Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered about the unseen forces that keep our world moving smoothly? While we might admire towering skyscrapers and sleek vehicles, we often overlook the humble compression coil

Have you ever wondered about the unseen forces that keep our world moving smoothly? While we might admire towering skyscrapers and sleek vehicles, we often overlook the humble compression coil spring. These seemingly simple devices, crafted from coiled metal, are the unsung heroes of modern engineering, silently working to support, dampen, and control countless mechanisms around us. From the smooth suspension of our cars to the precise movements of medical instruments, compression coil springs play a crucial role in our daily lives, ensuring that our world functions efficiently and comfortably.

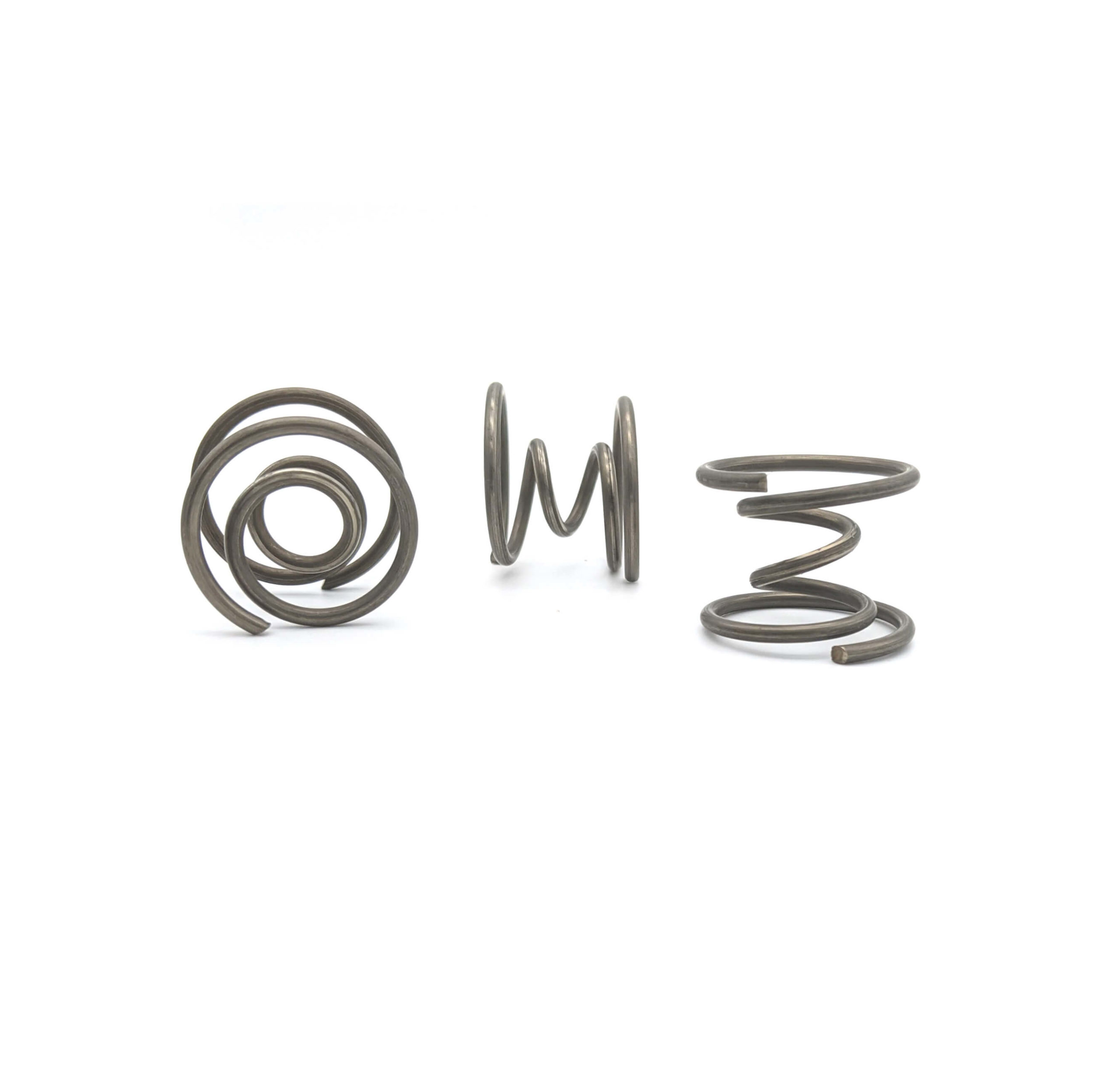

Compression coil springs, also known as helical compression springs, are one of the most common types of springs. They work by storing potential energy when compressed, and releasing that energy to provide a restoring force when the load is removed. These springs are typically made from coiled wire, and their spring rate, or stiffness, is determined by factors such as the wire diameter, the number of coils, the material used, and the spring's free length.

Imagine a Slinky, that classic toy that bounces down the stairs. That's essentially a compression coil spring in action. When you push down on a Slinky, you're compressing the coils, storing energy. Once you let go, the spring releases that stored energy, pushing back upwards. This is the fundamental principle behind compression coil springs.

Compression coil springs find widespread applications in a vast array of industries and everyday objects. Let's explore some examples that highlight their remarkable versatility:

Automotive Industry: Perhaps the most common application of compression coil springs is in vehicle suspension systems. They're essential for providing a comfortable ride by absorbing shocks and bumps on the road. They also help maintain the vehicle's stability and control during driving.

Mechanical Engineering: Compression coil springs are indispensable in various mechanical applications, such as:

Consumer Products: Compression coil springs are also found in numerous everyday objects, such as:

Medical Industry: Compression coil springs are used in various medical devices, such as:

Selecting the appropriate compression coil spring for a specific application involves careful consideration of several factors:

Spring rate: Determines the spring's stiffness, which is crucial for the desired force and displacement. A higher spring rate means a stiffer spring, while a lower spring rate means a more flexible spring.

Free length: Refers to the spring's uncompressed length. This determines the maximum compression distance the spring can handle.

Wire diameter: Affects the spring's strength and durability. A thicker wire diameter results in a stronger spring, while a thinner wire diameter yields a more flexible spring.

Material: The choice of material depends on the specific application requirements. Common materials include steel, stainless steel, and other alloys, each offering varying properties in terms of strength, corrosion resistance, and temperature tolerance.

End type: Refers to the shape of the spring's ends, which can be customized for specific attachment methods and applications. Common end types include closed ends, open ends, and ground ends.

As technology continues to advance, we can expect to see even more innovative applications for compression coil springs. The development of advanced materials, such as composites and shape memory alloys, is opening up new possibilities for creating springs with enhanced properties and functionalities.

Furthermore, the integration of electronics and sensors with compression coil springs is enabling the creation of smart springs, which can monitor their own performance, adapt to changing conditions, and communicate with other systems. This evolution is poised to revolutionize the way we design and use springs in various fields.

Compression coil springs are ubiquitous components that silently contribute to the smooth functioning of our world. They are the unsung heroes of modern engineering, offering resilience, control, and efficiency in countless applications. From the suspension of our cars to the precision of medical instruments, compression coil springs continue to play a vital role in shaping our technological landscape.

As we navigate an increasingly complex world, the simple yet powerful principles of compression coil springs will continue to be essential for ensuring a smooth and efficient future. These seemingly ordinary devices are a testament to the ingenuity and creativity of human engineers, reminding us that even the most fundamental components can have a profound impact on our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.