Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil springs, those ubiquitous spirals of metal, are often overlooked, yet they play a vital role in countless aspects of our lives. From the smooth ride in our cars to

Coil springs, those ubiquitous spirals of metal, are often overlooked, yet they play a vital role in countless aspects of our lives. From the smooth ride in our cars to the delicate ticking of our watches, coil springs provide the elasticity and resilience that make our world function. They are silent workhorses, quietly performing their duty, ensuring that things move, stay in place, and return to their original position with ease. This article delves into the fascinating world of coil springs, exploring their history, types, and applications, and highlighting the crucial role they play in our modern world.

The journey of coil springs began long before the industrial revolution. While simple non-coiled springs, like the bow and arrow, have been utilized throughout human history, the invention of coiled springs marked a significant advancement. It was during the 15th century that coiled springs first appeared, making their debut in the intricate mechanisms of door locks. This invention paved the way for the development of spring-powered clocks in the same century, which eventually evolved into the first large watches by the 16th century.

The 17th century saw a groundbreaking discovery that would shape our understanding of springs. In 1676, the brilliant British physicist Robert Hooke formulated Hooke's law, a fundamental principle that governs the behavior of springs. This law states that the force a spring exerts is directly proportional to its extension or compression. This simple yet profound principle laid the foundation for the precise calculations and engineering that underpin the design and use of springs today.

Coil springs are not a one-size-fits-all solution. They come in a multitude of shapes, sizes, and configurations, each tailored to specific applications. Here's a closer look at some of the most common types:

These springs are designed to lengthen under a load. Their coils touch in the unloaded state, and they typically have hooks or loops at each end for attachment. Imagine the spring in a retractable pen – it extends as you pull it, and retracts when released. Tension springs are also found in garage door openers, clotheslines, and many other everyday objects.

In contrast to tension springs, compression springs are designed to shorten when subjected to a load. Their coils are not touching in the unloaded state, and they don't require attachment points. Think of the springs in a car's suspension system – they compress when the car encounters bumps, absorbing the impact and providing a smooth ride. Compression springs also play a key role in door closers, mechanical toys, and many other applications.

This type of spring takes advantage of the internal pressure of a fluid. Hollow tubing is filled with oil, and changing the hydrostatic pressure inside the tubing, through a membrane or piston, allows for controlled hardening or relaxation of the spring. These springs are particularly useful in applications requiring precise and adjustable stiffness, such as hydraulic systems and dampeners.

The applications of coil springs are as diverse as the world itself. They are found in countless products and systems that we rely on daily, making a significant impact on our lives. Here are just a few examples:

Coil springs are essential components of modern vehicles. They are used in the suspension system to absorb shocks and vibrations, ensuring a comfortable and safe ride. Coil springs are also found in braking systems, clutches, and other critical parts of a car. Imagine driving a car with no springs - it would be a bumpy and jarring experience!

From presses to assembly lines, coil springs are indispensable in manufacturing. They are used to provide force for presses, clamps, and other machinery, ensuring accurate and efficient production. Coil springs also play a crucial role in automated systems, ensuring precise movements and controlled actions.

The world of electronics is full of tiny marvels, and coil springs are often hidden within these devices. They are used in switches, connectors, and other components, providing contact pressure and ensuring reliable operation. Think of the spring in a retractable cell phone charger – it provides the tension needed to retract the cord, and the resilience to withstand repeated use.

Coil springs, despite their seemingly simple nature, continue to evolve. Engineers are constantly developing new designs, materials, and manufacturing processes to push the boundaries of their performance. Advanced materials like high-strength alloys and composite materials are being incorporated into springs, improving their durability, strength, and resistance to fatigue. These innovations are leading to lighter, more efficient, and more reliable springs, paving the way for even more exciting applications in the future.

In conclusion, coil springs are more than just simple metal spirals. They are a testament to human ingenuity, a testament to the power of simple yet powerful principles, and a testament to the vital role that engineering plays in our modern world. From the smallest watch to the largest vehicle, coil springs are silently working behind the scenes, ensuring that our world moves smoothly, springs back to life, and remains resilient in the face of challenges.

