Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

They're often hidden from view, tucked away inside machines and devices, yet compression coil springs play a vital role in countless industries. These humble components provide essential functions like storing

They're often hidden from view, tucked away inside machines and devices, yet compression coil springs play a vital role in countless industries. These humble components provide essential functions like storing and releasing energy, absorbing shocks, and maintaining tension in various applications. This article delves into the world of compression coil springs, exploring their diverse applications, manufacturing processes, and the crucial role they play in modern life.

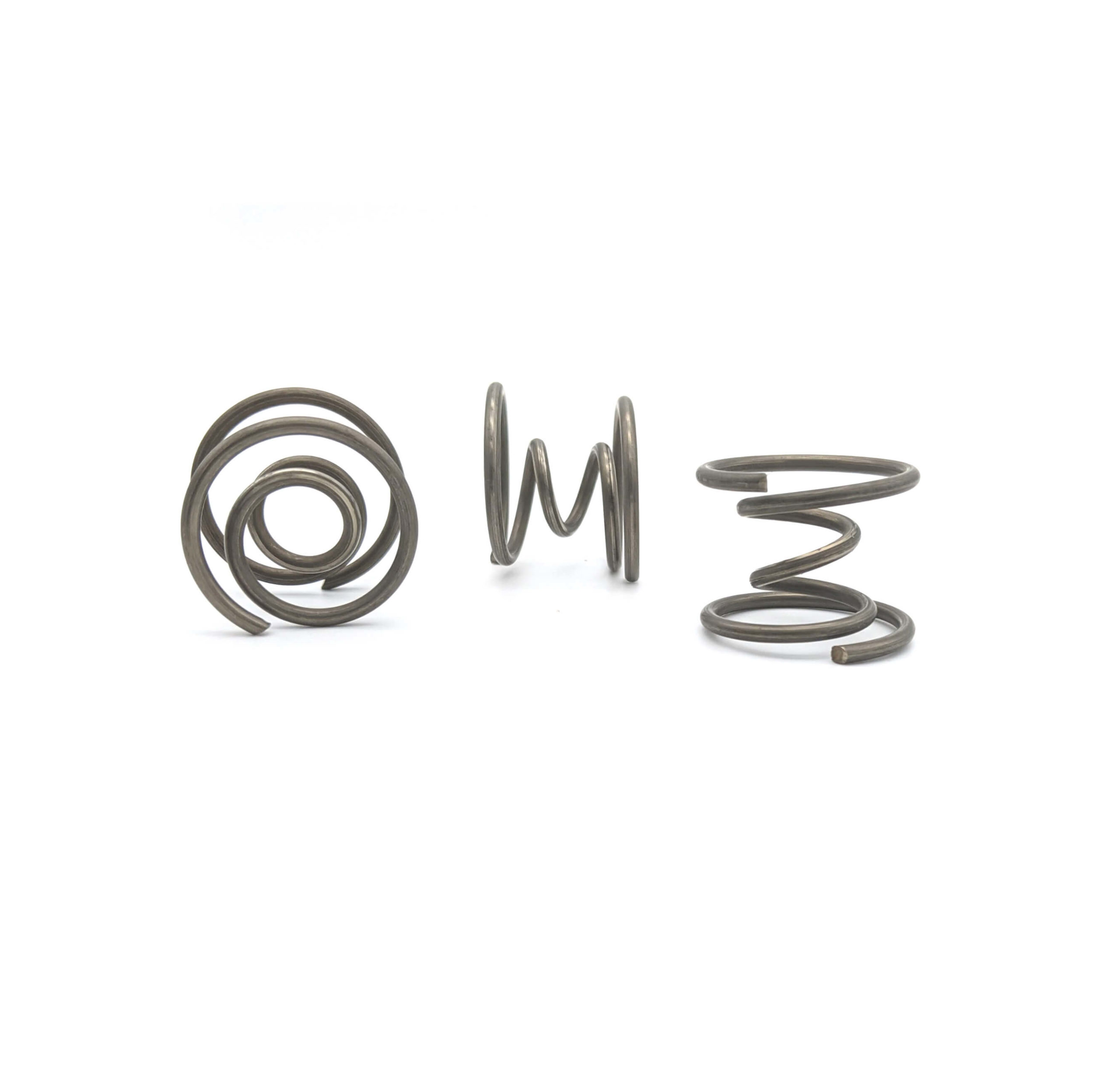

Compression coil springs, as the name suggests, are helical springs designed to absorb and store energy when compressed. Made from a variety of materials, including steel, stainless steel, and even exotic alloys, they are crafted into different shapes and sizes to meet specific needs. The spring's ability to store and release energy, or its 'spring constant,' is determined by factors like the material used, the wire diameter, and the number of coils.

