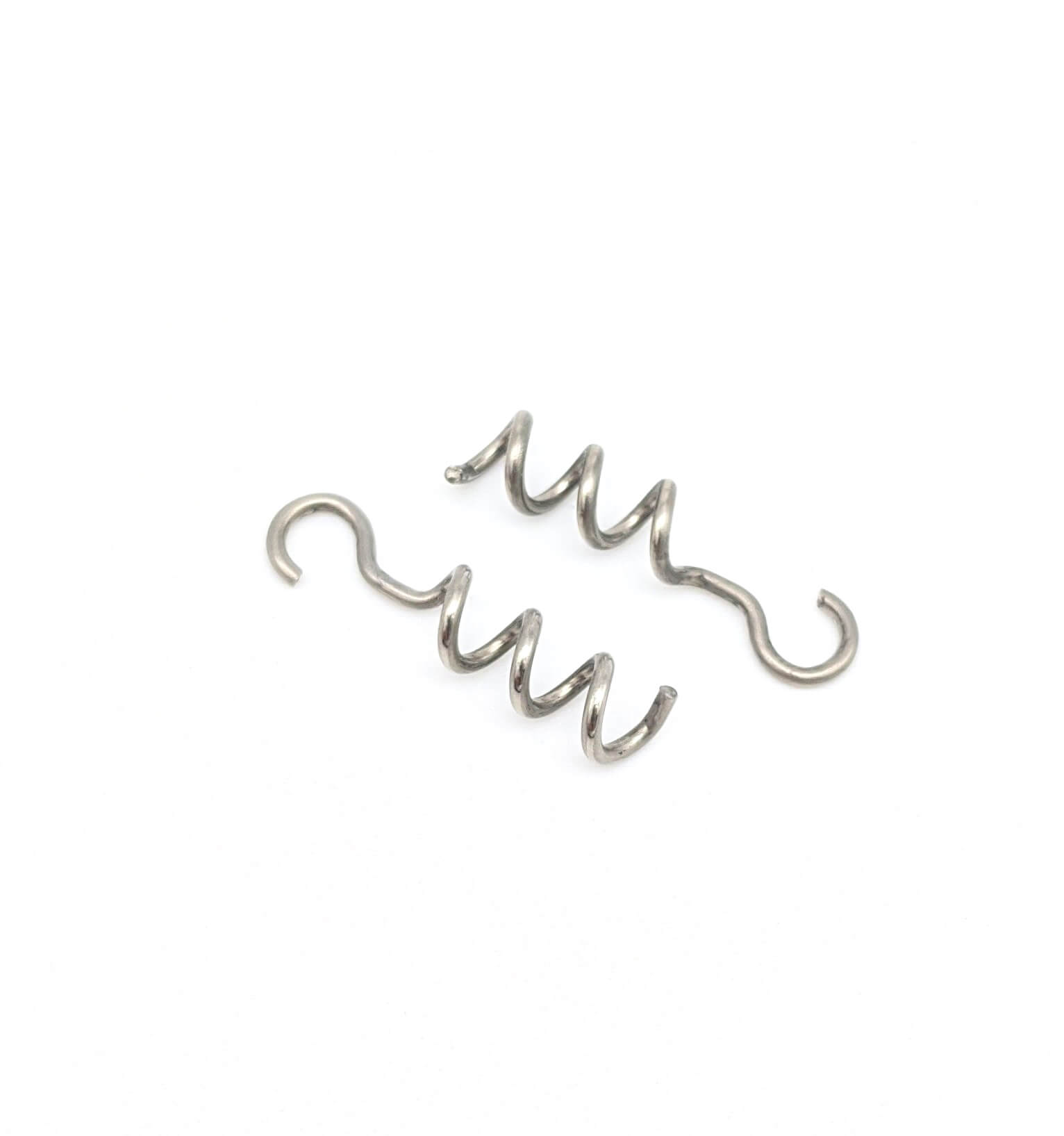

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression coil springs are ubiquitous in our modern world, silently performing their duty in countless mechanical systems. These seemingly simple devices are the backbone of many applications, from the humble

Compression coil springs are ubiquitous in our modern world, silently performing their duty in countless mechanical systems. These seemingly simple devices are the backbone of many applications, from the humble door closer to the intricate mechanisms of heavy machinery. Their ability to store and release energy, providing resistance to compression, makes them indispensable for a wide range of functions. In this article, we delve into the fascinating world of compression coil springs, exploring their construction, types, applications, and the key factors that influence their performance.

At their core, compression coil springs are helical springs designed to resist compressive forces. They are formed by coiling a wire, often made of spring steel, around a cylindrical mandrel. The coils of the spring are not touching in the unloaded state, allowing for a defined compression range. When a force is applied, the coils compress, storing potential energy. Once the force is removed, the spring's inherent elasticity pushes it back to its original shape, releasing the stored energy.