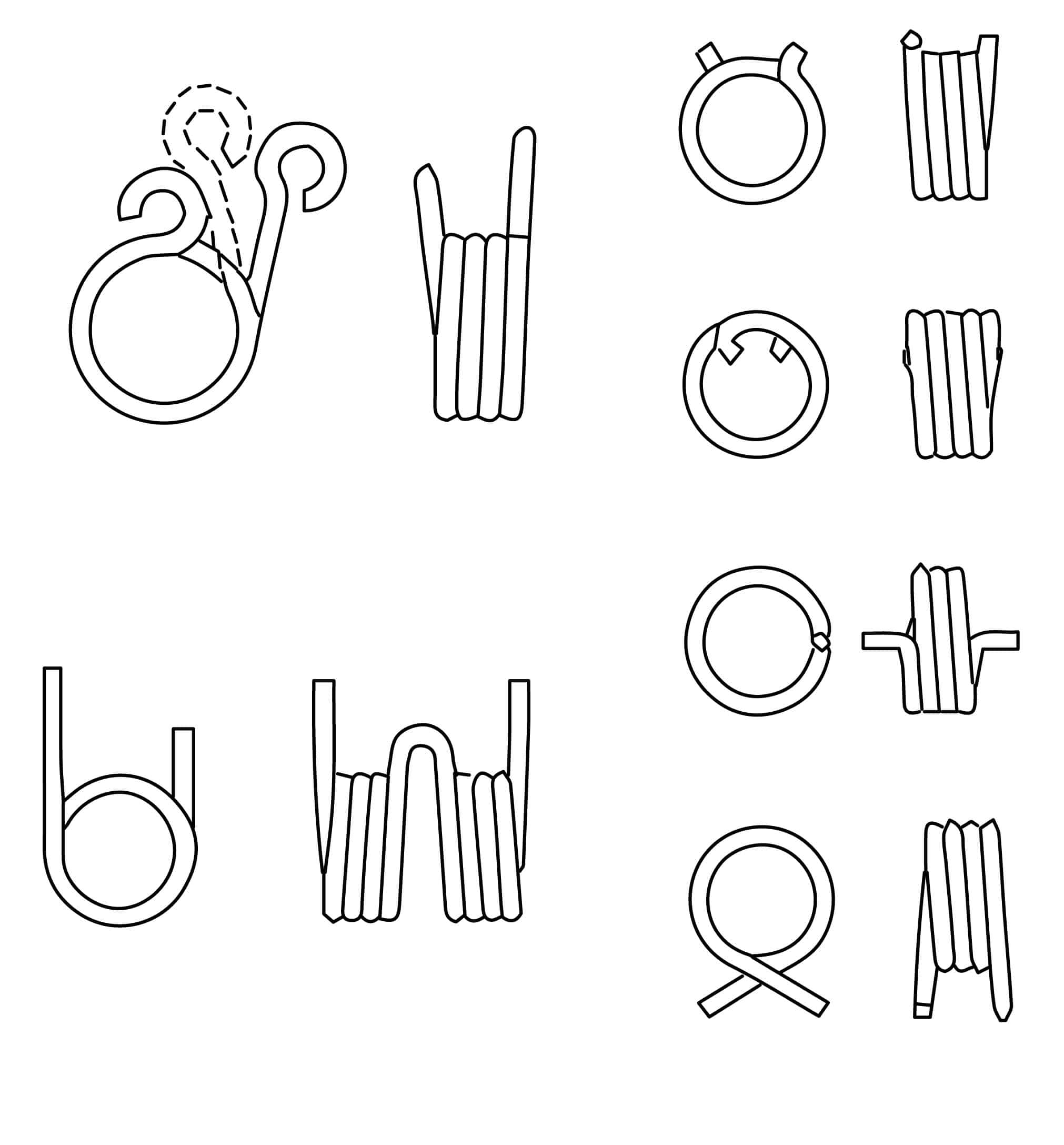

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.