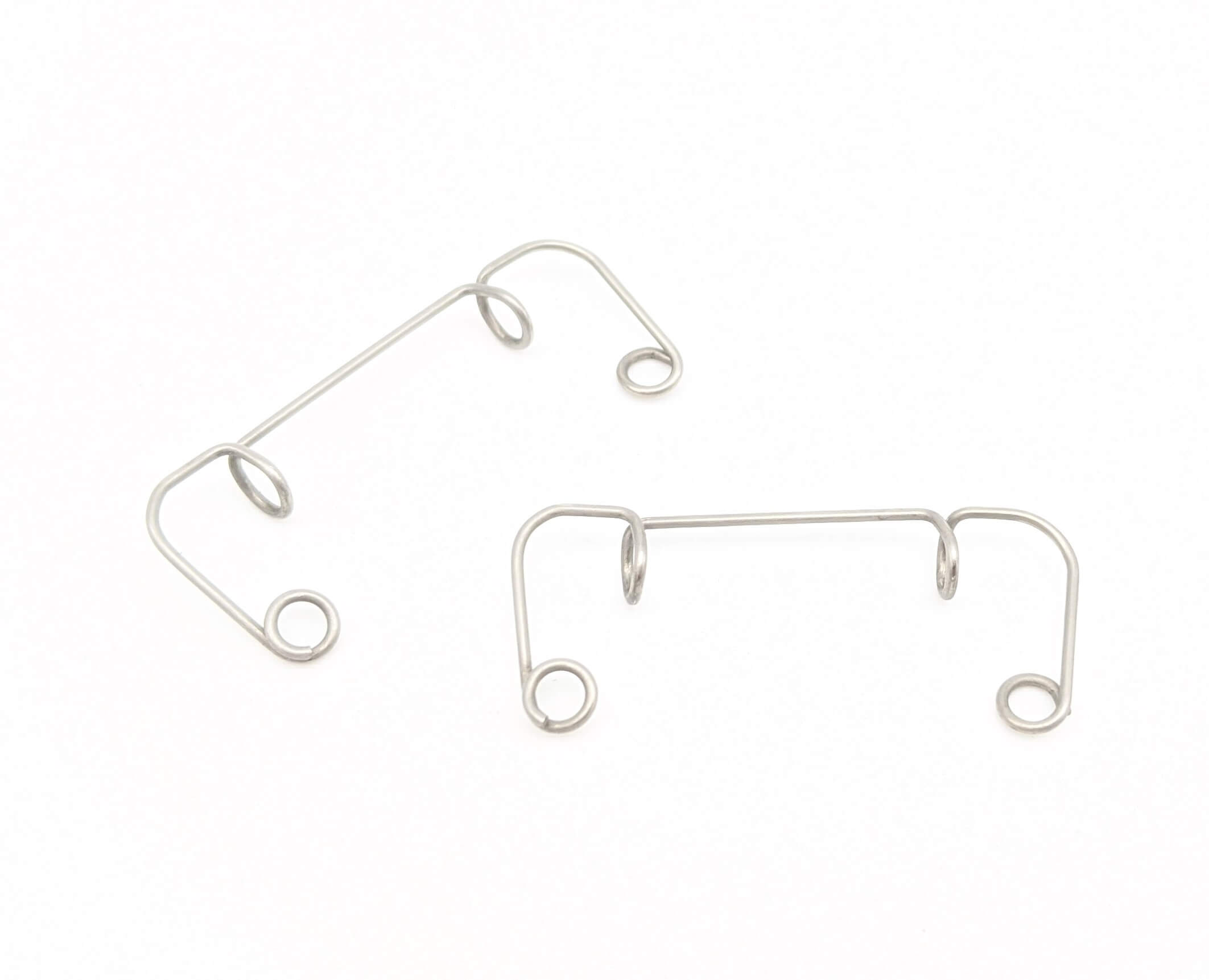

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, those ubiquitous coils of metal, play a vital role in countless devices and systems around us. From the simple act of opening a door to the complex workings

Compression springs, those ubiquitous coils of metal, play a vital role in countless devices and systems around us. From the simple act of opening a door to the complex workings of a car engine, compression springs provide essential functionality. Their ability to absorb and store energy, offering resistance to compression, makes them indispensable in countless applications. But what exactly are compression springs, how do they work, and why are they so important? Let's delve into the fascinating world of compression springs and uncover their hidden power.

In essence, a compression spring is a helical coil of wire designed to resist compression. When a force is applied to compress the spring, it stores energy and pushes back with an opposing force. This force is proportional to the amount of compression, a principle known as Hooke's Law. The spring's resistance to compression is measured by its spring constant, a value that indicates how much force is needed to compress the spring by a certain distance.

The secret behind a compression spring's functionality lies in its material properties and design. They are typically made of spring steel, a highly elastic material that can withstand repeated compression and release without deforming. The wire used for the spring is coiled into a helical shape, creating a series of loops. These loops are designed to be close enough together that they touch or nearly touch in the uncompressed state, but with enough space between them to allow for compression.

When a force is applied to the spring, the loops are pushed closer together, compressing the spring. The spring resists this compression, pushing back with a force proportional to the amount of compression. When the force is removed, the spring returns to its original shape, releasing the stored energy.

Compression springs are characterized by several key features that determine their performance and suitability for specific applications:

While the basic principle of operation remains the same, compression springs come in various shapes, sizes, and designs, each tailored for specific applications. Some common types include:

Compression springs are widely used in countless industries and applications, playing a vital role in everything from simple mechanical devices to sophisticated machinery. Some notable examples include:

Compression springs offer several key advantages that make them the preferred choice for many applications:

While compression springs offer numerous advantages, they also present some challenges and considerations that should be carefully addressed:

Compression springs, though seemingly simple, are essential components in countless applications, providing force, energy storage, and shock absorption. Understanding their characteristics, types, and applications is crucial for designing and implementing reliable systems. Whether you're an engineer working on complex machinery or a hobbyist building a simple device, a thorough grasp of compression spring principles will empower you to create innovative and functional solutions.

So, the next time you encounter a compression spring, take a moment to appreciate its hidden power and the countless ways it contributes to our everyday lives. From the gentle push of a door handle to the powerful force behind a car engine, compression springs play a vital role in shaping our world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.