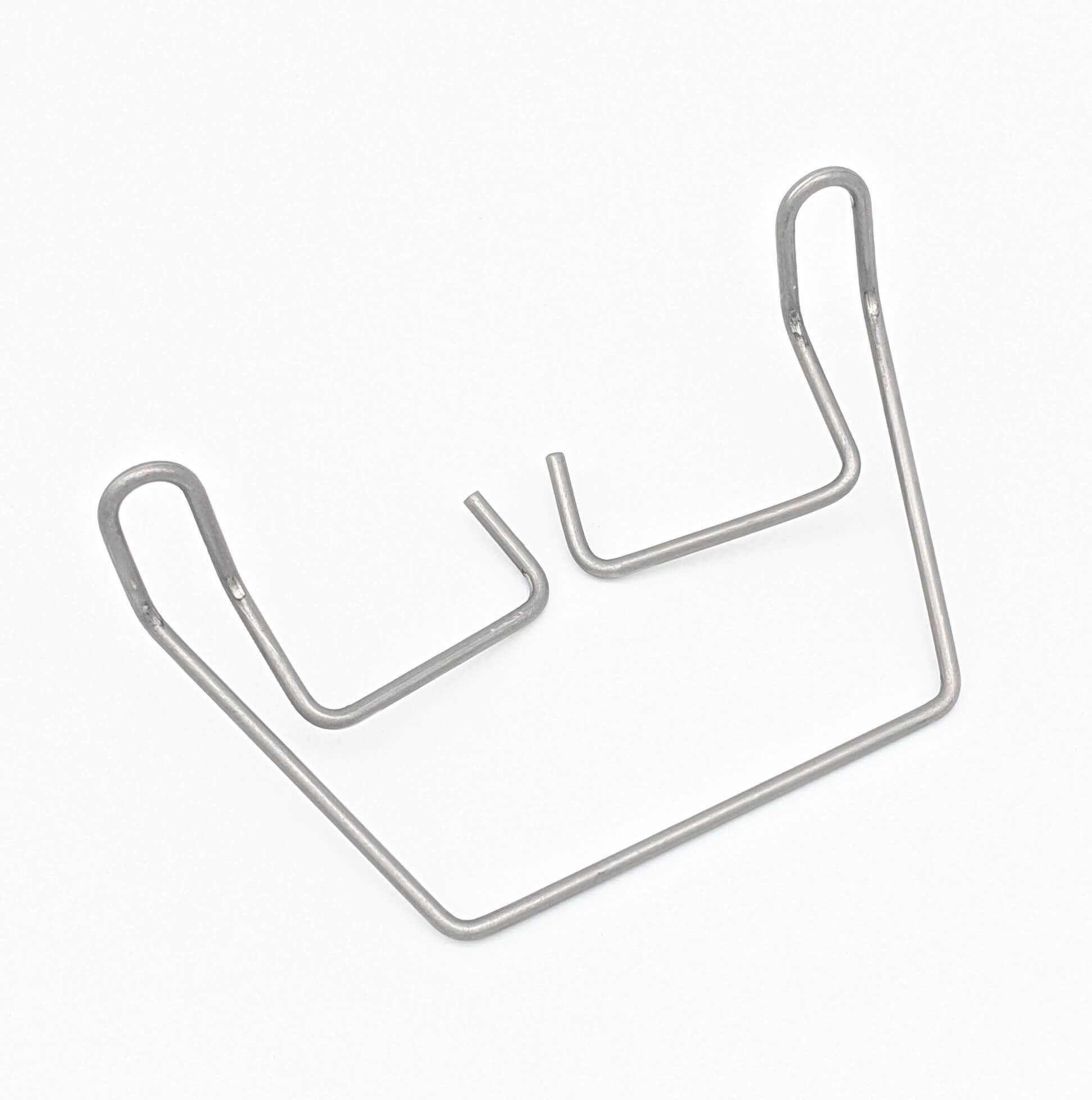

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, those ubiquitous coils of metal that store energy and provide resistance, are found in countless applications, from everyday objects to complex machinery. When made from stainless steel, these

Compression springs, those ubiquitous coils of metal that store energy and provide resistance, are found in countless applications, from everyday objects to complex machinery. When made from stainless steel, these springs offer a unique combination of strength, durability, and resistance to corrosion, making them ideal for demanding environments. This article delves into the world of compression springs, exploring their construction, properties, and applications, with a particular focus on the advantages of stainless steel in these essential components.