The construction of a compression coil spring is relatively straightforward but involves several critical factors that determine its performance. The spring's wire diameter, coil diameter, number of active coils, and material properties all play a significant role in its characteristics. The wire diameter directly influences the spring's stiffness, with a thicker wire resulting in a stiffer spring. The coil diameter determines the spring's length and compression range, while the number of active coils affects the spring's force and stiffness. The material selection, typically spring steel, influences the spring's strength, fatigue resistance, and ability to withstand environmental factors.

Compression coil springs come in various designs, each tailored for specific applications. Some common types include:

These are the most basic type, with uniform coil spacing and a consistent spring rate throughout the compression cycle. They are widely used in simple applications such as door closers, automotive suspension systems, and general-purpose clamping.

Variable rate compression springs offer varying stiffness throughout the compression cycle. This is achieved by varying the coil spacing, making the spring stiffer at higher compression levels. They find use in applications requiring progressive resistance, like heavy-duty machinery and shock absorbers.

Conical compression springs have a tapered design, with the coil diameter gradually decreasing along the spring's length. This configuration provides a higher spring rate at higher compression levels, often used in applications where space is limited and a high spring rate is required, such as in some automotive suspension systems.

Barrel compression springs have a larger coil diameter in the middle and smaller diameters at the ends. This design provides increased load-carrying capacity at the ends and reduces the risk of coil-to-coil contact during compression. They are used in applications demanding high force and stability, like heavy-duty machinery and lifting equipment.

The versatility of compression coil springs makes them indispensable in countless industries. Here are a few prominent examples:

Compression coil springs are vital components in vehicle suspension systems, absorbing shock and providing ride comfort. They are used in coil-over suspension systems, leaf springs, and other suspension designs.

Heavy-duty machinery, such as cranes, forklifts, and presses, relies on compression coil springs for various functions, including clamping, lifting, and shock absorption. They are crucial for ensuring smooth operation and preventing damage to equipment.

Compression coil springs are found in a wide range of consumer products, from the simple door closer and ballpoint pen to more complex appliances like washing machines and refrigerators. They are used to provide spring action, control movement, and absorb shocks in these everyday items.

The performance of a compression coil spring is influenced by several critical factors:

The spring rate is a measure of the spring's stiffness, defined as the change in force required for a unit change in length. It is expressed in units of force per distance, such as N/mm or lbf/in. A higher spring rate indicates a stiffer spring that requires more force to compress.

Spring deflection refers to the amount the spring compresses under a load. It is typically measured in millimeters or inches. The maximum deflection is limited by the spring's design and material properties. Exceeding the maximum deflection can lead to permanent deformation or spring failure.

The force exerted by a spring is directly proportional to its deflection, as defined by Hooke's law. The spring force is determined by the spring rate and the deflection, and it is expressed in units of force, such as Newtons or pounds-force.

The fatigue life of a spring refers to the number of compression cycles it can withstand before failure. Fatigue is caused by repetitive stress, and it can lead to cracks and eventually fracture. Factors such as the spring material, loading conditions, and environmental factors affect the fatigue life.

Selecting the appropriate compression coil spring for a specific application is crucial for optimal performance and longevity. Consider the following factors:

Clearly define the application's specific requirements, such as the required spring force, deflection range, operating environment, and fatigue life.

Choose a spring with a spring rate and deflection range that meet the application's needs. Ensure that the spring's maximum deflection is not exceeded under normal operating conditions.

Select a spring material that can withstand the operating environment and the required fatigue life. Spring steel is a common choice for its strength, resilience, and resistance to fatigue.

Consider the end type of the spring, which determines how it will be attached to the application. Common end types include plain ends, closed ends, and hooked ends.

Compression coil springs are often overlooked, yet they are essential components in countless mechanical systems. Their ability to store and release energy, providing resistance to compression, makes them invaluable in applications ranging from simple door closers to complex industrial machinery. By understanding the principles of compression coil springs, their types, applications, and key performance factors, engineers and designers can ensure the selection and use of these workhorses in their respective fields, leading to optimized system functionality and longevity. The next time you encounter a compression coil spring, remember its unassuming power that makes our modern world function seamlessly.

In conclusion, compression coil springs are remarkable devices that play a vital role in the functionality and reliability of countless mechanical systems. Their simple yet effective design, coupled with their versatility and ability to store and release energy, makes them indispensable across various industries. Understanding their construction, types, applications, and the factors influencing their performance is key to selecting and utilizing these workhorses effectively. As you continue your journey in the world of engineering and design, remember the unassuming power of compression coil springs that contribute to the seamless operation of our modern world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.