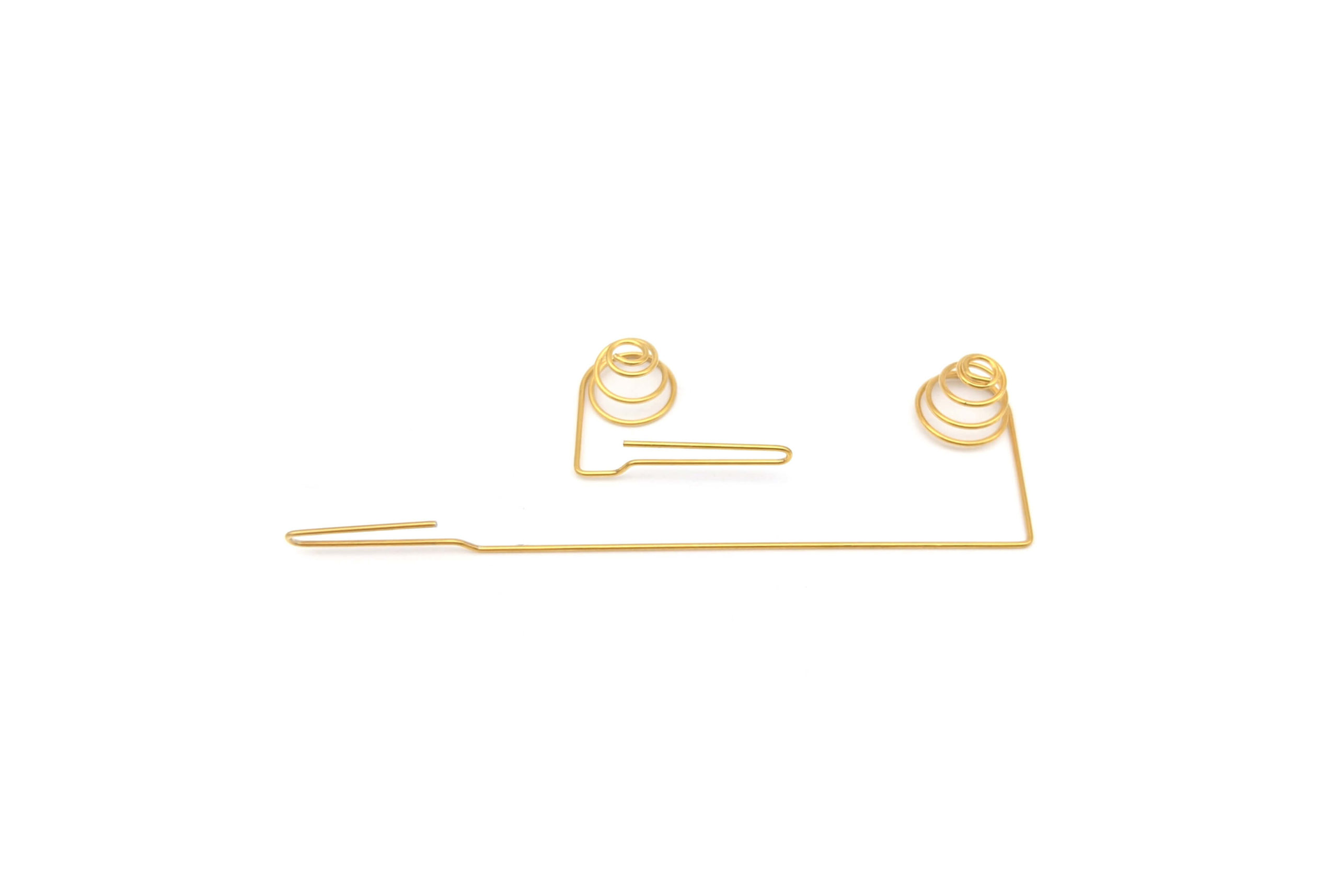

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression gas springs, also known as gas struts or gas springs, are powerful and versatile devices that utilize the pressure of compressed gas to provide a controlled and consistent force.