Compression springs, as their name suggests, are designed to resist compression forces. They are typically formed by coiling a wire of specific material around a mandrel, creating a helical shape. When a load is applied to a compression spring, it compresses, storing energy within its coils. Once the load is removed, the spring returns to its original length, releasing the stored energy. This fundamental principle makes compression springs essential components in various applications, from simple mechanical devices to sophisticated machinery.

The choice of material for a compression spring is crucial for its performance and longevity. While various metals are used, stainless steel stands out for its exceptional properties.

Stainless steel compression springs offer a compelling set of advantages that make them ideal for a wide range of applications. Here's why stainless steel reigns supreme:

Stainless steel, known for its high tensile strength, is capable of withstanding significant forces without permanent deformation. This inherent strength ensures that compression springs made from stainless steel can reliably handle heavy loads and repeated cycles of compression and extension, making them incredibly durable and long-lasting.

Stainless steel springs are particularly valuable in environments where corrosion is a concern. Their inherent resistance to rust and oxidation allows them to maintain their structural integrity and functionality even when exposed to harsh conditions, such as moisture, chemicals, and extreme temperatures. This resilience ensures that stainless steel springs perform consistently over time, even in challenging environments.

Stainless steel comes in various grades, each possessing unique properties tailored to different applications. For compression springs, common grades include:

By selecting the appropriate stainless steel grade, engineers can tailor compression springs to meet the specific requirements of their application.

Stainless steel exhibits exceptional resistance to fatigue and wear, even under repeated compression cycles. This resistance ensures that stainless steel compression springs maintain their performance and spring rate over time, reducing the need for frequent replacements. They are particularly advantageous in applications where springs are subjected to continuous cyclic loading, such as automotive suspension systems or industrial machinery.

Stainless steel compression springs can withstand a wide range of temperatures without compromising their strength or functionality. They maintain their properties at both high and low temperatures, making them suitable for applications exposed to extreme thermal environments, such as high-temperature furnaces or cryogenic systems.

Certain stainless steel grades, particularly those with low levels of nickel and chromium, are biocompatible, meaning they are safe for use in medical devices and implants. This biocompatibility makes them suitable for applications where contact with living tissue is required, such as surgical instruments, prosthetic implants, and medical equipment.

The exceptional properties of stainless steel compression springs have led to their widespread use across various industries, including:

Stainless steel compression springs are essential in automotive suspension systems, providing shock absorption and ride comfort. They are also used in engine components, brake systems, and seat mechanisms, ensuring reliability and durability in demanding environments.

The strength, corrosion resistance, and temperature resistance of stainless steel springs make them crucial components in aerospace applications, including landing gear, control systems, and satellite mechanisms.

In industrial settings, stainless steel compression springs are employed in a multitude of machinery, including pumps, compressors, conveyors, and automated systems. Their durability and reliability ensure smooth operation and extended service life in harsh industrial environments.

Biocompatible stainless steel springs play a vital role in medical devices and implants, such as surgical instruments, orthopedic implants, and prosthetic devices. Their resistance to corrosion and biocompatibility ensure safety and longevity in these critical applications.

Stainless steel compression springs are found in numerous consumer products, from household appliances like washing machines and refrigerators to sporting goods like bicycles and golf clubs. Their durability and performance contribute to the reliability and longevity of these products.

Stainless steel compression springs offer a compelling combination of strength, corrosion resistance, durability, and temperature resistance, making them ideal for a wide range of applications. Their unique properties ensure reliability, longevity, and consistent performance, even in demanding environments. Whether in automotive systems, aerospace components, industrial machinery, medical devices, or consumer products, stainless steel compression springs are the unsung heroes, providing the resilient support and functionality necessary for countless modern marvels.

By understanding the advantages of stainless steel compression springs and their diverse applications, engineers and designers can confidently select these robust components to enhance the reliability and performance of their creations. Whether in demanding industrial environments or critical medical applications, stainless steel compression springs continue to play a vital role in our modern world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.