Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs are ubiquitous in our daily lives, from the simple act of opening a pen to complex machinery operating at high speeds. Understanding the intricacies of compression springs and

Compression springs are ubiquitous in our daily lives, from the simple act of opening a pen to complex machinery operating at high speeds. Understanding the intricacies of compression springs and how to calculate their properties is crucial for anyone working with or designing mechanical systems. Thankfully, numerous online tools like compression spring calculators exist to simplify this process, providing valuable insights into spring behavior and performance.

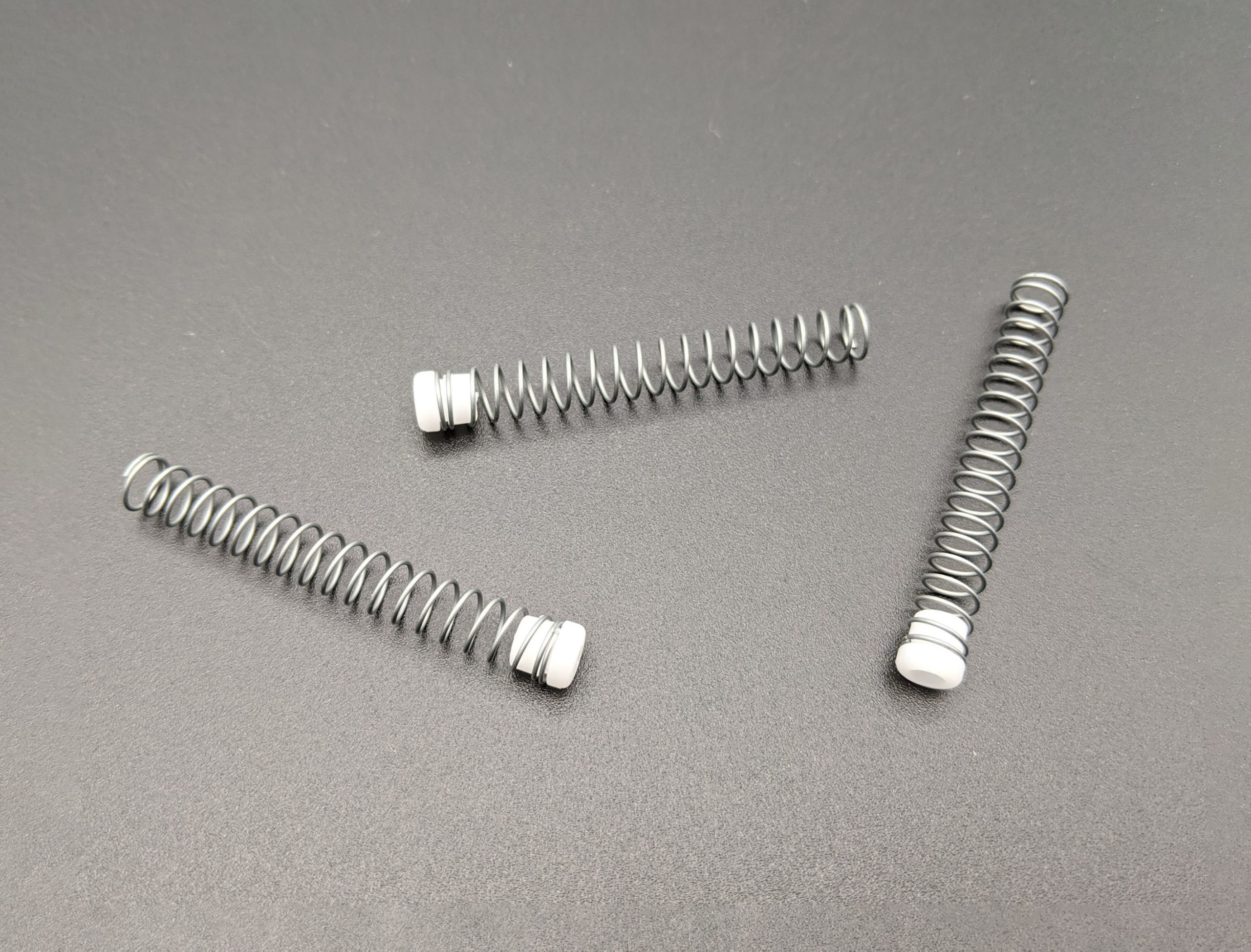

Compression springs are helical coils made of elastic materials, such as steel or other metals, designed to resist compression forces. When a load is applied, the spring compresses, storing potential energy. Upon removal of the load, the spring returns to its original shape, releasing the stored energy. The properties of a compression spring, like its stiffness and force, depend on various factors, including the material, wire diameter, number of coils, and spring free length.

Calculating the characteristics of a compression spring is essential for ensuring it performs as intended within a specific application. Several factors influence these calculations, each with its own formula and significance.

The spring rate, often referred to as the spring constant, is a measure of how much force is required to compress the spring by a specific distance. A higher spring rate indicates that more force is needed to compress the spring. The formula for calculating the spring rate is:

k = (Gd^4) / (8D^3n)

Where:

* k = Spring rate (lbs/inch or N/mm)

* G = Modulus of rigidity of the spring material (psi or N/mm^2)

* d = Wire diameter (inches or mm)

* D = Mean coil diameter (inches or mm)

* n = Number of active coils

The spring force is the force exerted by the spring when compressed or extended. This force is directly proportional to the spring rate and the compression or extension distance. The formula for calculating spring force is:

F = k * x

Where:

* F = Spring force (lbs or N)

* k = Spring rate (lbs/inch or N/mm)

* x = Compression or extension distance (inches or mm)

The solid height of a compression spring is the minimum height it can achieve when fully compressed. It is calculated by:

Solid height = Number of coils * Wire diameter

The free length is the overall length of the spring when it is not compressed. It is a critical parameter for determining the spring's operating range and avoiding spring binding.

