Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

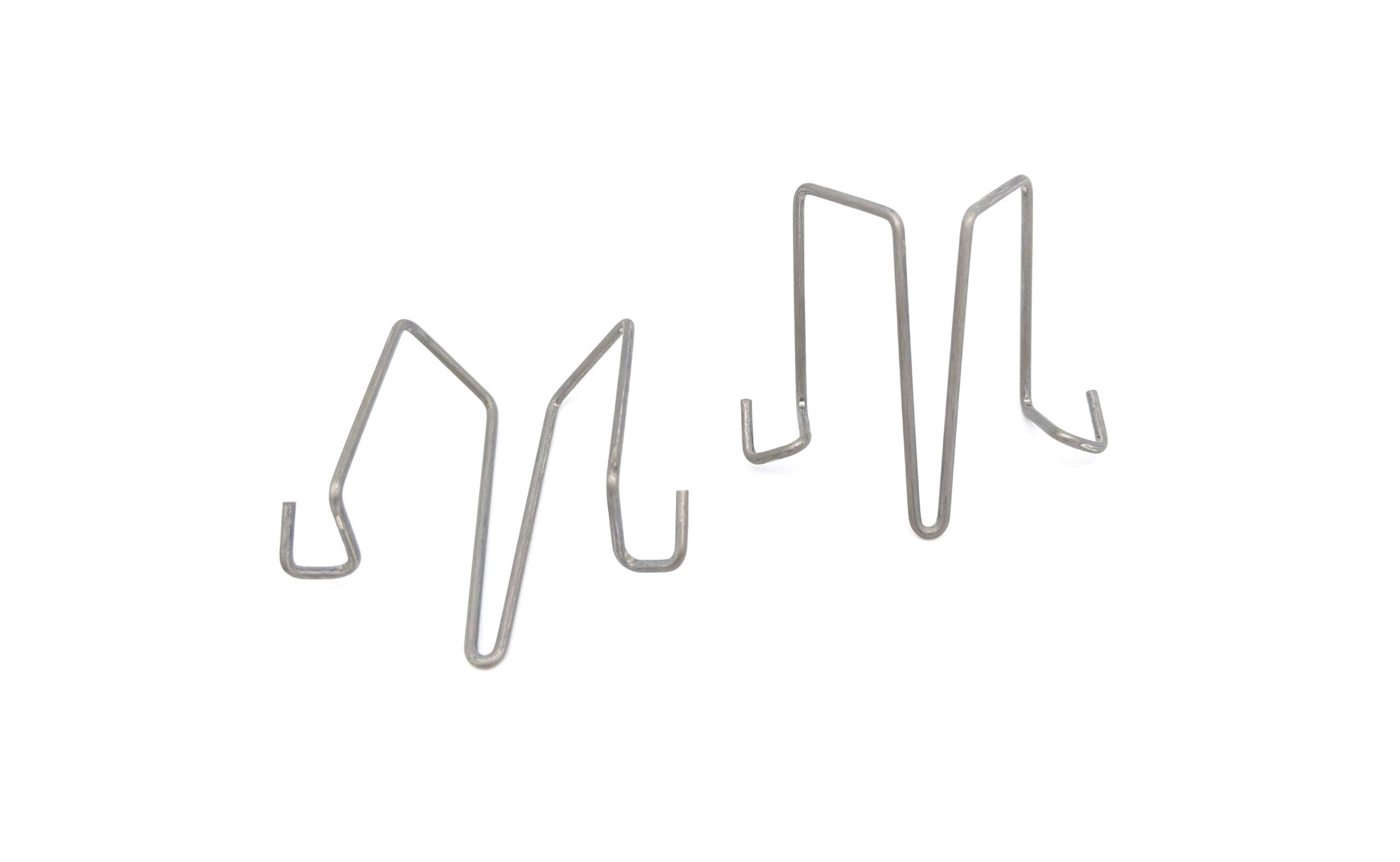

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of engineering and design, the quest for enhanced performance and durability is a constant pursuit. One crucial aspect of achieving this goal lies in the careful selection

In the world of engineering and design, the quest for enhanced performance and durability is a constant pursuit. One crucial aspect of achieving this goal lies in the careful selection and implementation of load-bearing components. Among these, springs play a vital role, providing resilience and shock absorption to various systems. When it comes to struts, a common component in many mechanical structures, the use of compression springs offers distinct advantages that can significantly impact the overall efficacy and longevity of the system. This article delves into the intricacies of compressing springs on struts, exploring their benefits, considerations, and applications.

Compression springs, as the name suggests, are designed to resist compressive forces. When a load is applied, they shorten in length, storing potential energy. This stored energy is then released as the spring returns to its original shape, providing a restoring force. In the context of struts, these springs act as shock absorbers, absorbing and dissipating energy generated by impacts, vibrations, and other external forces.

Struts, on the other hand, are structural elements that provide support and stability to a system. They are often used in suspension systems, aircraft landing gear, and other applications where vertical loads need to be managed. When compression springs are integrated into struts, they create a dynamic system that enhances the strut's performance and lifespan.

