Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression coil springs, those ubiquitous helical wonders, are the unsung heroes of countless mechanical systems. From the simple act of opening a door to the intricate workings of automotive suspensions,

Compression coil springs, those ubiquitous helical wonders, are the unsung heroes of countless mechanical systems. From the simple act of opening a door to the intricate workings of automotive suspensions, these springs are constantly at work, storing and releasing energy, providing support, and ensuring smooth operation. But what exactly are compression coil springs, and why are they so essential? Let's delve into the fascinating world of these mechanical marvels.

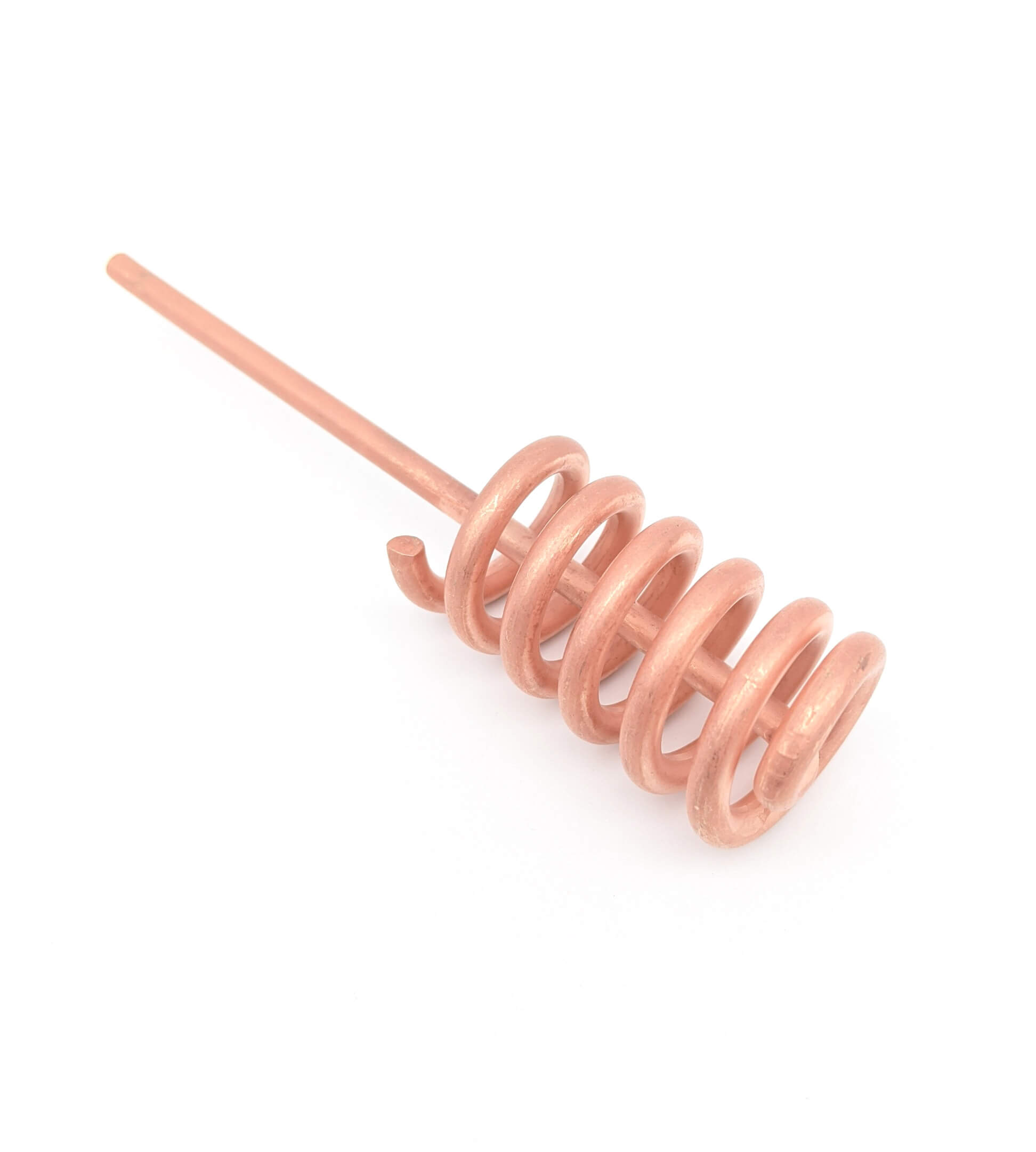

Compression coil springs are a type of spring designed to resist compression forces. They are essentially a coiled wire, usually made of spring steel, that compresses when a force is applied to it. As the spring compresses, it stores potential energy, which is then released when the force is removed, causing the spring to return to its original shape. This ability to store and release energy is the basis for their numerous applications.

The construction of a compression coil spring is surprisingly simple, yet it's precisely this simplicity that allows for a wide range of configurations and functionalities. Key features include:

The versatility of compression coil springs stems from their ability to be tailored to specific applications by modifying their design parameters. For example, changing the wire diameter, coil diameter, or number of coils allows engineers to fine-tune the spring's stiffness, load capacity, and deflection characteristics. This versatility makes them suitable for a wide range of applications, including:

Compression coil springs are indispensable in automotive suspension systems. They provide the primary support for the vehicle, absorbing shocks and vibrations from uneven road surfaces, ensuring a comfortable ride and handling. The springs also help maintain vehicle stability and control.

Compression coil springs are used extensively in various mechanical devices, such as door closers, garage door openers, and machinery components. They are also employed in valves, actuators, and other devices that require controlled movement and force application.

You might be surprised to learn that compression coil springs are ubiquitous in everyday consumer products. They are used in pens, retractable pens, and even some toys. Their compact size and reliability make them ideal for applications where space is limited and consistent performance is crucial.

The behavior of compression coil springs is governed by a fundamental principle in physics known as Hooke's Law. This law states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. In simpler terms, the more you compress a spring, the more force it will exert back.

The spring rate, as mentioned earlier, is a key parameter that dictates the spring's behavior. It is a constant that represents the force required to compress the spring by one unit of length. A higher spring rate means a stiffer spring that requires more force to compress.

The spring rate is a crucial parameter that determines how the spring will behave under load. A higher spring rate translates to a stiffer spring that resists compression more strongly, while a lower spring rate signifies a softer spring that compresses more easily. Understanding the relationship between spring rate and load is essential for designing and selecting springs for specific applications.

For instance, in automotive suspension systems, the spring rate is carefully chosen to provide optimal ride comfort and handling. A stiffer spring will improve handling but can make the ride harsher. Conversely, a softer spring will provide a smoother ride but may compromise handling.

Selecting the right compression coil spring for your application involves considering several factors, including:

Compression coil springs are more than just coiled pieces of wire; they are essential components in countless mechanical systems. Their ability to store and release energy, provide support, and control movement makes them invaluable in applications ranging from automotive suspension to consumer products. Understanding their design, function, and selection criteria empowers engineers and designers to leverage the power of these mechanical marvels to create innovative and reliable solutions.

As you continue to explore the world of mechanics, remember the humble compression coil spring. It's a testament to the power of simple yet ingenious engineering principles, and it's likely to play a critical role in shaping the future of mechanical design. Next time you encounter a door that smoothly closes or a car that handles with precision, take a moment to appreciate the tireless work of these unsung heroes – the compression coil springs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.