Manually performing these calculations can be time-consuming and prone to errors. Thankfully, online compression spring calculators provide a convenient solution. These tools typically require users to input basic spring parameters, such as wire diameter, mean coil diameter, number of coils, and material type. The calculator then automatically determines the spring rate, force, solid height, and other relevant parameters.

1. Accuracy: Calculators employ precise formulas to ensure accurate results, minimizing the risk of human error.

2. Efficiency: Calculators streamline the calculation process, saving time and effort.

3. Flexibility: Many calculators allow users to experiment with different spring parameters, enabling rapid prototyping and design optimization.

4. Accessibility: Online calculators are readily available, making them convenient and accessible to anyone.

When selecting a compression spring calculator, consider these factors:

1. Features: Ensure the calculator offers the specific features you require, such as the ability to calculate various spring parameters or incorporate different material types.

2. User Interface: Choose a calculator with a user-friendly interface that is intuitive and easy to navigate.

3. Accuracy: Verify that the calculator uses accurate formulas and reliable algorithms.

Compression springs find applications in a wide range of industries, including:

1. Automotive: Suspension systems, clutches, and engine components.

2. Aerospace: Landing gear, actuators, and control systems.

3. Manufacturing: Machinery, tooling, and clamping devices.

4. Electronics: Keyboard buttons, switches, and connectors.

5. Medical: Surgical instruments, medical devices, and prosthetic limbs.

Compression springs are fundamental components in countless mechanical systems. Understanding their behavior and accurately calculating their properties is crucial for ensuring proper functionality and performance. Online compression spring calculators offer a valuable tool for designers and engineers, providing a convenient and efficient method for determining spring characteristics. By leveraging these calculators, you can save time, enhance accuracy, and optimize your spring designs.

Whether you're a seasoned engineer or a hobbyist, understanding the fundamentals of compression springs and utilizing tools like calculators can greatly improve your design and problem-solving capabilities. With a little knowledge and the right resources, you can confidently select, design, and implement compression springs for a wide range of applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.