Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, those ubiquitous coils of metal that store and release mechanical energy, are an essential component in countless machines and devices. From the simple act of opening a ballpoint

Compression springs, those ubiquitous coils of metal that store and release mechanical energy, are an essential component in countless machines and devices. From the simple act of opening a ballpoint pen to the complex operation of a car engine, compression springs play a vital role in our daily lives. They are designed to resist compression forces, storing potential energy that can be released to perform work. This article will delve into the fascinating world of compression springs, exploring their design principles, functionalities, and diverse applications.

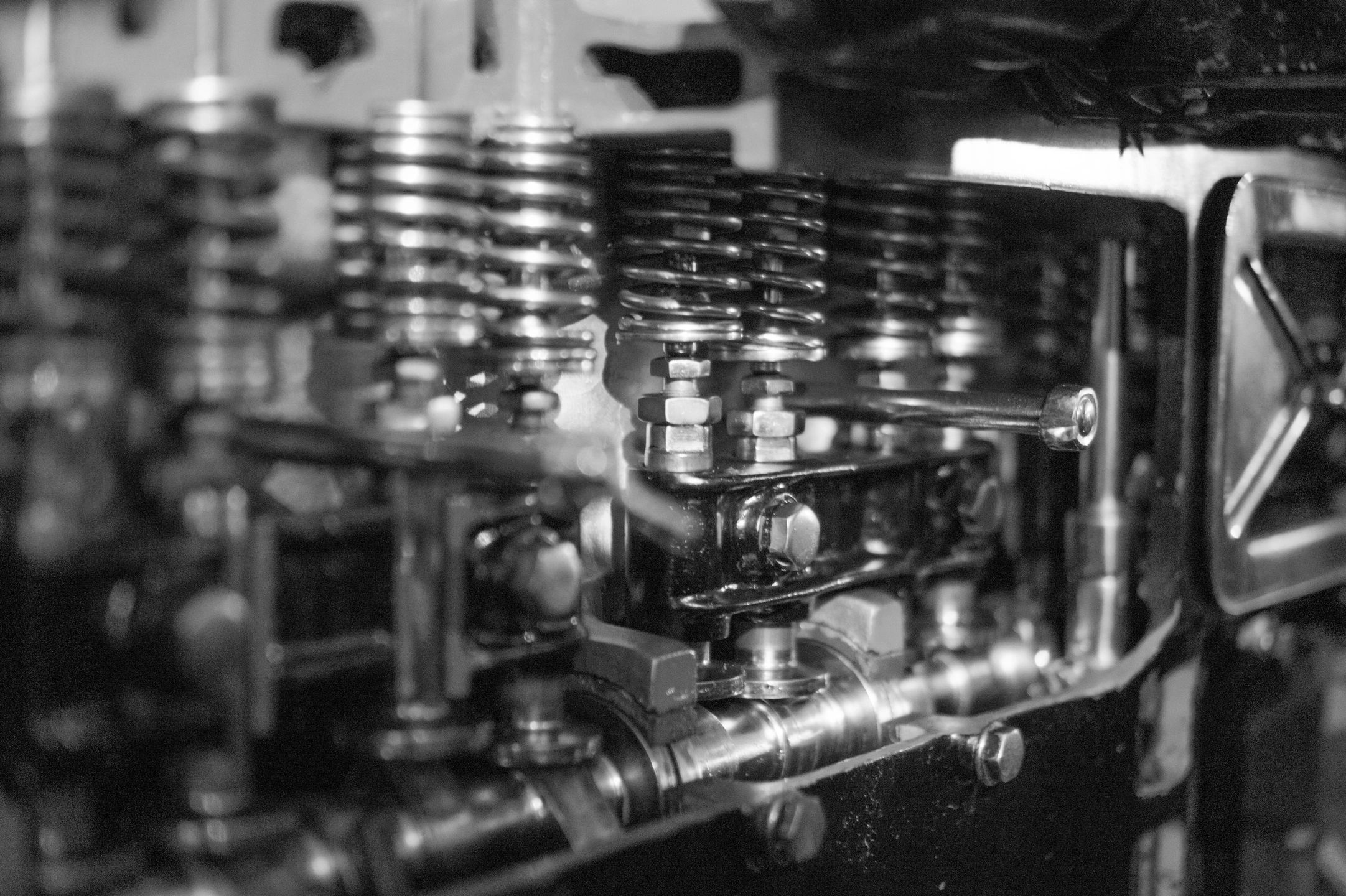

At their core, compression springs are helical coils of wire, typically made from steel or other resilient materials. When a force is applied to a compression spring, it compresses, storing energy within its coils. The spring's ability to store energy is directly related to its spring rate, which quantifies the force required to compress the spring by a specific distance. This characteristic makes compression springs ideal for various applications where controlled energy storage and release are crucial.

The design of a compression spring is critical to its performance. Factors such as the wire diameter, coil diameter, number of coils, and spring material all influence the spring's spring rate, load capacity, and fatigue resistance. Engineers meticulously select these parameters to ensure the spring operates within its desired range and meets the specific demands of the application.

The force required to compress a compression spring is directly proportional to the spring's spring rate and the compression distance. This relationship can be expressed mathematically using Hooke's Law, a fundamental principle in spring mechanics. The equation, F = kx, where F is the force, k is the spring rate, and x is the compression distance, beautifully captures the interplay between these factors.

Understanding this principle allows engineers to precisely calculate the forces and displacements within a spring-based system, ensuring optimal performance and safety. The spring rate, often expressed in units of force per unit length, determines the spring's stiffness. A higher spring rate indicates a stiffer spring that requires more force to compress. Conversely, a lower spring rate corresponds to a softer spring that is easier to compress.

Compression springs find applications across numerous industries, contributing to the functionality of a wide array of products and systems. Here are some noteworthy examples:

