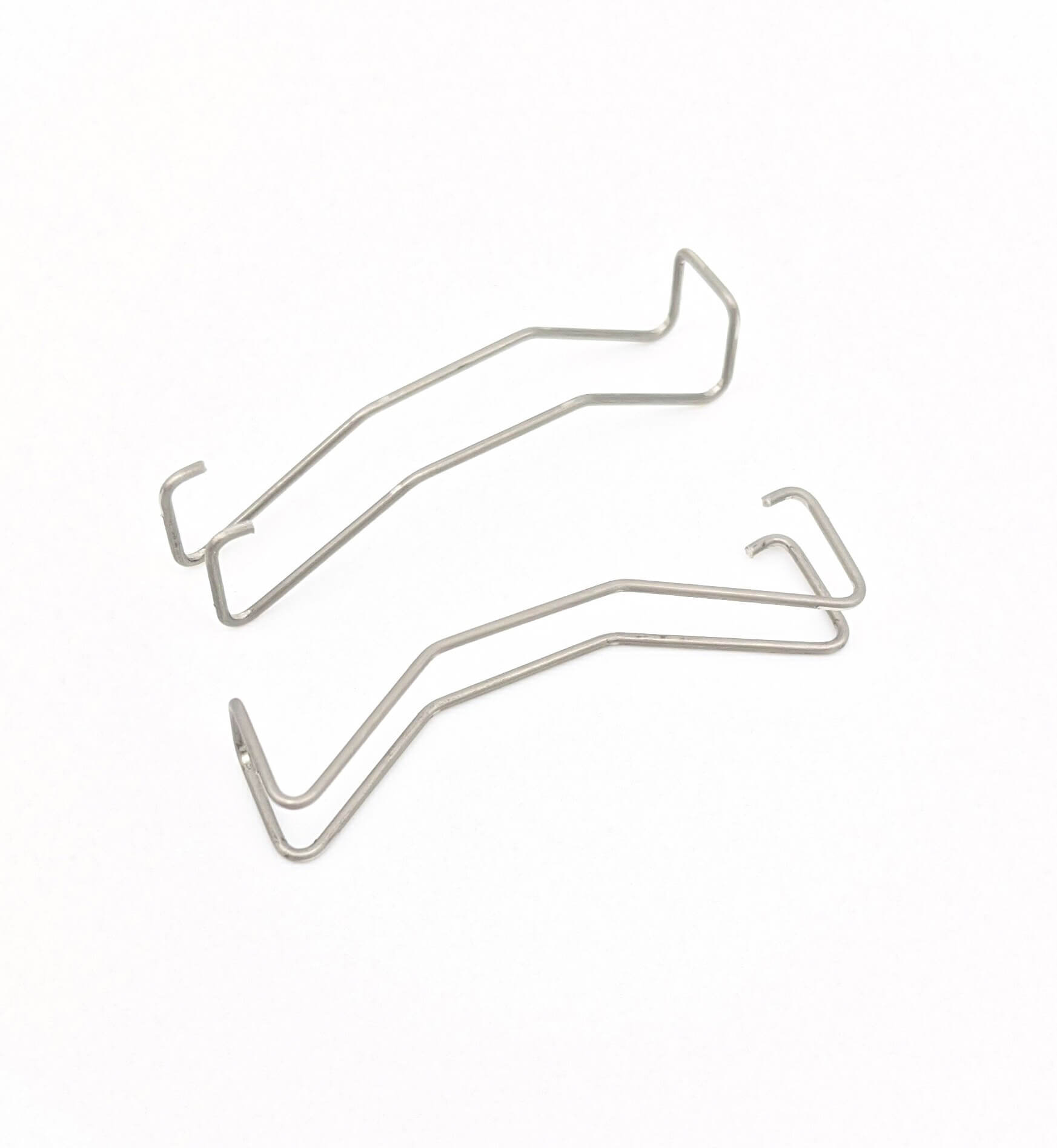

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression coil springs, those ubiquitous metal spirals, are often overlooked, yet they play a crucial role in countless mechanical systems. From the simple act of opening a door to the

Compression coil springs, those ubiquitous metal spirals, are often overlooked, yet they play a crucial role in countless mechanical systems. From the simple act of opening a door to the complex workings of a car's suspension, these seemingly unassuming components contribute significantly to our daily lives. This article delves into the fascinating world of compression coil springs, exploring their design, functionality, and the critical role they play in various industries.

Compression coil springs, as their name suggests, are helical springs designed to absorb and store energy when subjected to a compressive force. They are typically made from high-strength steel wire, carefully coiled into a helical shape. The key to their functionality lies in the spring constant, a measure of how much force is required to compress the spring by a specific distance. This spring constant, often denoted by 'k', is determined by factors such as the material's properties, wire diameter, coil diameter, and the number of coils.

When a force is applied to a compression coil spring, the coils are pushed closer together. The spring resists this compression, storing the applied energy as potential energy within its elastic deformation. Upon release of the force, the spring returns to its original shape, releasing the stored energy. This ability to absorb and release energy makes compression coil springs indispensable for a wide range of applications.

The versatility of compression coil springs shines through in their diverse applications across numerous industries. Here are a few examples that showcase their significance:

Automotive Industry: Compression coil springs are essential components in vehicle suspensions. They provide the necessary cushioning and support to absorb shocks and vibrations, ensuring a smooth and comfortable ride. They also play a vital role in controlling the vehicle's body roll and bounce, enhancing stability and handling.

Industrial Machinery: From heavy-duty presses to intricate assembly lines, compression coil springs are extensively used in industrial machinery. They provide the necessary force for clamping, pressing, and other operations, ensuring smooth and reliable operation. Their ability to store and release energy makes them ideal for power return mechanisms in various industrial applications.

Consumer Products: You might be surprised to learn that compression coil springs are present in numerous everyday items. They are found in door closers, retractable pens, and even toys. These seemingly simple devices rely on the reliable force and energy storage capabilities of compression coil springs to function correctly.

The design of a compression coil spring is crucial to its effectiveness and longevity. Engineers must carefully consider factors such as:

Material Selection: The choice of material is critical. High-strength steel is often favored due to its high elastic limit and fatigue resistance. However, other materials like stainless steel or spring brass may be used depending on the specific application and environmental conditions.

Coil Diameter and Wire Diameter: These dimensions directly impact the spring's stiffness and load capacity. A larger coil diameter will generally lead to a softer spring, while a thicker wire diameter will result in a stiffer spring.

Number of Coils: The number of coils influences the spring's compression travel and load capacity. More coils generally provide greater travel and lower stiffness.

End Design: The ends of the spring can be designed in various ways, such as closed loops, open loops, or ground ends. The end design impacts the spring's ability to transfer forces and its overall stability.

While compression coil springs may appear simple at first glance, they are sophisticated components that play a vital role in countless mechanical systems. Their ability to absorb and release energy, coupled with their versatility and reliability, has made them indispensable across various industries.

Understanding the design, functionality, and applications of compression coil springs is essential for engineers, designers, and anyone working with mechanical systems. These unassuming components deserve recognition for their crucial contributions to our technological world.

The next time you encounter a compression coil spring, take a moment to appreciate its silent but essential role in making our lives easier and more efficient. These simple metal spirals are often overlooked but are truly the unsung heroes of countless mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.