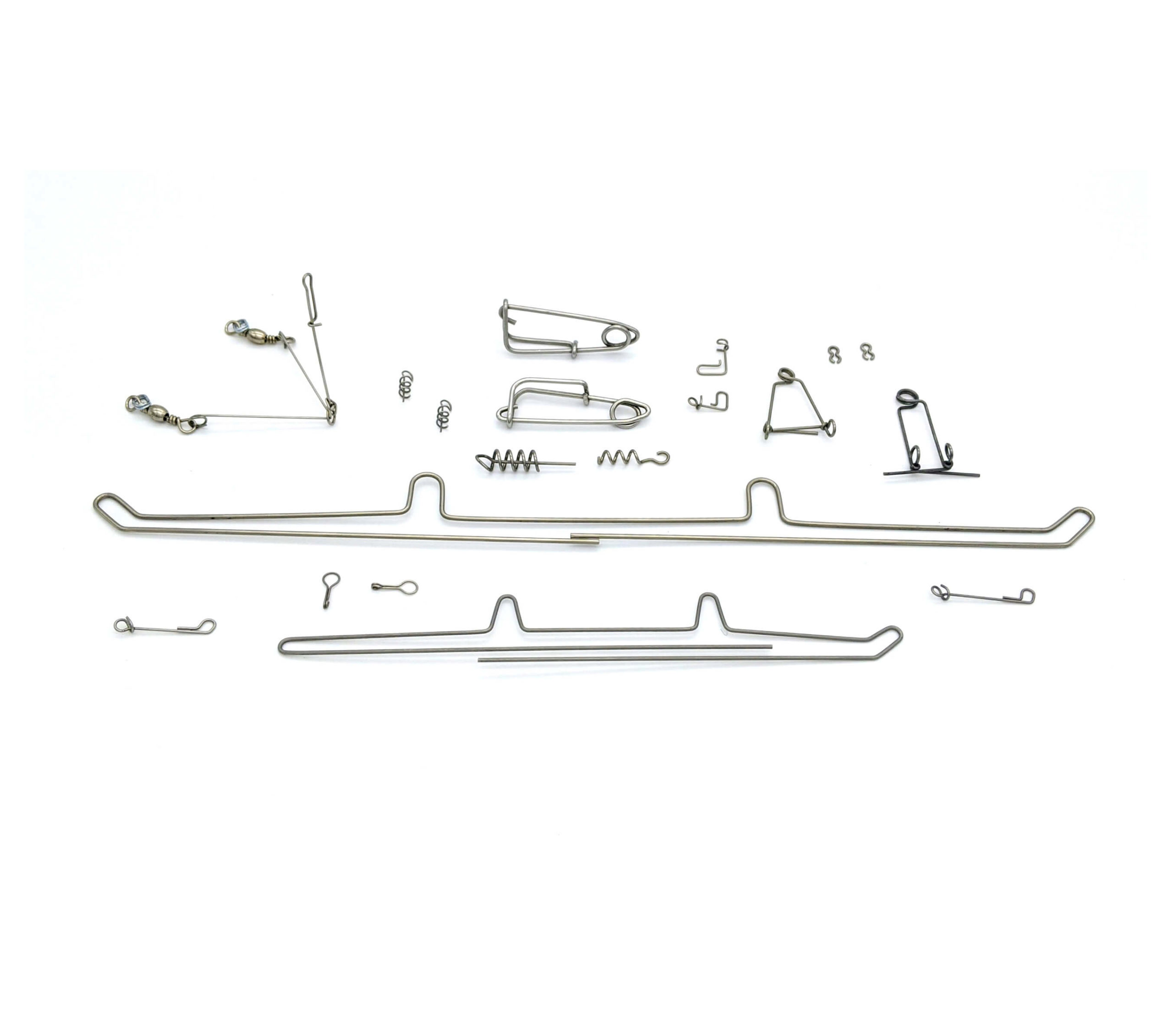

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs, ubiquitous in various mechanical systems, play a vital role in storing and releasing mechanical energy. They are essential components in countless applications, from automotive suspension systems to everyday

Compression springs, ubiquitous in various mechanical systems, play a vital role in storing and releasing mechanical energy. They are essential components in countless applications, from automotive suspension systems to everyday household appliances. This comprehensive guide delves into the fascinating world of compression springs, exploring their characteristics, types, design considerations, and applications.

Compression springs, as the name suggests, are coiled helical springs designed to absorb and release energy when compressed. They are typically made from metal wire, often steel, that is wound into a helix. The spring's ability to store and release energy stems from its inherent elasticity, a property that allows it to return to its original shape after being deformed.

