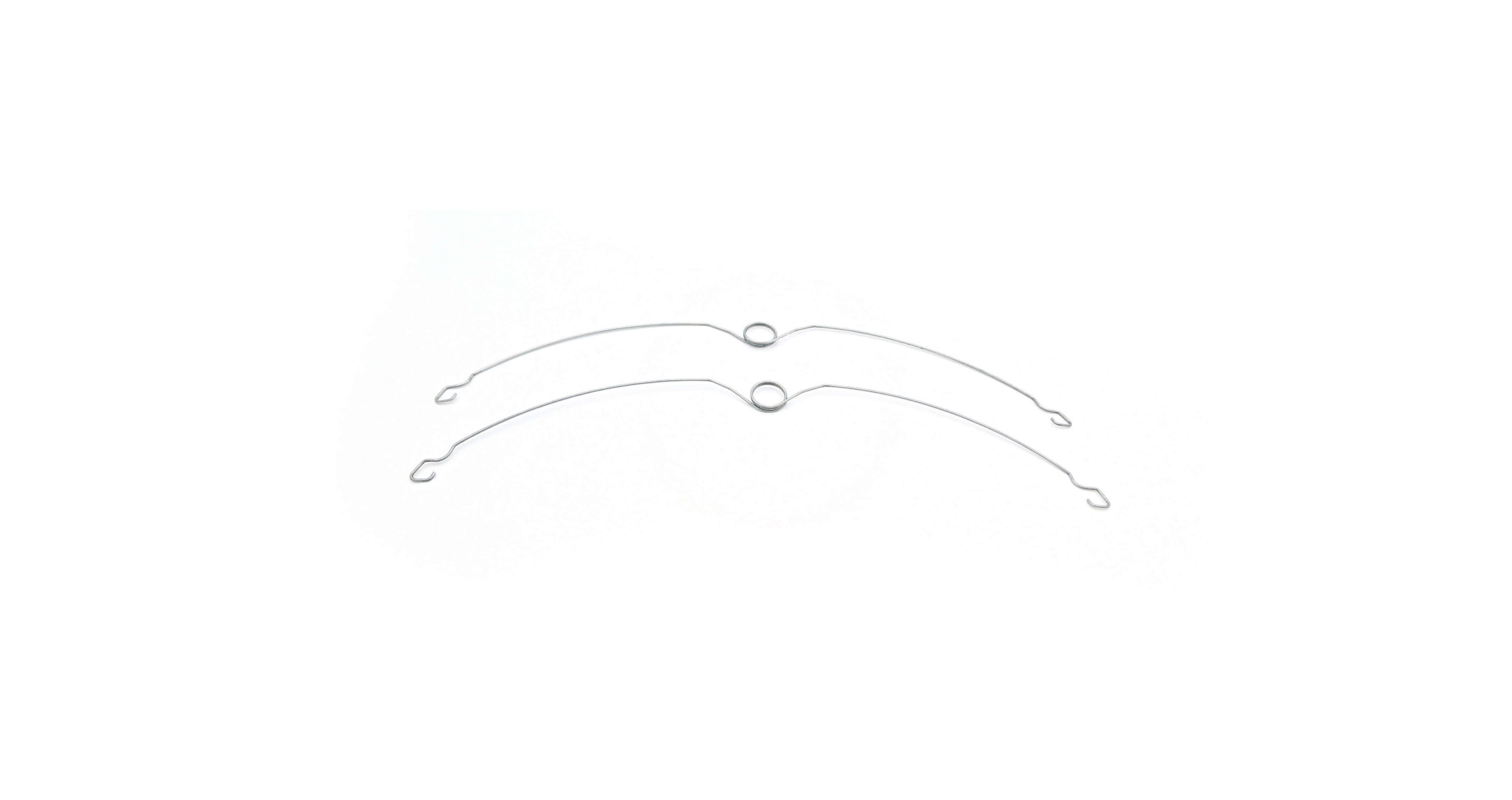

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of engineering and design, the humble compression spring plays a vital role. These coiled marvels, often made from stainless steel, are the unsung heroes behind countless mechanisms,

In the world of engineering and design, the humble compression spring plays a vital role. These coiled marvels, often made from stainless steel, are the unsung heroes behind countless mechanisms, ensuring smooth operation and reliable performance. From delicate medical devices to heavy-duty industrial machinery, compression springs stainless offer a combination of strength, resilience, and resistance that's hard to beat. So, if you're looking for a spring that can withstand the test of time and the rigors of demanding applications, then look no further. Let's delve into the world of compression springs stainless and uncover what makes them so exceptional.

Compression springs are a type of helical spring designed to resist compressive forces. They are commonly used in various applications, from simple door hinges to complex automotive suspensions. Compression springs stainless are crafted from stainless steel, an alloy renowned for its resistance to corrosion and its ability to withstand extreme temperatures and harsh environments. This makes them ideal for applications where durability and longevity are paramount.

Stainless steel, unlike ordinary steel, contains a significant amount of chromium, usually at least 10.5%. This chromium forms a protective oxide layer on the surface, known as a passive layer, which shields the underlying steel from corrosion. This inherent corrosion resistance makes stainless steel springs ideal for use in applications where exposure to moisture, chemicals, or other corrosive agents is a concern. Think of it as a superhero's shield, protecting the spring from the elements and ensuring it stays strong and reliable, even under challenging conditions.

Compression springs stainless offer a host of advantages, making them a top choice for engineers and designers across industries.

The versatility of compression springs stainless makes them suitable for a wide range of applications, including:

When selecting compression springs stainless, it's crucial to consider the following factors to ensure you choose the right spring for your application:

Compression springs stainless are an indispensable component in a wide range of applications. Their exceptional strength, corrosion resistance, and temperature tolerance make them the ideal choice for demanding environments where reliability and durability are critical. By considering the key factors mentioned above, you can confidently choose the right compression spring stainless for your specific needs and ensure its long-lasting performance.

Remember, a good compression spring is often the unsung hero of a design. It's the hidden force that keeps things moving smoothly and reliably. With their strength, resilience, and corrosion resistance, compression springs stainless are the ultimate choice for durability and performance. So, the next time you're working on a project, remember the power of the compression spring stainless, and embrace its ability to make your designs truly exceptional!

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.