, the spring compresses, storing energy. As you release your grip, the spring's stored energy pushes the arms back apart, clamping the clothe onto the line. This simple principle of compression and release is at the heart of every compression spring application.

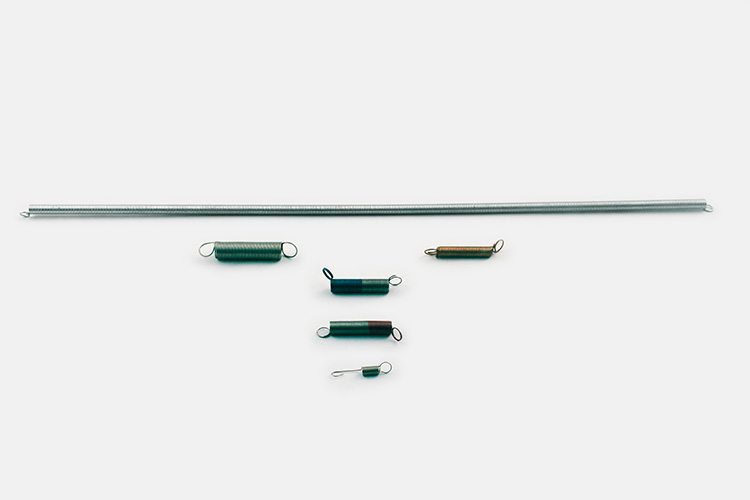

Compression springs come in a variety of shapes and sizes, each designed to meet specific requirements. You'll find them in different configurations, such as:

The versatility of compression springs makes them essential components in numerous industries and applications. Here are a few examples:

The use of compression springs offers numerous advantages, making them a valuable choice for engineers and designers:

Selecting the appropriate compression spring for a specific application is crucial for optimal performance and reliability. Several factors need to be considered, including:

Compression springs are often overlooked, yet their contribution to the world of engineering is immense. They are the unsung heroes of mechanical design, providing crucial forces and ensuring smooth operation in countless applications. Their versatility, reliability, and cost-effectiveness make them a valuable asset for engineers and designers seeking solutions for a wide range of challenges. So next time you encounter a simple clothes peg or a sophisticated piece of machinery, remember the little coiled wonders working silently behind the scenes, ensuring things function smoothly and reliably.

The next time you encounter a simple clothes peg or a sophisticated piece of machinery, remember the little coiled wonders working silently behind the scenes, ensuring things function smoothly and reliably. Compression springs may be small, but their impact is significant.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.