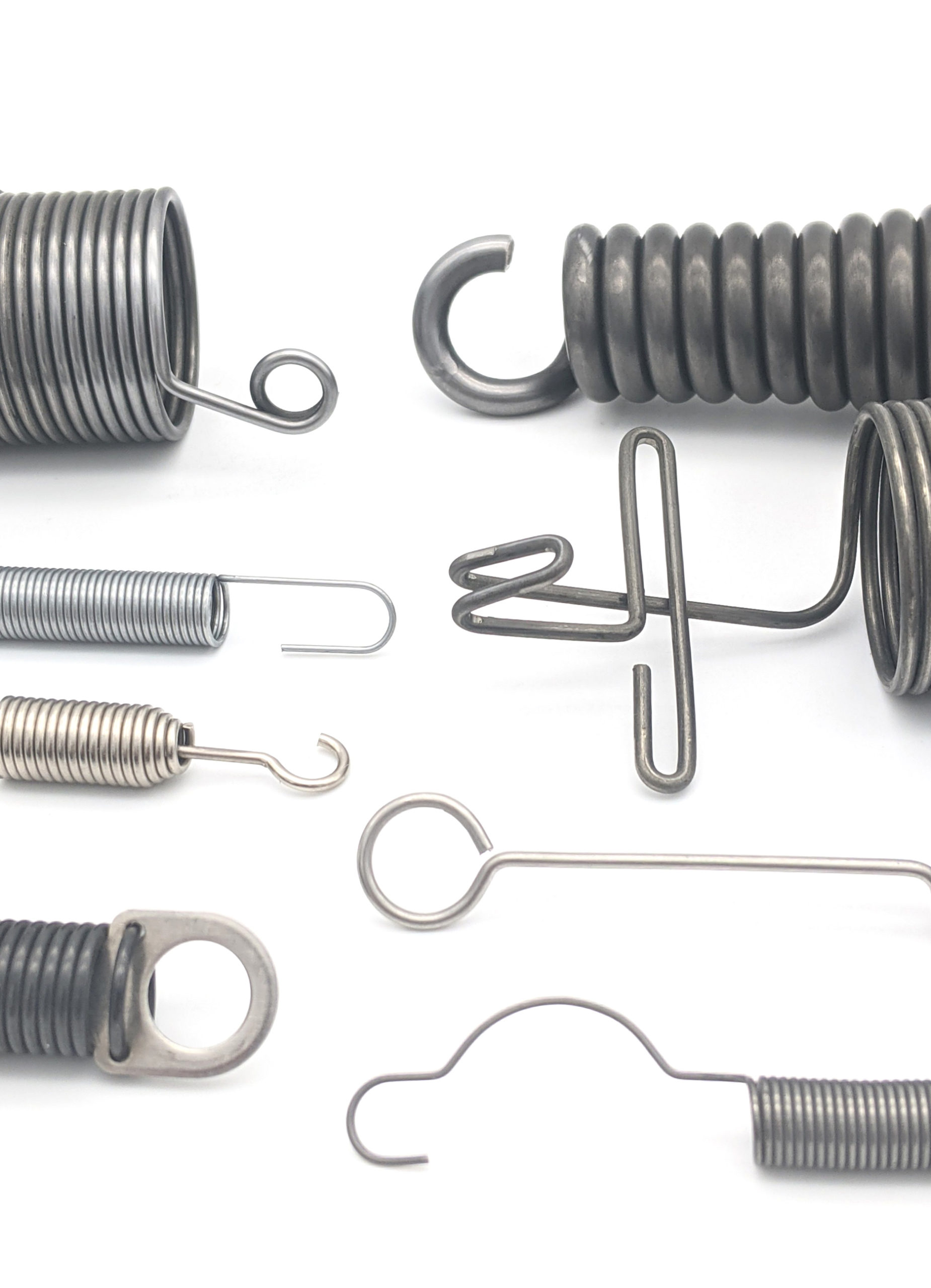

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression coil springs are ubiquitous in our world, silently working behind the scenes to provide essential functions in countless applications. From the suspension systems of vehicles to the intricate mechanisms

Compression coil springs are ubiquitous in our world, silently working behind the scenes to provide essential functions in countless applications. From the suspension systems of vehicles to the intricate mechanisms of watches, these helical wonders play a crucial role in absorbing shock, storing energy, and providing a reliable force to various systems. In this article, we will delve into the fascinating world of compression coil springs, exploring their design, working principle, applications, and the factors that influence their performance.

Compression coil springs, as their name suggests, are helical springs designed to resist compression forces. They are typically made of high-quality steel wire, meticulously coiled to form a cylindrical or conical shape. The spring's ability to store and release energy comes from its inherent elasticity. When a compressive force is applied, the coils of the spring compress, storing potential energy. When the force is removed, the spring expands, releasing the stored energy.

The design of a compression coil spring is paramount to its functionality. Factors such as the wire diameter, coil diameter, number of coils, and the material used all contribute to the spring's characteristics, such as its spring rate, load capacity, and fatigue resistance. The spring rate, often denoted as 'k', represents the stiffness of the spring, indicating the force required to compress it by a specific distance. A higher spring rate corresponds to a stiffer spring, requiring greater force for compression.

Compression coil springs find widespread use in countless applications across diverse industries. Some prominent examples include:

The versatility of compression coil springs stems from their ability to be tailored to specific requirements. By carefully selecting the material, wire diameter, coil diameter, and number of coils, engineers can create springs with specific spring rates, load capacities, and fatigue resistances, enabling them to meet the demands of various applications.

The performance of a compression coil spring is influenced by several factors. It's crucial to consider these factors during design and selection to ensure the spring meets the required specifications and performs optimally.

Compression coil springs are integral components in countless applications, providing essential functions like shock absorption, energy storage, and force generation. Their design, material selection, and manufacturing process are crucial for achieving optimal performance and reliability. By understanding the key factors influencing their performance, engineers can design and select compression springs that meet specific requirements and ensure the smooth operation of various systems. The versatility and reliability of compression coil springs make them indispensable in our modern world, playing a silent but vital role in countless applications we encounter daily.

Compression coil springs are a testament to the ingenuity and precision of engineering. Their simple yet effective design allows them to perform vital tasks in diverse applications, seamlessly blending into the fabric of our modern world. Understanding their role and importance helps us appreciate the intricate mechanics that power our everyday lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.