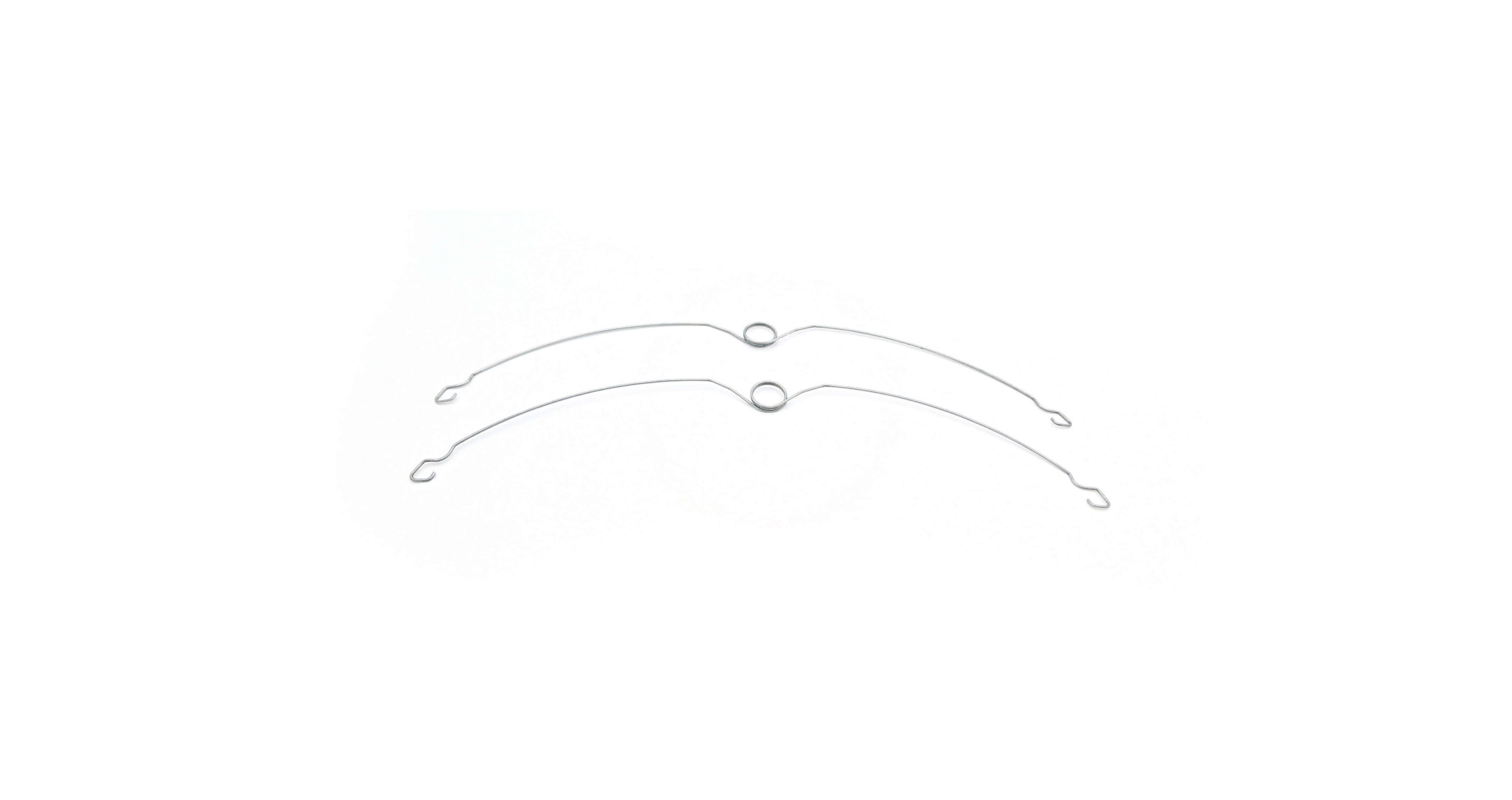

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression gas springs, also known as gas struts, are powerful and versatile devices that provide controlled motion and support in a wide range of applications. They are essentially cylinders filled

Compression gas springs, also known as gas struts, are powerful and versatile devices that provide controlled motion and support in a wide range of applications. They are essentially cylinders filled with pressurized gas that generate a force when compressed. These springs are favored for their compact size, durability, and ability to provide a consistent force throughout their travel. In this article, we will delve into the workings, benefits, and diverse applications of compression gas springs, showcasing their significance in modern engineering and design.

