Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

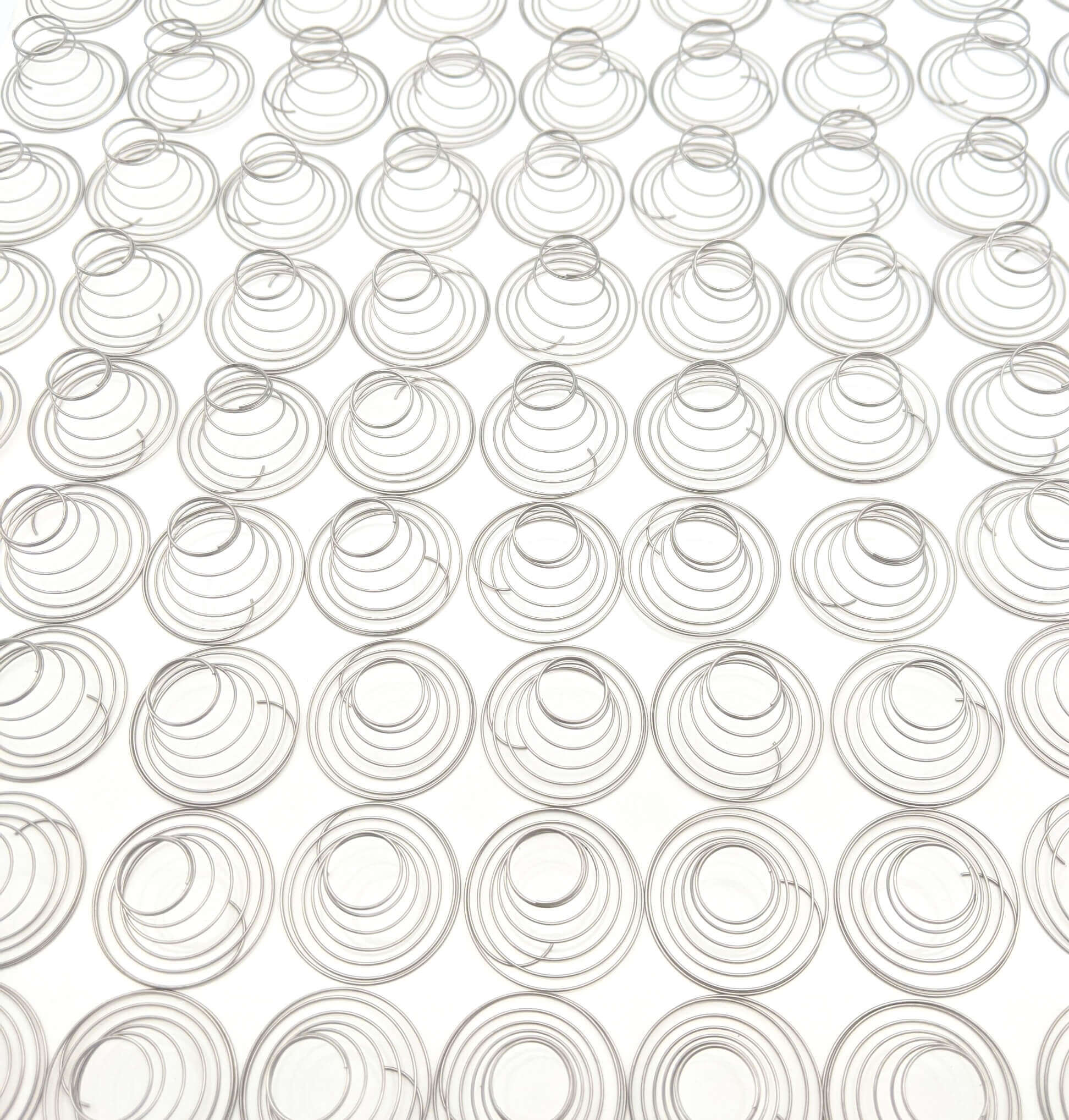

Compression springs, those ubiquitous coils of metal often found hidden within our everyday objects, are far more than just simple mechanical components. They are the unsung heroes of countless devices,

Compression springs, those ubiquitous coils of metal often found hidden within our everyday objects, are far more than just simple mechanical components. They are the unsung heroes of countless devices, from the humble ballpoint pen to the complex machinery that powers our world. Their ability to store and release energy, providing a force that pushes or resists, is what makes them indispensable in a wide array of applications. In this article, we delve into the fascinating world of compression springs, exploring their design, materials, applications, and the physics that govern their behavior.

Compression springs are designed to operate under a compressive load, meaning they shorten in length when a force is applied to them. Imagine a simple coil spring, like the one you might find in a pen or a toy. When you push down on it, the coils compress, and the spring stores energy. The more you push, the more energy is stored, and the stronger the force the spring will exert when released. This is a fundamental concept in understanding how compression springs work.

The force a compression spring exerts is directly proportional to its compression, a relationship known as Hooke's Law. This law states that the force (F) is equal to the spring constant (k) multiplied by the compression (x): F = kx. The spring constant (k) is a measure of the spring's stiffness. A higher spring constant indicates a stiffer spring, requiring more force to compress it a given distance. The spring constant depends on factors like the material, wire diameter, number of coils, and the spring's geometry.

The material chosen for a compression spring depends on the specific application and the required properties. Spring steel, a highly resilient and durable metal, is the most common material. However, other metals like stainless steel, phosphor bronze, and titanium are used for applications requiring corrosion resistance or specific electrical conductivity. The manufacturing process typically involves coiling a wire around a mandrel, creating a helical spring.

The shape and size of the spring are carefully controlled to achieve the desired performance characteristics. Factors such as the number of coils, the wire diameter, and the spring's end configuration all play a role in determining the spring's stiffness, its maximum load capacity, and its overall performance.

Compression springs are used in a remarkably wide range of applications, from the seemingly trivial to the critically important. Here are just a few examples:

Everyday Objects:

Industrial and Automotive:

Other Notable Applications:

Selecting the right compression spring for a particular application requires careful consideration of several factors:

Compression springs have been an essential part of our technological landscape for centuries. As technology continues to advance, the demand for smaller, lighter, and more efficient springs is increasing. Researchers are exploring new materials, such as shape memory alloys, and innovative manufacturing techniques to create springs with enhanced performance characteristics. Additionally, the development of smart materials and sensors is opening up new possibilities for compression springs that can adapt to changing conditions and provide feedback on their own performance.

In conclusion, compression springs are not just ordinary mechanical components; they are vital elements in a vast array of technological marvels. Their ability to store and release energy, providing a force that pushes or resists, is what makes them so versatile and essential. From the smallest everyday objects to the most complex machinery, compression springs continue to play a crucial role in shaping our world. As technology continues to evolve, we can expect to see even more innovative applications of these unsung heroes of engineering.

Compression springs are often unseen, yet they silently work tirelessly to make our lives easier and our world more functional. As we continue to push the boundaries of technology, compression springs are likely to play an even greater role in the future, showcasing their resilience and adaptability in new and exciting ways.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.