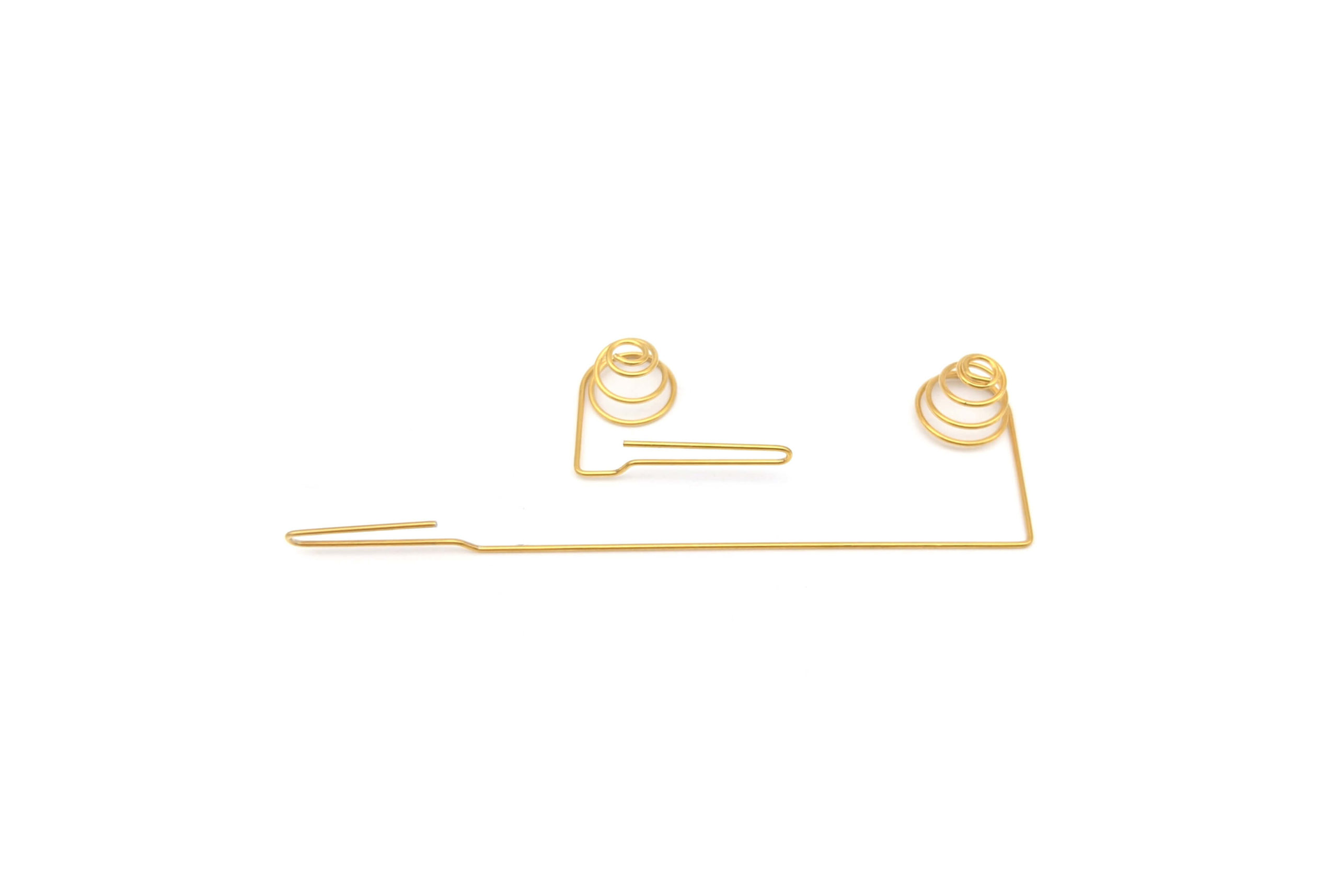

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, ubiquitous yet often unseen, are the silent workhorses of countless mechanical systems. From the simple act of pushing a button to the complex workings of a car suspension,

Compression springs, ubiquitous yet often unseen, are the silent workhorses of countless mechanical systems. From the simple act of pushing a button to the complex workings of a car suspension, these coiled marvels of engineering silently absorb and release energy, ensuring smooth and efficient operation. But beyond their widespread use, compression springs offer a fascinating story of design, material science, and the triumph of simple yet powerful principles.

