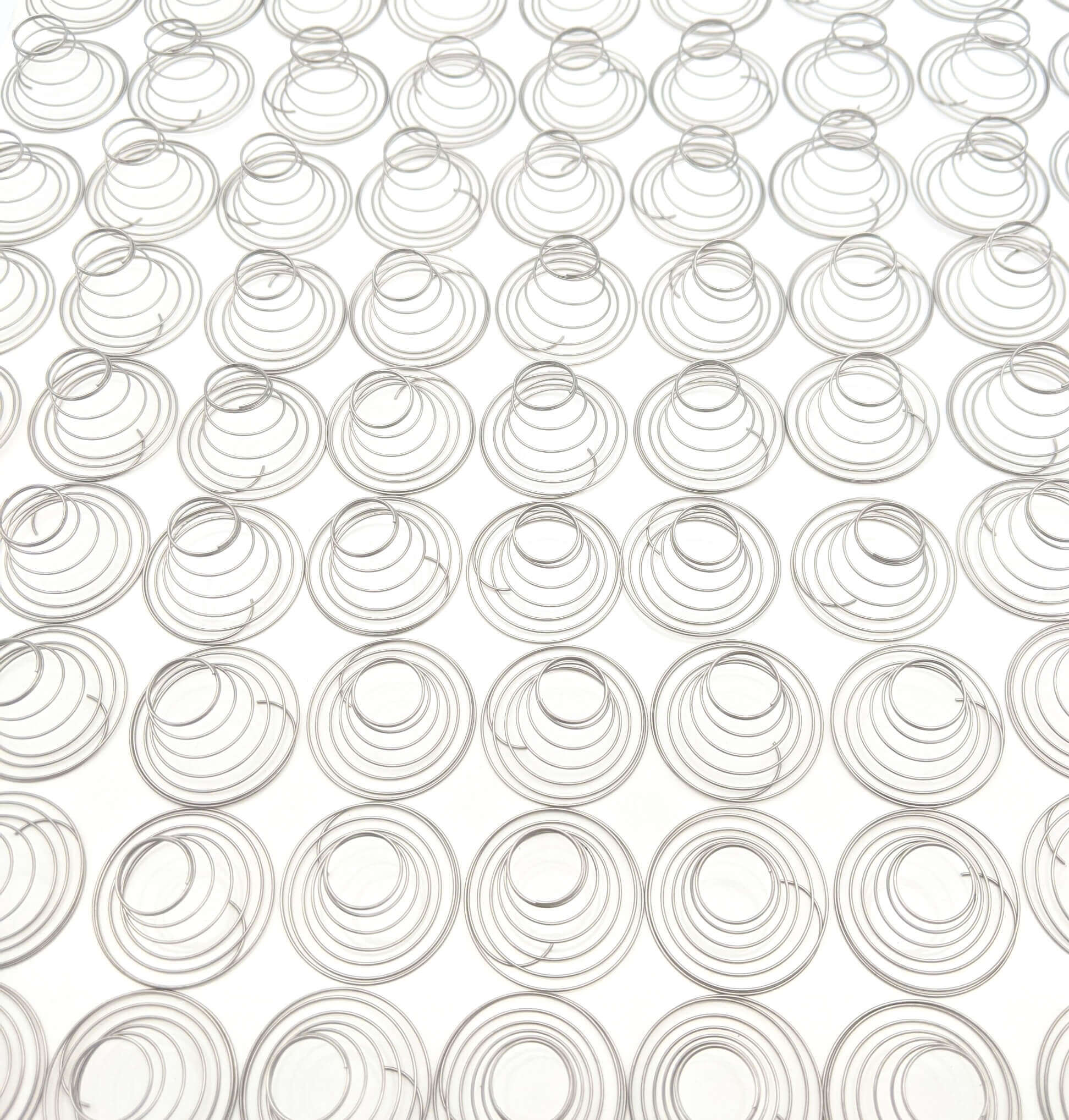

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression gas springs, also known as gas struts, are powerful and versatile mechanical devices that harness the power of compressed gas to provide controlled, smooth, and reliable motion in various

Compression gas springs, also known as gas struts, are powerful and versatile mechanical devices that harness the power of compressed gas to provide controlled, smooth, and reliable motion in various applications. These springs, unlike traditional mechanical springs, offer numerous advantages, including adjustable damping, compact size, and long service life. They are widely used in automotive, industrial, medical, and consumer products, contributing to safety, efficiency, and ease of use in countless applications.

Compression gas springs are essentially sealed cylinders containing pressurized gas, typically nitrogen, and a piston. When the spring is compressed, the gas inside is compressed further, increasing its pressure. This increase in pressure creates a force that resists further compression, much like a traditional spring. The key difference lies in the fact that the force generated by a gas spring is not linear, but rather follows a non-linear curve.

This non-linear force characteristic allows gas springs to provide a wide range of forces and damping levels, making them suitable for diverse applications. The amount of force and damping can be fine-tuned by adjusting the pressure of the gas and the design of the piston.

Compression gas springs offer a plethora of benefits that make them a preferred choice over traditional mechanical springs in many applications:

1. Smooth and Controlled Motion: Gas springs provide smooth and controlled motion, ensuring a consistent and predictable movement. Unlike mechanical springs, which can be jerky and prone to vibrations, gas springs dampen the movement, creating a more refined and controlled experience.

2. Adjustable Damping: The damping characteristics of gas springs can be easily adjusted by modifying the piston design. This allows engineers to fine-tune the spring's behavior to meet specific application requirements. For instance, a gas spring can be designed to provide a soft, gradual opening in one application and a quick, forceful closing in another.

3. Compact Size: Gas springs are incredibly compact and lightweight, making them ideal for applications where space is limited. Their compact design allows for efficient use of space, particularly in automotive and industrial settings.

4. Long Service Life: Gas springs are known for their durability and long service life. Unlike mechanical springs, which can fatigue and wear out over time, gas springs are relatively maintenance-free and can endure extensive cycles of use.

5. Safe and Reliable: Gas springs are designed to withstand high pressures and are rigorously tested for safety and reliability. The sealed cylinder prevents gas leakage and ensures consistent performance over time.

Compression gas springs find applications in a wide range of industries and products. Some common examples include:

Automotive:

Industrial:

Medical:

Consumer Products:

Selecting the appropriate compression gas spring for a specific application requires careful consideration of several factors:

Working with a reputable manufacturer or distributor of gas springs can provide expert guidance and ensure the selection of the ideal spring for your application.

Compression gas springs are a powerful and versatile solution for various applications, offering a unique combination of smooth motion, adjustable damping, compact size, long service life, and safety. Their adaptability and reliability make them an indispensable component in countless products, enhancing user experience and ensuring reliable operation across diverse industries.

As technology continues to evolve, compression gas springs are likely to play an increasingly vital role in creating innovative and efficient solutions. Their ability to provide controlled motion with adjustable damping makes them a valuable asset for designers and engineers seeking to improve functionality and user experience in various applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.