Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the intricate world of engineering and design, compression springs are unsung heroes. These coiled wonders, often made from stainless steel, are ubiquitous in countless applications, ensuring smooth operation and

In the intricate world of engineering and design, compression springs are unsung heroes. These coiled wonders, often made from stainless steel, are ubiquitous in countless applications, ensuring smooth operation and reliability. From the gentle push of a refrigerator door to the powerful force driving a car suspension, compression springs are essential for a myriad of functions. This article delves into the fascinating world of compression springs, exploring their construction, properties, and diverse applications, particularly focusing on those made from the robust and corrosion-resistant material, stainless steel.

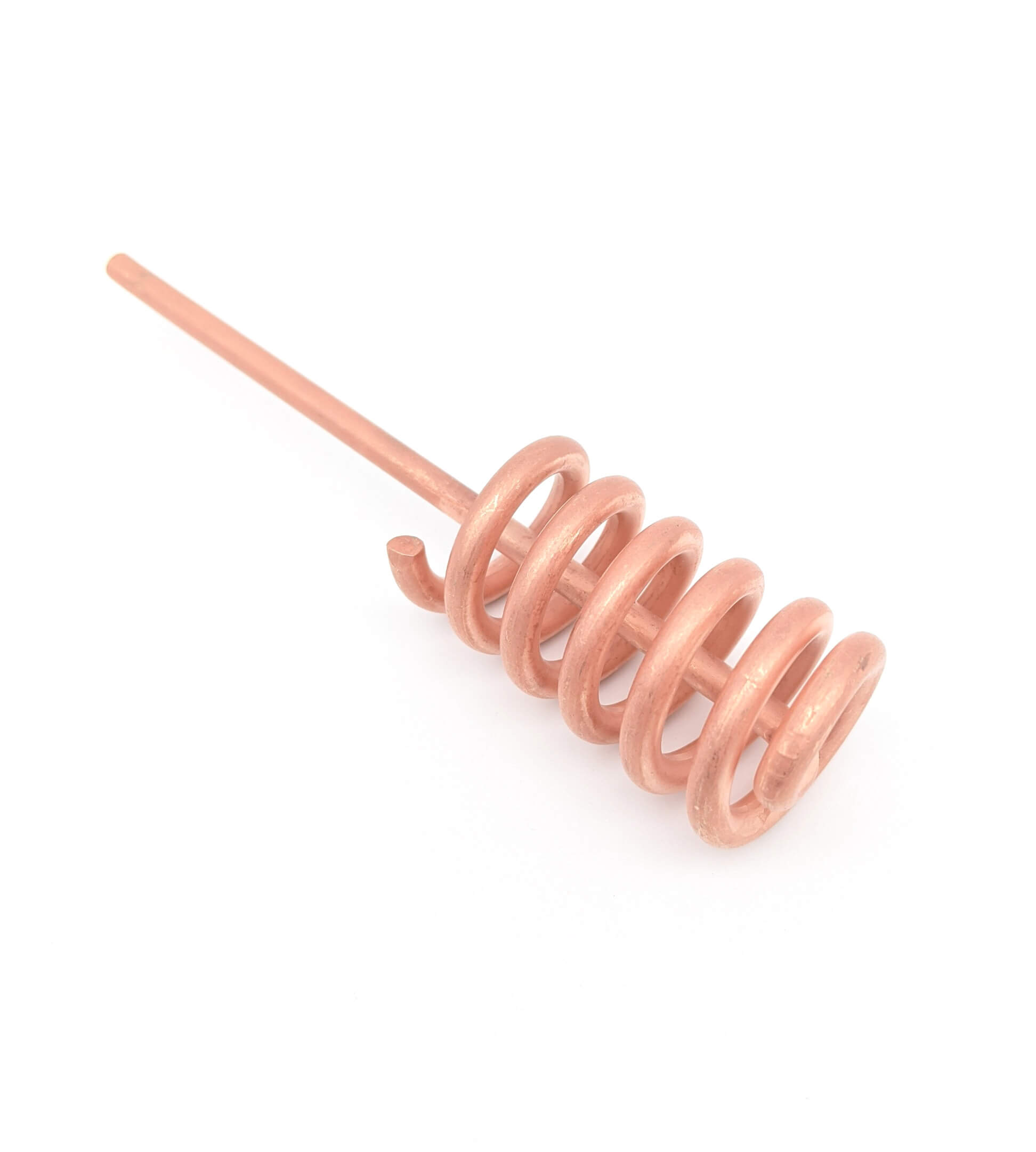

Compression springs, as their name suggests, are designed to resist compressive forces. They are essentially coils of wire, meticulously wound to store mechanical energy and release it when needed. When a compressive force is applied, the spring compresses, storing energy, and upon release, it returns to its original shape, pushing back with a counteracting force.

Stainless steel, with its inherent resistance to corrosion and exceptional strength, is often the preferred material for compression springs. This alloy, comprising primarily iron, chromium, and sometimes other elements like nickel and molybdenum, exhibits remarkable durability and resilience, making it suitable for a wide range of applications. Its corrosion resistance ensures that the springs maintain their integrity and performance even in challenging environments, like those exposed to moisture, chemicals, or extreme temperatures. Furthermore, stainless steel's inherent strength allows for the creation of compact and powerful compression springs capable of handling significant loads.

The world of stainless steel compression springs is vast and diverse. These springs play critical roles in numerous industries, contributing to the seamless operation of countless devices and machines. Some prominent applications include:

Stainless steel compression springs offer a multitude of benefits that make them highly desirable for various applications:

Selecting the appropriate stainless steel compression spring for a particular application involves considering several factors:

Stainless steel compression springs are indispensable components in countless applications, ranging from simple consumer products to sophisticated industrial machinery. Their exceptional corrosion resistance, strength, durability, and versatility make them the preferred choice for a wide range of engineering challenges. Understanding the various properties and applications of compression springs is crucial for selecting the most suitable option, ensuring optimal performance and longevity.

The next time you encounter a compression spring, take a moment to appreciate its subtle but powerful role. From the gentle push of a refrigerator door to the robust force driving a car suspension, these unassuming coils of stainless steel are the unsung heroes of our modern world, silently working to ensure smooth operation and reliability in countless applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.