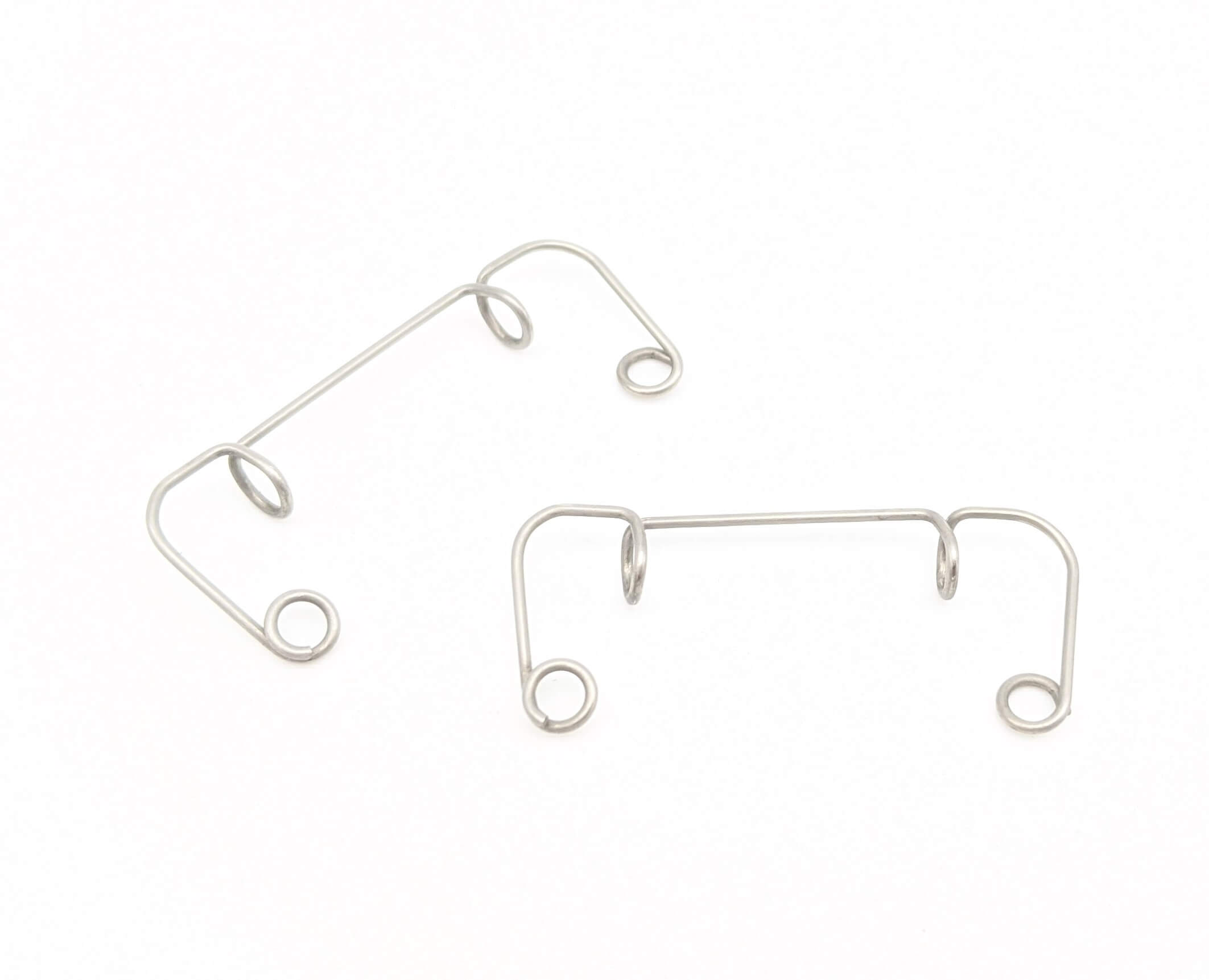

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, the ubiquitous coiled marvels of engineering, are found in countless applications, from everyday objects like pens and car seats to complex machinery and aerospace components. Their ability to

Compression springs, the ubiquitous coiled marvels of engineering, are found in countless applications, from everyday objects like pens and car seats to complex machinery and aerospace components. Their ability to store and release energy through compression makes them indispensable for various functions, ranging from providing support and cushioning to creating tension and controlling motion. This article delves into the intricacies of compression springs, exploring their design principles, materials, manufacturing processes, and diverse applications. We'll uncover how these seemingly simple devices play a crucial role in shaping the world around us.

Compression springs, as their name suggests, are designed to resist compression forces. They are essentially helical coils of wire, typically made from spring steel, that are wound tightly together. When a force is applied to a compression spring, it compresses, storing potential energy. Upon release, the spring expands back to its original shape, releasing the stored energy. This ability to store and release energy is the foundation of compression springs' wide range of applications.

Compression springs consist of several key components that influence their behavior and performance:

The spring rate, also known as the spring constant (k), is a critical property that describes the spring's stiffness. It represents the amount of force required to compress the spring by a specific distance. The spring rate is measured in units of force per unit distance, such as pounds per inch (lb/in) or newtons per meter (N/m).

A higher spring rate indicates a stiffer spring, meaning it requires more force to compress it. Conversely, a lower spring rate corresponds to a softer spring, which can be compressed more easily.

The choice of material for compression springs is crucial for their performance, durability, and reliability. The most common material used is spring steel, due to its excellent combination of strength, elasticity, and fatigue resistance. Spring steel comes in various grades, each with different properties, offering a wide range of options for different applications. Other materials used for compression springs include:

Compression springs are manufactured using various methods, depending on the spring's size, shape, and desired properties. Common manufacturing processes include:

Compression springs are ubiquitous, finding applications in a vast array of industries and products. Some common examples include:

Compression springs offer several advantages that contribute to their widespread use:

Designing compression springs involves several factors that influence their performance and reliability. These considerations include:

To ensure the quality and reliability of compression springs, they undergo rigorous testing and quality control measures. These tests may include:

Compression springs are seemingly simple devices, but their impact on modern engineering is profound. Their ability to store and release energy, coupled with their versatility and cost-effectiveness, makes them indispensable for a wide range of applications. Understanding their design, materials, manufacturing processes, and applications is essential for anyone involved in engineering, product development, or design. Compression springs continue to play a crucial role in shaping the world around us, driving innovation and improving the functionality of countless products.

The next time you encounter a pen that smoothly retracts, a car seat that comfortably cushions your weight, or a machine that operates with precision, remember the unseen force behind it – the compression spring. These coiled marvels are a testament to the power of simplicity and ingenuity, silently working to make our lives easier and more efficient.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.