Compression gas springs, also known as gas struts or gas springs, are powerful and versatile devices that utilize the pressure of compressed gas to provide a controlled and consistent force. They're found in countless applications, from car trunks and hoods to furniture and medical equipment, offering a smooth, reliable, and often space-saving alternative to traditional mechanical springs. In this article, we'll delve into the fascinating world of compression gas springs, exploring their design, operation, advantages, and wide range of applications.

At their core, compression gas springs are simple yet ingenious devices. They consist of a sealed cylinder filled with a pressurized gas, typically nitrogen. A piston within the cylinder is connected to a rod, which extends outside the cylinder. When the rod is pushed in, the gas within the cylinder is compressed, storing potential energy. When the force is released, the gas expands, pushing the rod out and applying a force in the opposite direction. This force is what makes gas springs so useful in various applications.

One of the key advantages of compression gas springs is their ability to provide a constant force throughout their stroke. Unlike traditional coil springs, whose force decreases as they compress, gas springs maintain a consistent force, resulting in smooth, controlled movement. This makes them ideal for applications where precise force control is crucial, such as lifting heavy doors or hatches.

Compression gas springs offer numerous advantages over traditional mechanical springs, making them a popular choice for a wide range of applications. Some of the most notable benefits include:

Smooth and Controlled Movement: Gas springs provide a smooth, consistent force throughout their entire stroke, eliminating the jerky or unpredictable movements often associated with mechanical springs.

Constant Force: Unlike coil springs, whose force decreases as they compress, gas springs maintain a consistent force, ensuring reliable and predictable performance.

Space Efficiency: Gas springs are compact and can be designed to fit in tight spaces, offering a more efficient use of space compared to bulky mechanical springs.

Durability: Well-designed gas springs are remarkably durable and can withstand repeated cycles of compression and extension, ensuring a long lifespan. They're resistant to corrosion, wear, and tear, making them ideal for demanding applications.

Customizable Force and Stroke: Gas springs can be customized to provide specific force and stroke characteristics, ensuring they perfectly match the requirements of any given application.

Compression gas springs are truly ubiquitous. Their versatility and reliability have led to their widespread adoption across numerous industries and applications. Here are a few examples:

Automotive: Gas springs are essential in modern automobiles, used to lift and support hoods, trunks, and tailgates. They offer a smooth and effortless experience, allowing for easy access to the engine compartment or cargo space.

Furniture: Gas springs are commonly used in furniture, such as reclining chairs, office chairs, and sofa beds. They provide a comfortable and adjustable seating experience, allowing users to easily adjust the position and height of their furniture.

Medical Equipment: Gas springs play a vital role in medical equipment, such as operating tables, patient beds, and medical carts. They ensure smooth and controlled movement, providing a safe and comfortable experience for both patients and medical professionals.

Industrial Machinery: Gas springs are used in industrial equipment, such as lifting platforms, doors, and hatches. They offer reliable and powerful lifting capabilities, while also providing smooth and controlled movement for increased safety and efficiency.

Other Applications: Compression gas springs are found in a wide range of other applications, including:

Choosing the right compression gas spring for a specific application is essential to ensure optimal performance and safety. Here are some key factors to consider:

By carefully considering these factors, you can select a compression gas spring that will perform reliably and efficiently for your specific needs.

Compression gas springs are indispensable components in a wide range of modern applications. Their ability to provide smooth, controlled, and consistent force makes them an excellent choice for applications where traditional mechanical springs fall short. From lifting car hoods to adjusting furniture and operating medical equipment, gas springs are truly a testament to the ingenuity of modern engineering. Understanding their design, advantages, and applications will help you appreciate their remarkable impact on our daily lives.

Compression gas springs have revolutionized numerous industries, offering a reliable, efficient, and often space-saving solution to various challenges. Their versatility, durability, and customizable features make them a valuable asset in various applications. As technology continues to advance, we can expect to see even more innovative uses for these powerful and versatile devices.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.