The combination of compression springs and struts offers numerous advantages, making it a popular choice in various engineering applications. Some of the key benefits include:

Enhanced Shock Absorption: Compression springs on struts excel at absorbing shock loads, effectively mitigating the impact of sudden forces. This is crucial in preventing damage to the strut itself and other components in the system. Imagine a car driving over a bump: the spring absorbs the impact, preventing the jarring experience that would otherwise occur. This ability to absorb shock is vital in protecting sensitive components from damage and improving the overall ride comfort in vehicles.

Improved Durability: By absorbing shock loads, compression springs reduce the stress on the strut, thereby increasing its lifespan. Instead of the strut bearing the brunt of the impact, the spring absorbs the energy, distributing it over its coils and reducing the strain on the strut. This principle applies not only to vehicles but also to various mechanical systems, ensuring that components last longer and require less frequent maintenance.

Increased Load Capacity: Compression springs effectively increase the load capacity of struts. By taking over a portion of the load, the spring allows the strut to handle greater forces without experiencing excessive strain or deformation. This is particularly beneficial in applications requiring high load bearing capabilities, such as heavy machinery, construction equipment, and even aerospace structures. The ability to manage heavier loads without compromising performance is a significant advantage of incorporating compression springs into strut systems.

Improved Stability: Compression springs can enhance the stability of struts by providing a constant restoring force. As the spring compresses, it resists further compression, maintaining the strut's position and ensuring stability. This is particularly important in systems where stability is paramount, such as aircraft landing gear and suspension systems where maintaining control and preventing unwanted movement is essential.

While compression springs offer numerous advantages when integrated with struts, there are several factors to consider during the design and implementation process. These considerations include:

Spring Rate: The spring rate determines how much force is required to compress the spring by a specific distance. The spring rate is crucial in ensuring the spring operates within its desired range and provides the necessary shock absorption and load capacity. Selecting the right spring rate for the specific application is essential to optimize performance and durability. An overly stiff spring might not provide sufficient shock absorption, while a spring that is too soft might not be able to handle the required load. Careful calculations and analysis are necessary to determine the optimal spring rate for the system.

Spring Material: The material used to manufacture the spring plays a vital role in its performance and lifespan. Spring steel is a common choice due to its high strength and resilience. However, the specific grade of spring steel should be selected based on the operating environment, load requirements, and potential corrosion concerns. Other materials, such as stainless steel or titanium, might be chosen for applications requiring resistance to specific chemicals or extreme temperatures.

Spring Design: The design of the spring itself influences its performance and longevity. Factors such as the number of coils, the coil diameter, and the wire diameter affect the spring's rate, load capacity, and fatigue resistance. Careful consideration should be given to these design parameters to ensure the spring operates within its intended range and meets the application's specific requirements.

Installation and Maintenance: The installation of the spring on the strut must be done carefully to avoid damaging the spring or the strut. Proper alignment and securing methods are crucial to prevent premature wear or failure. Regular inspection and maintenance are also essential to ensure the spring remains in optimal condition and continues to perform as intended.

The combination of compression springs and struts finds extensive applications in various industries, including:

Automotive: Compression springs are widely used in vehicle suspension systems, absorbing shock loads from bumps, potholes, and uneven surfaces. They provide a comfortable ride, enhance handling, and contribute to the overall safety of the vehicle. The springs in suspension systems are often designed with variable spring rates, which can adapt to different driving conditions and loads. They provide a smoother ride when driving over minor bumps and offer better handling when cornering or braking.

Aerospace: In aircraft, compression springs are used in landing gear to absorb the impact of landing. They also help in maintaining stability during takeoff and landing, ensuring a smooth and controlled descent. The springs in landing gear are usually very robust, able to withstand high loads and frequent use. They are also often designed to be shock-resistant and durable to withstand the harsh conditions of takeoff and landing.

Industrial Machinery: Compression springs are essential components in many industrial machines, providing shock absorption and load support. They are used in presses, conveyors, packaging machines, and other heavy-duty equipment, ensuring smooth operation and extended lifespan. These springs are often subjected to high loads and cyclical stresses. They are designed to withstand these harsh conditions and provide reliable performance over a long period.

Consumer Products: Even in consumer products, you'll find compression springs playing a vital role. From furniture legs to door closers, these springs enhance functionality, provide stability, and add comfort to our daily lives. They are often designed for specific applications and may come in different sizes and configurations depending on the product's requirements.

Compressing springs on struts is a powerful combination that offers significant benefits in terms of performance, durability, and overall system efficacy. By carefully considering factors like spring rate, material, design, installation, and maintenance, engineers can leverage the advantages of this dynamic duo to create reliable and long-lasting systems. Whether it's in vehicles, aircraft, industrial machinery, or consumer products, the use of compression springs on struts continues to play a vital role in enhancing engineering design and shaping the world around us.

In conclusion, the integration of compression springs with struts is a testament to the ingenuity of engineering design. It offers a robust and reliable solution to manage shock loads, increase load capacity, enhance stability, and extend the lifespan of various systems. From the smooth ride of a car to the safe landing of an aircraft, the applications of compressing springs on struts are vast and impactful. As technology continues to advance, the role of these components in various industries is likely to become even more prominent, driving further innovation and improving the performance of countless products and systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.