The key characteristics of a compression spring that determine its functionality and performance include:

• **Spring Rate (k):** This value represents the force required to compress the spring by a specific distance. A higher spring rate indicates that the spring is stiffer, requiring more force to compress it.

• **Free Length (Lf):** The free length is the length of the spring when it is not subjected to any load. It is a critical dimension used in spring design and selection.

• **Solid Height (Ls):** The solid height is the minimum length the spring can be compressed to before the coils come into contact with each other. It is important to avoid compressing the spring beyond its solid height, as this can damage the spring.

• **Wire Diameter (d):** The diameter of the wire used to manufacture the spring directly influences its strength and flexibility. A thicker wire results in a stronger spring, while a thinner wire yields a more flexible spring.

• **Coil Diameter (D):** The diameter of the helix determines the spring's overall size and its ability to store energy. A larger coil diameter generally results in a higher energy storage capacity.

• **Number of Coils (N):** The number of coils directly affects the spring's rate and length. More coils result in a lower spring rate and a longer free length.

Compression springs come in various designs, each tailored to specific applications and requirements. Common types include:

• **Standard Compression Springs:** These are the most basic type, consisting of a helical coil of constant wire diameter and coil diameter.

• **Conical Compression Springs:** These springs have a gradual taper in their coil diameter, providing a progressive rate that increases as the spring is compressed. This characteristic is beneficial for applications requiring variable spring forces.

• **Variable Rate Compression Springs:** These springs have a non-linear rate, allowing for customized force profiles. They achieve this by varying the wire diameter, coil diameter, or the spacing between coils.

• **Torsion Compression Springs:** These springs are designed to be compressed in a direction perpendicular to the spring's axis. They typically have a special hook or eyelet to facilitate compression.

Designing a compression spring involves several critical considerations, including:

• **Load Capacity:** The spring must be able to withstand the maximum load it will be subjected to without exceeding its yield strength or failing.

• **Deflection Range:** The spring should be designed to operate within a specific deflection range to ensure optimal performance and prevent damage.

• **Spring Rate:** The spring rate needs to be tailored to the application, providing the appropriate force response for the intended function.

• **Material Selection:** Choosing the right material is crucial for achieving the desired spring properties. Factors like strength, corrosion resistance, and temperature tolerance are important considerations.

• **Manufacturing Process:** The chosen manufacturing method, such as cold coiling or hot coiling, will impact the spring's properties and cost.

Compression springs are indispensable components in a wide range of applications across various industries. Some prominent examples include:

• **Automotive Industry:** Compression springs are extensively used in automotive suspensions, clutch systems, and engine valve systems. They provide the necessary force to return components to their original positions after being compressed.

• **Aerospace Industry:** Compression springs play a crucial role in aerospace applications, including landing gear, actuators, and safety systems. They are often required to withstand extreme temperatures and pressures.

• **Medical Devices:** Compression springs are used in medical devices like surgical instruments, prosthetic limbs, and medical equipment. They provide precise force control and stability.

• **Household Appliances:** Compression springs are commonly found in everyday appliances, including refrigerators, washing machines, and ovens. They power mechanisms such as door latches, water valves, and thermostats.

• **Industrial Machinery:** Compression springs are essential in industrial machinery, where they are used in lifting devices, clamping mechanisms, and various other applications. They provide reliable force generation and energy storage.

Selecting the right compression spring for your application requires careful consideration of several factors:

• **Application Requirements:** Define the specific load, deflection range, and other performance requirements for your application.

• **Environmental Conditions:** Consider the temperature, pressure, and other environmental factors that the spring will be exposed to.

• **Available Space:** Determine the available space for the spring within the design constraints.

• **Cost Considerations:** Evaluate the cost of different spring options, balancing performance requirements with budget limitations.

Compression springs are ubiquitous in modern engineering, offering reliable force generation and energy storage capabilities. Understanding their characteristics, types, design considerations, and applications is essential for engineers and designers seeking to leverage their potential in various mechanical systems. By carefully choosing the right spring for a specific application, engineers can ensure optimal performance and reliability, enhancing the functionality and longevity of their designs.

Compression springs, with their inherent elasticity and diverse design options, continue to play a vital role in numerous mechanical systems across various industries. Their ability to store and release mechanical energy makes them indispensable components in applications ranging from automotive systems to medical devices. By embracing their unique characteristics and considering the design factors carefully, engineers can effectively harness the power of compression springs to create innovative and reliable solutions.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.