Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

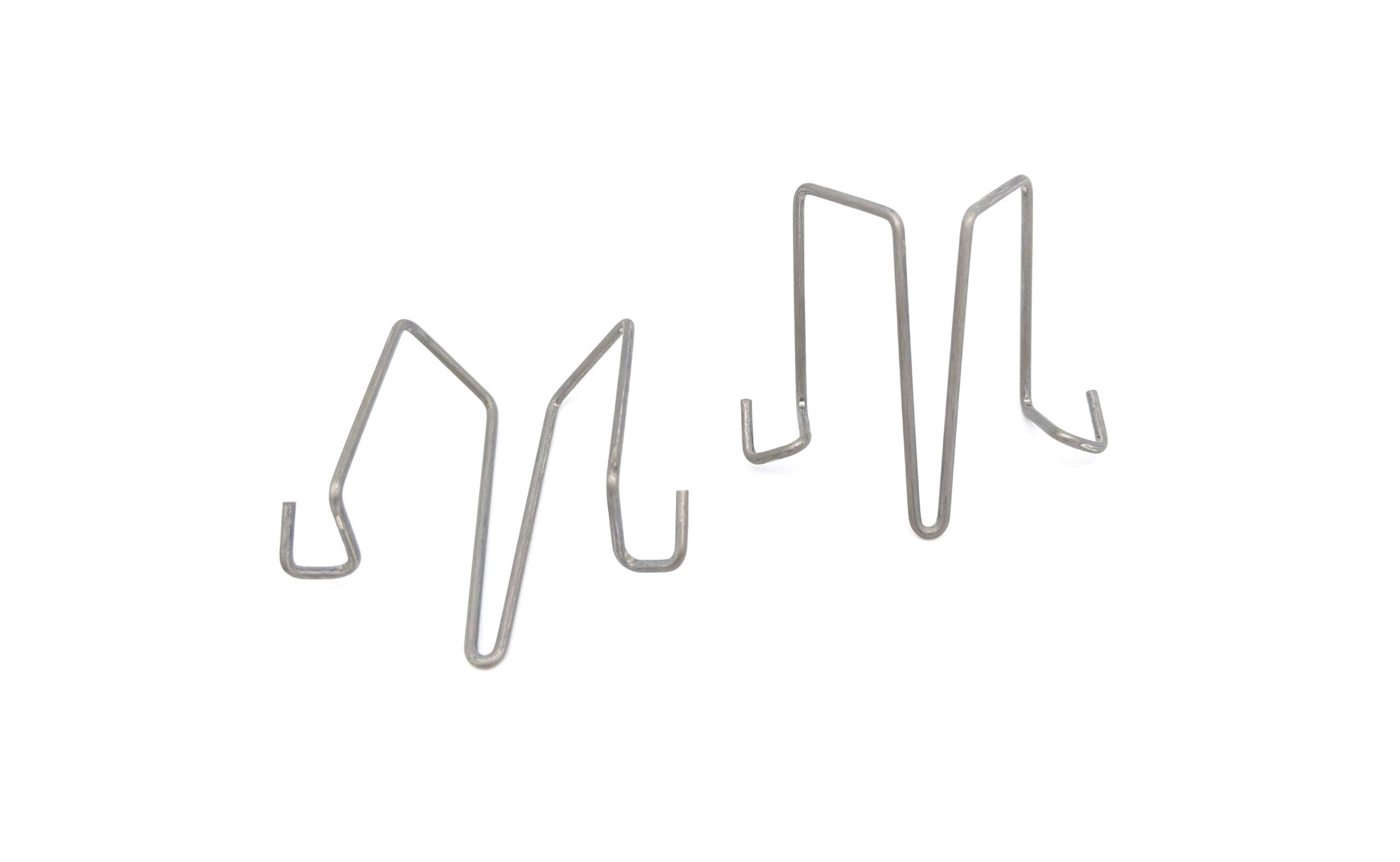

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a world without springs. No bouncy castles, no smooth car rides, no satisfying click of a pen. These ubiquitous components are the unsung heroes of mechanical design, silently working

Imagine a world without springs. No bouncy castles, no smooth car rides, no satisfying click of a pen. These ubiquitous components are the unsung heroes of mechanical design, silently working to provide force, absorb energy, and ensure smooth operation in countless applications. Among the many types of springs, compression springs stand out as the workhorses, serving as the backbone of everything from everyday appliances to complex industrial machinery.

A compression spring, as the name suggests, is designed to operate under a compressive load. When a force is applied to it, the spring compresses, storing potential energy. Once the force is released, the spring expands back to its original length, releasing the stored energy. This simple yet fundamental principle makes compression springs indispensable in a wide variety of applications.

The magic of compression springs lies in their helical design. They are essentially coils of wire, tightly wound around a central axis. This coiled structure allows the spring to absorb and release energy efficiently. The key characteristics of a compression spring that determine its performance are:

Compression springs offer numerous advantages that make them a popular choice in engineering:

Compression springs are truly everywhere! Here are just a few examples of their diverse applications:

While the basic principle of compression springs is the same, there are several types that differ in their design and intended use:

Selecting the appropriate compression spring for your specific needs depends on several factors:

Compression springs are just one member of a large and diverse family of springs. Other types include:

Each type of spring has its unique characteristics and advantages, making them suitable for different applications. Understanding the various types of springs available allows engineers to select the optimal one for their specific design needs.

In a world that relies heavily on motion and mechanics, compression springs play a critical role, quietly ensuring smooth operation and providing essential force. From the everyday items we use to the complex machinery that powers our world, compression springs are the unsung heroes of design, tirelessly performing their functions without fanfare. By understanding the intricacies of compression spring design and selecting the right type for the application, engineers can leverage these remarkable components to create innovative and reliable solutions.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.