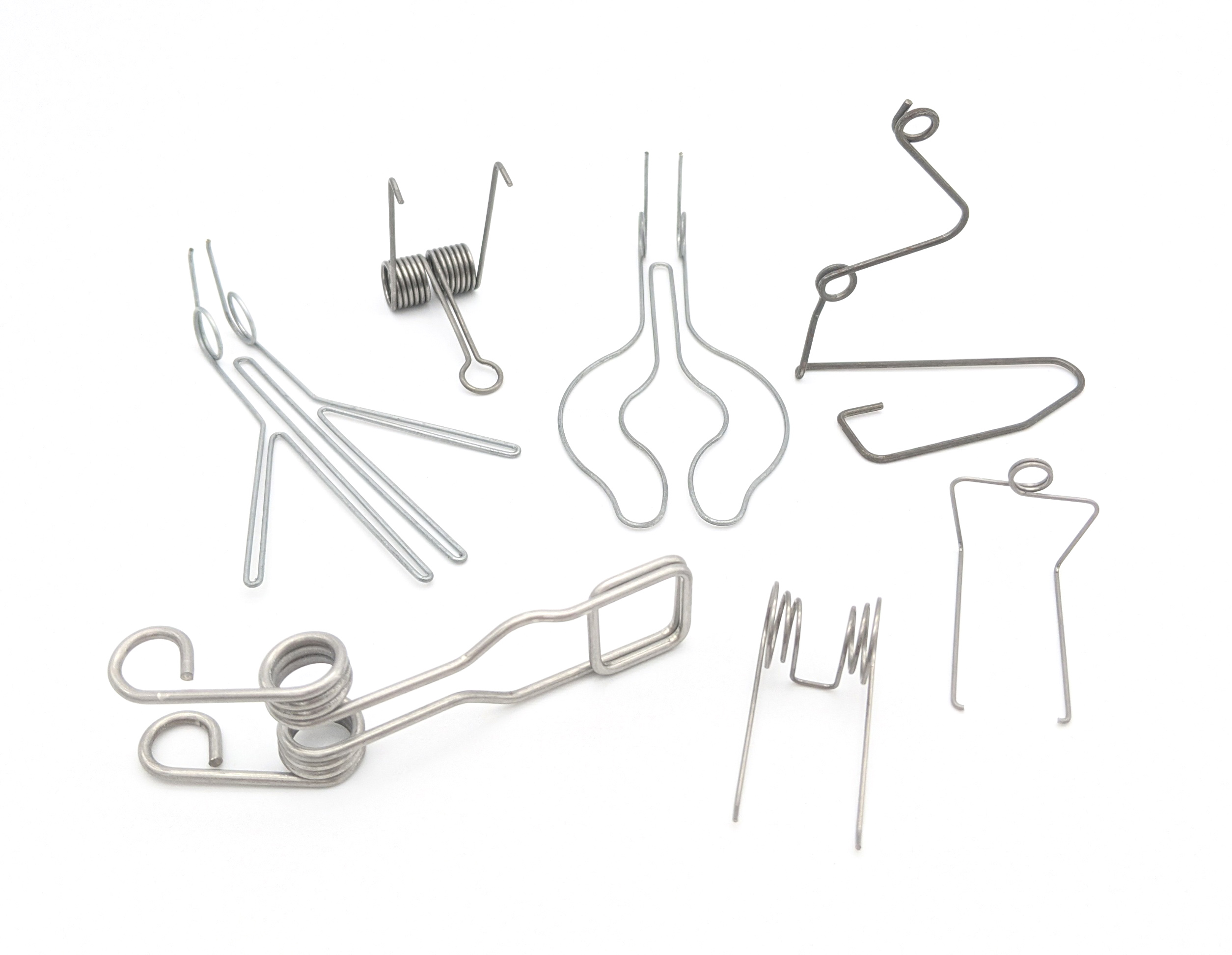

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs are ubiquitous in our world, silently working behind the scenes to provide essential functionality in countless applications. From the simple act of closing a door to the intricate

Compression springs are ubiquitous in our world, silently working behind the scenes to provide essential functionality in countless applications. From the simple act of closing a door to the intricate workings of a car engine, compression springs play a crucial role in ensuring smooth, reliable operation. They are marvels of engineering, storing and releasing energy with remarkable efficiency. In this comprehensive guide, we delve into the fascinating world of compression springs, exploring their design, properties, types, applications, and the science behind their remarkable performance.

Compression springs are helical springs designed to absorb energy when compressed, storing it as potential energy and releasing it when the load is removed. They are essentially coiled lengths of wire, usually made of spring steel, which are designed to shorten when subjected to an axial force. The coiled shape of the spring allows it to efficiently store and release energy, making it an indispensable component in a vast array of mechanical systems.

The behavior of compression springs is governed by Hooke's law, which states that the force exerted by a spring is directly proportional to its deformation. In simpler terms, the more you compress a spring, the greater the force it will exert back. This linear relationship makes compression springs incredibly predictable and reliable, allowing engineers to design systems with precise control over motion and energy storage.

Compression springs come in a variety of types, each with its own unique characteristics and applications. Some common types include:

Compression springs find applications in virtually every industry, from automotive and aerospace to consumer products and medical devices. Here are some notable examples:

Compression springs offer numerous advantages that make them indispensable in various applications:

Selecting the appropriate compression spring for a given application is crucial for optimal performance and reliability. Here are some key factors to consider:

Compression springs are essential components in countless mechanical systems, silently working to ensure smooth and reliable operation. Their ability to store and release energy with precision makes them indispensable in a wide range of applications. By understanding the principles of compression spring design and selection, engineers can harness their power to create innovative solutions that enhance the functionality and efficiency of various systems.

Compression springs are often the unsung heroes of our technological world, quietly but effectively performing their tasks in countless applications. Whether it's a simple spring-loaded door latch or a critical component in a complex industrial machine, compression springs play a vital role in our lives. As we move forward in a world driven by technology, the importance of compression springs will only continue to grow, ensuring the smooth and efficient operation of the systems that shape our future.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.