These springs are not just simple metal coils; they are intricate components engineered to withstand specific loads and perform under diverse conditions. Their reliability and durability are paramount, especially in applications where safety is critical. From the smallest of gadgets to massive industrial equipment, compression coil springs are present in a wide array of products, quietly working to ensure smooth and efficient operation.

The versatility of compression coil springs is reflected in their diverse applications across numerous industries. Here are just a few examples:

Automotive Industry: Compression coil springs are essential in car suspensions, absorbing shocks and vibrations from the road, contributing to a comfortable ride and maintaining vehicle stability.

Industrial Machinery: From heavy-duty equipment like forklifts to intricate manufacturing machinery, compression springs are used for everything from clamping and holding components to providing tension in belts and cables.

Consumer Products: They are found in everyday items like pens, toys, and appliances. The spring in a pen retracts the tip when not in use, while a refrigerator door relies on a compression spring to keep the door closed securely.

Aerospace: Even in aerospace applications, compression springs play a critical role, providing reliable operation in extreme environments and demanding conditions.

The manufacturing of compression coil springs is a precise and intricate process that involves several key steps:

1. Material Selection: The choice of material depends on the application's requirements. For instance, steel springs are commonly used for their strength and affordability, while stainless steel offers superior corrosion resistance.

2. Wire Drawing: The raw material, typically wire, is drawn through a series of dies to reduce its diameter and achieve the desired wire gauge. This process imparts specific properties to the wire, such as strength and ductility.

3. Coiling: The wire is then fed into a coil winding machine, where it is wound into a helical shape. The winding process is precisely controlled to ensure the desired number of coils, spring index (ratio of coil diameter to wire diameter), and coil pitch.

4. Heat Treatment: Once coiled, the spring is subjected to heat treatment to enhance its properties, such as hardness, strength, and fatigue resistance. The specific heat treatment process depends on the desired performance characteristics.

5. Finishing: The final step involves cleaning and finishing the spring. This may include shot peening (a process that improves surface finish and increases fatigue resistance) or coating to prevent corrosion.

While compression coil springs might seem simple at first glance, there are numerous factors to consider when selecting the right spring for a specific application. These factors include:

Spring Rate: Also known as the spring constant, this refers to the force required to compress the spring a specific distance. A higher spring rate indicates a stiffer spring, while a lower spring rate means the spring is more compliant.

Free Length: The free length is the uncompressed length of the spring. This is an important parameter for determining the spring's range of motion and overall dimensions.

Solid Height: The solid height refers to the compressed length of the spring when it is fully compressed, with the coils touching each other.

Load Capacity: This refers to the maximum load that the spring can withstand without permanently deforming. The load capacity is directly related to the spring's material properties and design.

Despite their long history, compression coil springs continue to evolve. Technological advancements in material science and manufacturing processes are leading to the development of new alloys with enhanced strength, fatigue resistance, and corrosion resistance. This allows for the creation of springs that can withstand even more demanding conditions and perform more reliably. Furthermore, advancements in design software enable engineers to optimize spring designs for specific applications, resulting in more efficient and cost-effective solutions.

Compression coil springs are a testament to the power of simple yet effective design. They are the silent workhorses that power countless machines, devices, and products, making our lives easier and more efficient. Their ubiquitous presence in modern society underscores their vital role in almost every aspect of our lives. From the car we drive to the toys we play with, these seemingly simple components are the unsung heroes of many industries.

As technology continues to advance, compression coil springs will undoubtedly continue to evolve, finding new applications and pushing the boundaries of what they can achieve. Their story is a reminder that innovation and progress can be found in the most unexpected places, even in the humble compression coil spring.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.