Imagine a world without compression springs. Your car wouldn't bounce back after hitting a bump, your pen wouldn't retract, and even your mattress wouldn't offer that comforting springiness. That's the power of these seemingly simple devices, their presence often taken for granted yet their absence leaving a noticeable void.

At their core, compression springs are coiled wires designed to absorb energy when compressed, storing it like a tiny, coiled reservoir of potential energy. This stored energy is then released as the spring returns to its original shape, providing a force that powers countless mechanical actions.

The beauty of compression springs lies in their versatility. They come in an array of shapes, sizes, and materials, each tailored to specific applications. From the delicate springs in a wristwatch to the robust springs in a heavy-duty industrial machine, each spring is a testament to the precision and artistry of mechanical design.

A compression spring's ability to store and release energy is rooted in Hooke's Law, a fundamental principle of physics. This law states that the force a spring exerts is directly proportional to its deformation. In simpler terms, the more you compress a spring, the greater the force it will exert when released. This force, known as the spring rate, is a crucial parameter in spring design, determining how much energy the spring can store and how much force it will generate.

The spring rate is influenced by a number of factors, including the material the spring is made from, its wire diameter, the number of coils, and the coil's diameter. Choosing the right material is critical; spring steel, with its excellent resilience and fatigue resistance, is often the go-to material for these applications. However, for applications demanding corrosion resistance, materials like phosphor bronze or titanium may be chosen.

Compression springs are truly ubiquitous, their applications touching virtually every aspect of modern life. Here are a few examples that showcase their versatility:

Automotive Industry: From suspension systems that absorb the impact of bumps to clutch springs that engage and disengage the transmission, compression springs play a vital role in car mechanics. They ensure smooth ride comfort, efficient gear shifting, and overall vehicle performance.

Electronics and Appliances: The tiny springs holding the keys on your keyboard, the spring-loaded mechanisms in your retractable pen, and the shock-absorbing springs in your phone case, all rely on the power of compression springs. They are essential for smooth operation and durability in a wide range of electronic devices and appliances.

Industrial Machinery: Heavy-duty industrial equipment, such as presses, conveyors, and lifting mechanisms, often employ compression springs to absorb shock loads, provide counterbalance, and ensure smooth operation. These springs must withstand extreme forces and wear, making them vital components in industrial processes.

Medical Devices: The healthcare industry, especially in medical devices, relies heavily on compression springs. They are used in medical instruments, such as surgical forceps, retractors, and other tools that require precise force application and control.

Home and Furniture: From the springs in your sofa and mattress that provide cushioning and comfort to the springs in your garage door opener that ensure smooth opening and closing, these silent workhorses are an integral part of our everyday lives.

Designing a compression spring is not simply a matter of choosing a coil and calling it a day. It's a meticulous process involving careful consideration of several key factors, including:

Load Requirements: What is the maximum load the spring needs to withstand? This determines the spring's wire diameter, the number of coils, and the material choice.

Deflection Limits: How much compression or extension is required? This factor is crucial for ensuring the spring operates within its design parameters, preventing overstretching or overcompression.

Operating Environment: Will the spring be exposed to extreme temperatures, corrosive substances, or other harsh conditions? These factors dictate the material selection and surface treatment, ensuring the spring's longevity and reliability.

Durability and Fatigue Resistance: How many cycles of compression and release will the spring endure? This consideration is critical for springs subjected to repeated loading, ensuring they don't fatigue or fail prematurely.

The story of compression springs is intertwined with the history of mechanical engineering itself. Their invention revolutionized how we interact with the world, paving the way for countless innovations. The humble compression spring is a testament to the power of simple yet elegant design principles, demonstrating how a seemingly simple device can have profound impacts on our lives.

From the early days of clockwork mechanisms to the complex systems of modern machinery, compression springs have consistently driven progress. Their ability to store and release energy, their resilience under stress, and their adaptability to various applications make them invaluable components in countless systems. They are the silent heroes of modern mechanics, ensuring the smooth operation of our world, one compression cycle at a time.

As we continue to push the boundaries of engineering, compression springs will undoubtedly continue to play a vital role. They are not simply coiled wires; they are miniature energy reservoirs, force multipliers, and essential components that underpin countless technological marvels. So the next time you press a button, open a door, or enjoy a comfortable ride, remember the silent workhorses of mechanics, the unsung heroes of countless innovations, the compression springs that make our world a little smoother, a little more efficient, and a little more comfortable.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.