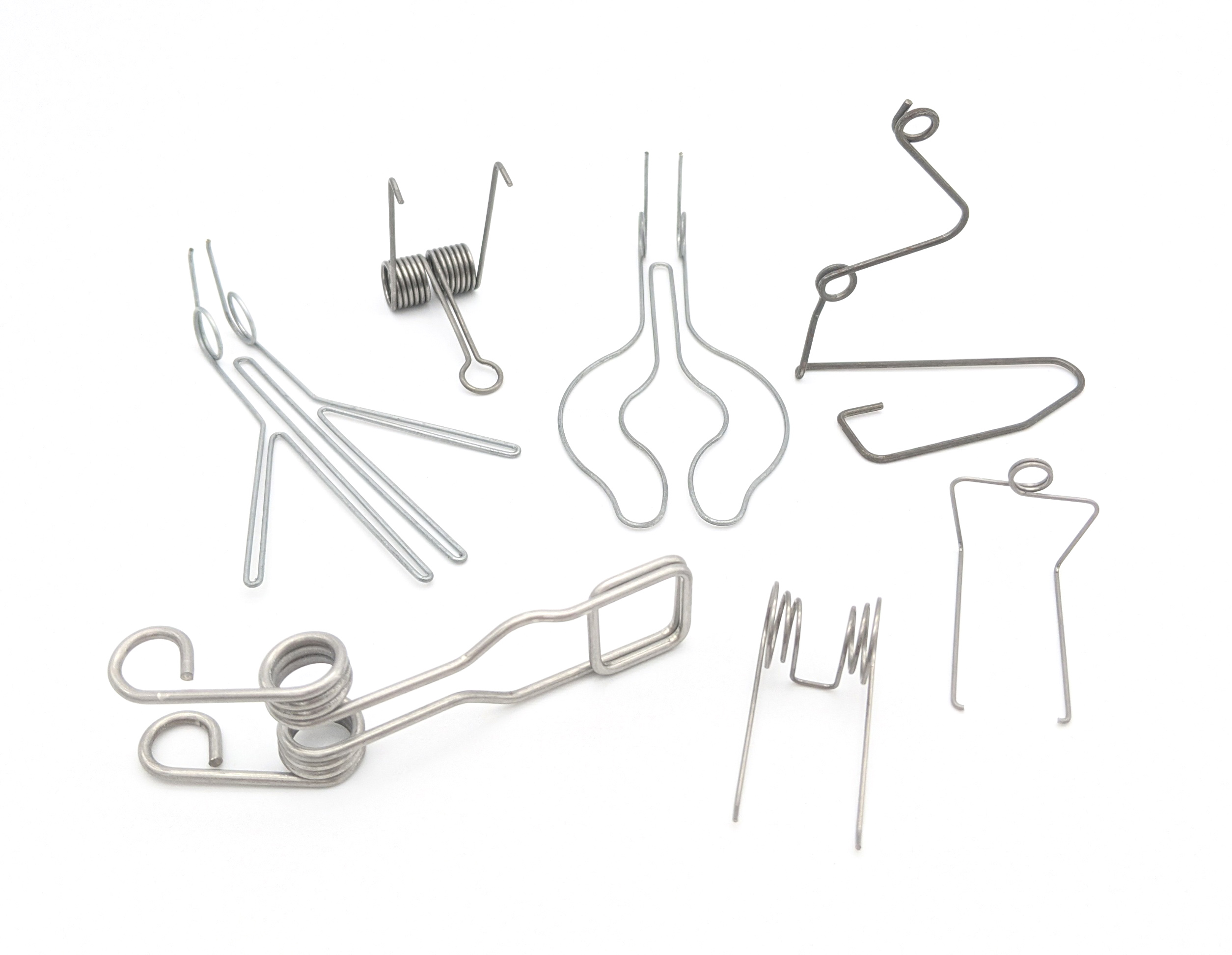

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanics, compressed springs play a vital role. They are deceptively simple devices that embody a powerful principle – the storage of energy. This seemingly innocuous coil

In the world of mechanics, compressed springs play a vital role. They are deceptively simple devices that embody a powerful principle – the storage of energy. This seemingly innocuous coil of metal, when compressed, transforms into a reservoir of potential energy, ready to be unleashed with remarkable force. Whether it's powering a toy car or supporting a heavy structure, the compressed spring's ability to transform stored energy into motion is truly fascinating.

At its core, a compressed spring is a marvel of physics. When you apply force to a spring and compress it, you are essentially storing potential energy within its structure. This energy is not lost, but rather held captive within the spring's tightly wound coils. Imagine it like a coiled-up rubber band—the more you compress it, the more potential energy it holds.

The relationship between the force applied to a spring and the resulting compression is governed by a fundamental principle in physics known as Hooke's Law. This law states that the force required to compress a spring is directly proportional to the amount of compression. In simpler terms, the harder you push on the spring, the more it compresses. This linear relationship is essential for understanding the behavior of springs and designing them for specific applications.

Hooke's Law provides a theoretical framework, but in real-world applications, things can get more complex. Springs can exhibit non-linear behavior, especially when subjected to extreme compression or when they reach their elastic limit. This is where the concept of spring rate comes into play. Spring rate measures how much force is required to compress a spring by a specific distance. It's a crucial factor in designing springs for different applications, ensuring they deliver the desired performance.

Compressed springs find their way into a wide array of applications, from everyday objects to sophisticated machinery. In your car, springs are essential for absorbing shocks and providing a smooth ride. Springs are the driving force behind toys, propelling toy cars and launching projectiles in slingshots. In industrial settings, compressed springs power actuators, clamps, and countless other mechanical systems.

You might be surprised to learn that compressed springs are also found in less obvious places. They are integral components of many household appliances, including refrigerators, washing machines, and ovens. Think about the spring-loaded door on your refrigerator – that's a compressed spring at work! The smooth opening and closing action of these appliances often relies on the controlled release of energy stored in compressed springs.

While compressed springs are incredibly useful, it's crucial to understand their limitations. Every spring has a maximum compression limit—exceed this limit, and the spring could permanently deform or even break. This can lead to malfunctions and safety hazards, especially in applications where springs play a critical role in ensuring safe operation.

The world of spring design is constantly evolving, with innovations in materials, shapes, and manufacturing techniques. New types of springs, such as variable-rate springs and zero-length springs, are being developed to meet the growing demands of modern engineering. These advancements allow designers to create springs that are more efficient, reliable, and adaptable to a wider range of applications.

The seemingly simple act of compressing a spring is a testament to the power of stored energy. From powering toys to safeguarding complex machinery, compressed springs play a vital role in our world. As our understanding of materials and design techniques advances, we can expect to see even more innovative and powerful applications of compressed springs in the years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.