At their core, compression gas springs consist of a sealed cylinder containing pressurized nitrogen gas. When compressed, the gas expands, generating a force that resists compression and facilitates smooth, controlled motion. This force is determined by the volume of gas, the pressure inside the cylinder, and the piston's area. The design allows for customization of the spring's force and stroke length, tailoring it to specific application requirements.

The key advantage of compression gas springs lies in their ability to provide a consistent force throughout their entire stroke. This makes them ideal for applications where a steady resistance is crucial. Unlike conventional mechanical springs, which tend to lose their force as they are compressed, gas springs maintain their force profile, ensuring reliable performance over time.

Compression gas springs offer numerous advantages that make them a compelling choice for diverse applications:

**Compact and Lightweight:** One of the most notable benefits of gas springs is their compact size. They can be significantly smaller than mechanical springs, reducing the overall size and weight of the equipment or system they are used in. This is particularly advantageous in space-constrained applications.

**Smooth and Controlled Motion:** Gas springs provide smooth and controlled motion, eliminating the jarring and jerky movements often associated with mechanical springs. This is crucial in applications requiring precise movement, such as in automotive liftgates, medical equipment, and industrial machinery.

**Durable and Reliable:** Gas springs are designed to withstand harsh environments and repeated cycles of compression and extension. They are resistant to corrosion, wear, and tear, ensuring long-lasting performance and minimizing maintenance needs.

**Customizable Force and Stroke:** Gas springs are highly customizable, allowing engineers to tailor the force and stroke length to specific application requirements. This flexibility makes them suitable for a wide range of applications, from delicate instruments to heavy-duty machinery.

**Safety Features:** Most gas springs incorporate safety features such as end stops and over-pressure protection, preventing damage and ensuring user safety.

Compression gas springs have found widespread use in a multitude of industries and applications. Their versatility and reliability have made them an indispensable component in various sectors, including:

**Automotive:** Gas springs are commonly used in automotive liftgates, hoods, and trunk lids, providing smooth and controlled opening and closing mechanisms. Their compact size allows for integration into limited spaces, while their durability ensures long-lasting performance.

**Medical Equipment:** Gas springs are crucial in medical equipment such as hospital beds, operating tables, and medical carts. They offer controlled movement, stability, and support, ensuring patient safety and comfort.

**Industrial Machinery:** Gas springs are used in industrial machinery such as presses, conveyors, and lifting equipment. They provide powerful support, smooth movement, and reliable operation in demanding environments.

**Furniture:** Gas springs are incorporated in furniture such as office chairs, recliner chairs, and sofa beds. They provide adjustable height, smooth reclining motion, and ease of use.

**Consumer Products:** Gas springs are also found in consumer products such as laptops, tablet stands, and portable lighting. Their compact size and ability to provide a consistent force make them suitable for these applications.

Choosing the right compression gas spring for your application requires careful consideration of various factors:

**Force and Stroke:** Determine the required force and stroke length for your application. The force should be sufficient to overcome the weight or resistance, while the stroke length should match the movement requirements.

**Operating Environment:** Consider the operating temperature, humidity, and other environmental factors that may affect the performance of the gas spring.

**Mounting Options:** Choose a mounting option that is compatible with your application and provides secure installation.

**Safety Considerations:** Ensure that the chosen gas spring has safety features such as end stops and over-pressure protection.

Compression gas springs are a versatile and reliable solution for various applications. Their compact size, smooth and controlled motion, durability, and customizable features make them a preferred choice across diverse industries. Understanding their advantages, applications, and selection considerations will help engineers and designers effectively utilize these powerful devices, optimizing the performance and functionality of their products and systems.

Compression gas springs offer a powerful and convenient solution for a wide range of engineering challenges. Their ability to provide smooth, controlled motion, along with their compact size and durability, makes them ideal for applications where reliability and performance are paramount. Whether it's a car liftgate, a hospital bed, or a piece of industrial equipment, compression gas springs play a vital role in ensuring smooth and efficient operation. As technology continues to advance, these versatile devices are likely to find even more applications in the future.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.