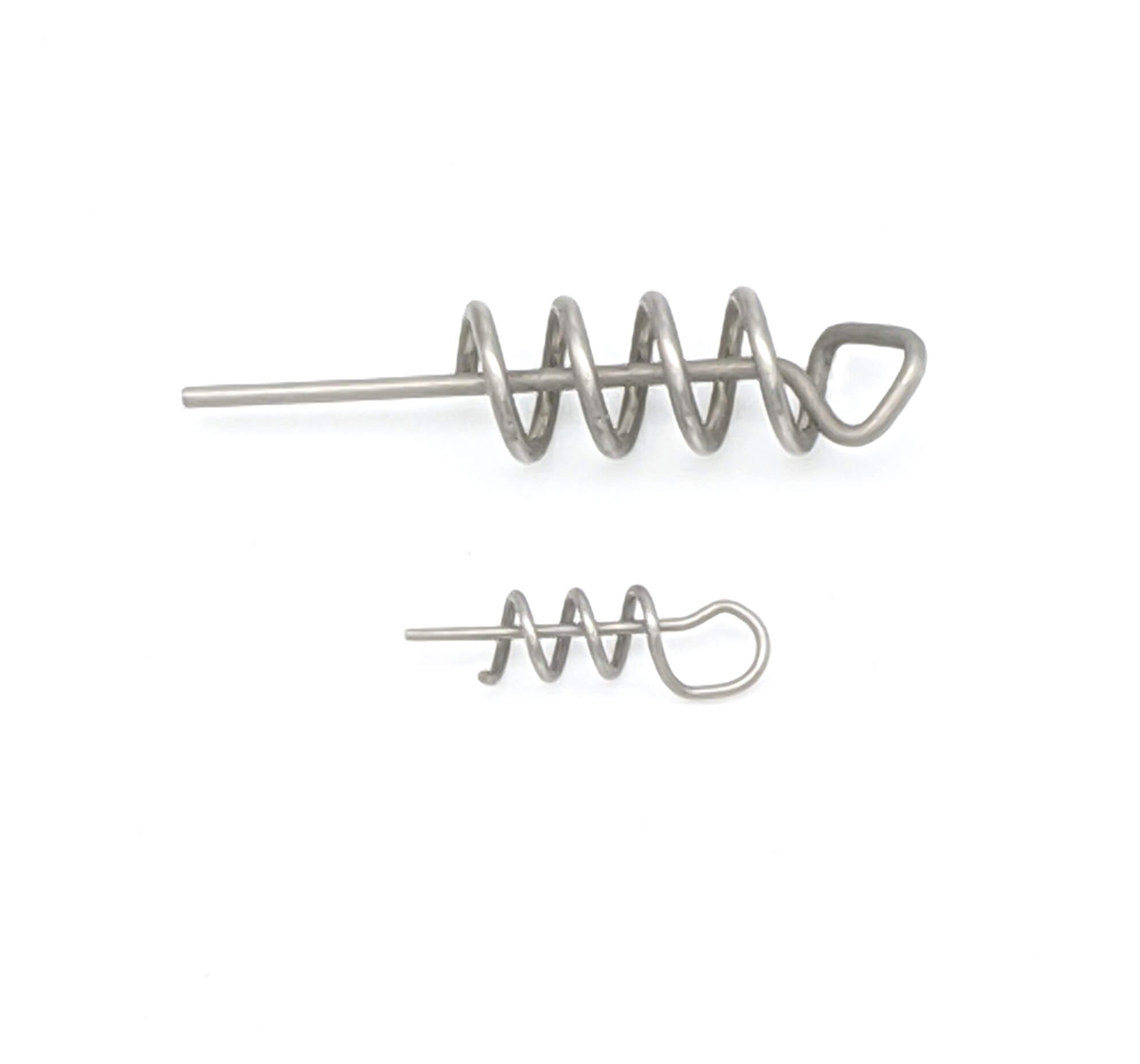

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, those humble coils of metal that we often take for granted, play a vital role in countless everyday objects and systems. From the simple act of opening a

Compression springs, those humble coils of metal that we often take for granted, play a vital role in countless everyday objects and systems. From the simple act of opening a door to the complex workings of a car engine, compression springs provide the force and resilience that make our lives smoother and more efficient. Let's delve into the fascinating world of compression springs, exploring their fundamental principles, diverse applications, and the innovative ways they are continuously evolving to meet the demands of modern engineering.

At their core, compression springs are designed to resist compressive forces, meaning they shorten in length when a load is applied. Imagine a simple coil spring like those found in a child's toy. When you push down on it, the spring compresses, storing potential energy. The more you push, the more the spring compresses, and the more energy it stores. This stored energy is then released when the force is removed, causing the spring to return to its original length. This fundamental principle is at the heart of countless mechanical applications.

The behavior of compression springs is governed by a fundamental principle in physics known as Hooke's Law. This law states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. In simpler terms, the more you compress a spring, the greater the force it pushes back with. This relationship is described by the equation: F = -kx, where F is the force, k is the spring constant (a measure of the spring's stiffness), and x is the displacement.

Compression springs are typically made of coiled wire, often from hardened steel, although other materials such as brass, bronze, or stainless steel are used for specific applications. The key features that determine a compression spring's behavior include:

Compression springs are ubiquitous, finding their way into a wide range of applications across various industries. Here are some examples that highlight their versatility:

While traditional compression springs have served us well for centuries, engineers are constantly seeking new and innovative ways to improve their performance and expand their applications. Here are some key innovations in compression spring technology:

Selecting the right compression spring for a specific application requires careful consideration of several factors, including:

The field of compression spring technology is continually evolving, driven by advances in materials science, manufacturing techniques, and design software. We can expect to see even more innovative compression springs emerge in the future, pushing the boundaries of performance and finding new applications in fields like robotics, energy harvesting, and biomechanics. From the smallest gadgets to the largest machines, compression springs continue to play a vital role in our technological world, making it a smoother and more efficient place.

Compression springs, though often unseen, are crucial components in countless everyday applications. Their ability to store and release energy, resist compressive forces, and adapt to diverse needs make them indispensable in engineering, manufacturing, and our daily lives. As technology continues to evolve, we can expect compression springs to become even more versatile, finding new ways to enhance our world and push the boundaries of what's possible.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.