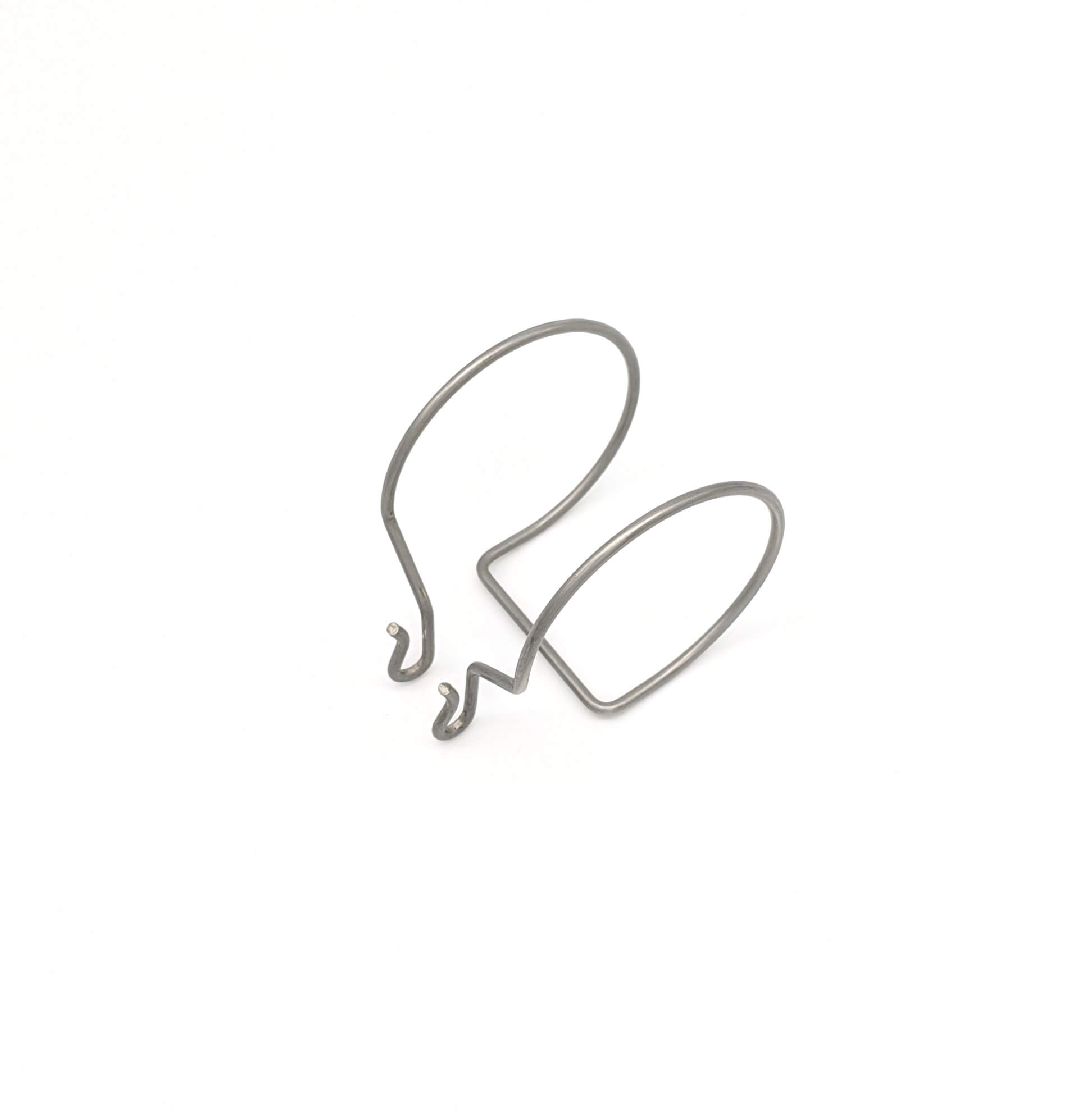

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of industrial design, where form often meets function, compression spring latches quietly play a pivotal role. These seemingly simple components, often overlooked amidst the grandeur of intricate

In the world of industrial design, where form often meets function, compression spring latches quietly play a pivotal role. These seemingly simple components, often overlooked amidst the grandeur of intricate mechanisms, are the unsung heroes holding countless products together. From the everyday appliance to complex industrial machinery, compression spring latches ensure secure closures, guaranteeing peace of mind and preventing unwanted mishaps. This article delves into the fascinating world of compression spring latches, exploring their design, applications, and the benefits they bring to diverse industries.

Compression spring latches, also known as spring-loaded latches, are mechanical devices that utilize the force of a compressed spring to secure a closure mechanism. They consist of a latch body, a spring, and a release mechanism. When the latch is engaged, the spring applies a constant force, holding the latch in place. This force can be released by a simple action, such as pressing a lever, pushing a button, or turning a knob.

Compression spring latches come in a wide variety of designs, each tailored for specific applications. Some of the common types include:

Compression spring latches offer numerous advantages over other types of latching mechanisms, making them a preferred choice in many industries:

Compression spring latches are used in a wide range of applications, including:

When selecting a compression spring latch for a particular application, several factors should be considered:

Compression spring latches are essential components in many products, ensuring secure closures and preventing unwanted mishaps. Their simplicity, reliability, and versatility make them an indispensable part of modern design. By understanding the different types, advantages, and factors to consider, designers can select the most suitable compression spring latch for their specific application, ensuring the optimal performance and longevity of their products.

Compression spring latches are often the unsung heroes of design, quietly performing their duty with unwavering reliability. They are the glue that holds many things together, ensuring safety and efficiency. Their importance cannot be overstated, as they are the backbone of many industrial and consumer applications. The next time you encounter a latch, take a moment to appreciate its unassuming yet essential role in our daily lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.