**Automotive:** From suspension systems to engine valves, compression springs are essential components in automobiles. They absorb shocks, regulate engine timing, and provide a smooth ride.

**Industrial Machinery:** In manufacturing, compression springs are used in countless machines, powering actuators, clamping components, and providing tension for belts and chains. Their ability to withstand high loads and cyclic stresses makes them ideal for demanding industrial environments.

**Electronics:** Miniature compression springs are vital in electronic devices, providing pressure for button contacts, securing connectors, and holding components in place.

**Consumer Products:** From ballpoint pens to retractable pens and spring-loaded doors, compression springs enhance the usability and functionality of everyday items.

**Medical Devices:** Compression springs are integrated into medical devices such as syringes, surgical tools, and medical implants, contributing to their precision and functionality.

Compression springs offer numerous advantages over other mechanical solutions, making them a preferred choice in countless applications.

**Simplicity and Versatility:** Their basic design and ease of manufacturing allow for versatile applications across various industries.

**Energy Efficiency:** Compression springs efficiently store and release mechanical energy, minimizing energy loss and enhancing system performance.

**Reliability:** When properly designed and manufactured, compression springs offer exceptional durability and reliability, capable of withstanding millions of cycles without degradation.

**Cost-effectiveness:** Compression springs are generally cost-effective solutions, especially in mass-produced products.

Selecting the appropriate compression spring is crucial for optimal performance and longevity. Factors such as the required spring rate, load capacity, operating environment, and material properties must be carefully considered.

Consult with a spring manufacturing specialist to determine the best design and materials for your specific application. Experienced engineers can provide expert advice and ensure that the chosen spring meets the required specifications and performs reliably under the intended operating conditions.

Compression springs are more than just coiled pieces of metal; they are ingenious mechanical devices that underpin countless technological advancements. Their ability to store and release energy efficiently and reliably has revolutionized our world, enabling the creation of everything from simple everyday objects to complex machines. As technology continues to advance, we can expect compression springs to play an even more prominent role, driving innovation and shaping the future.

The world of compression springs is vast and fascinating. By understanding their design, function, and applications, we gain a deeper appreciation for these ubiquitous components and their essential role in modern technology. Whether you are a budding engineer, a curious consumer, or simply someone interested in the mechanics of our world, the story of compression springs is sure to captivate your imagination and inspire you to explore further.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.