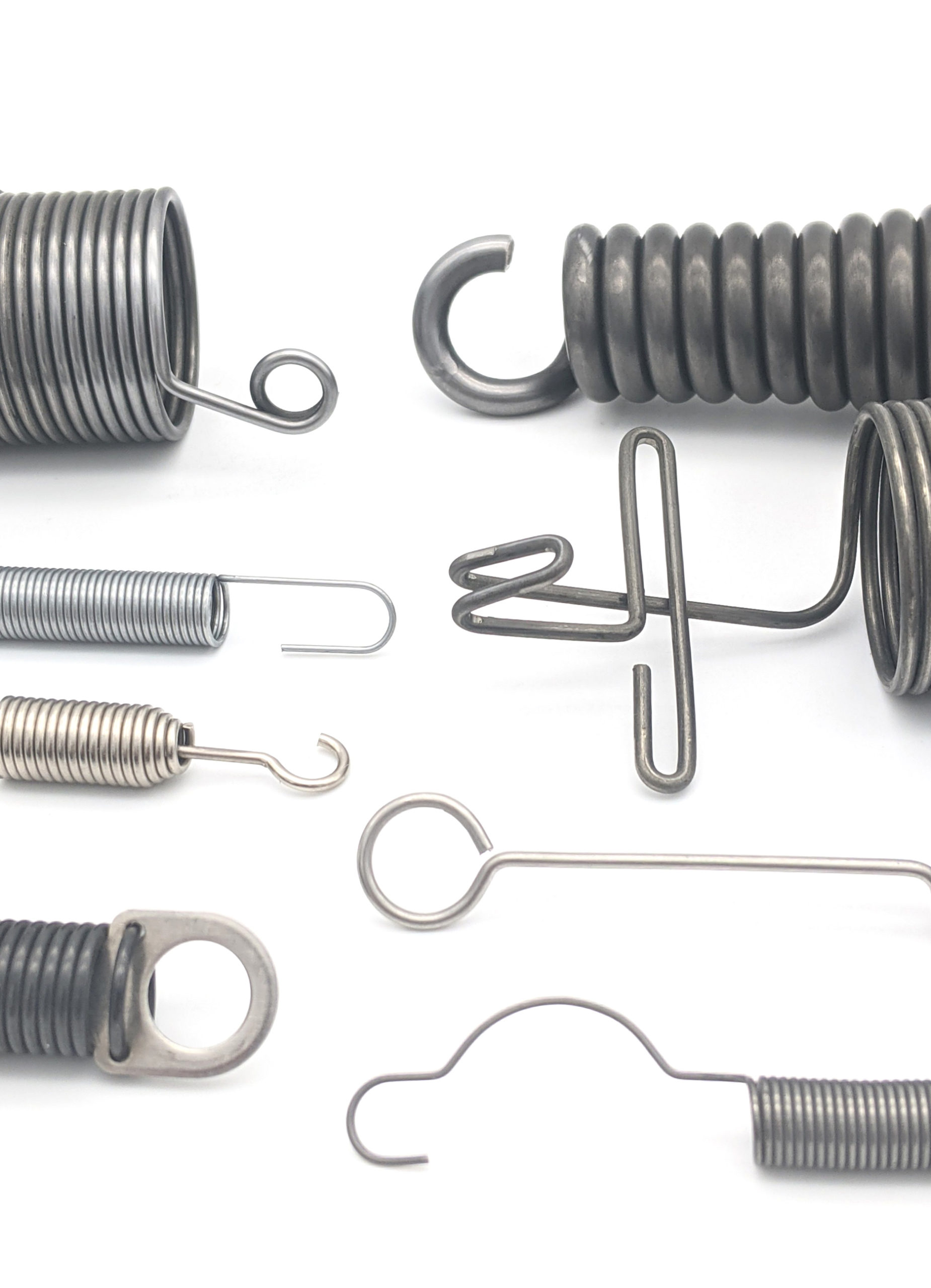

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil springs, those ubiquitous metal spirals found in everything from car suspensions to furniture, are often taken for granted. But these seemingly simple components play a crucial role in our

Coil springs, those ubiquitous metal spirals found in everything from car suspensions to furniture, are often taken for granted. But these seemingly simple components play a crucial role in our daily lives, quietly and efficiently absorbing shocks and vibrations, ensuring smooth motion and stability. From the intricate workings of a car's suspension to the gentle bounce of a mattress, coil springs are the unsung heroes of motion, silently contributing to our comfort and safety.

At their core, coil springs are marvels of physics. They are elastic elements, meaning they can deform under stress and return to their original shape when the stress is removed. This property, known as elasticity, is what makes them so effective at absorbing shocks. When a force is applied to a coil spring, it compresses, storing energy. When the force is removed, the spring expands, releasing the stored energy. This compression and expansion cycle allows the spring to absorb and dissipate energy, preventing it from being transmitted to other components.

The amount of force required to compress a coil spring depends on its material, its diameter, and the number of coils. This relationship is governed by Hooke's Law, which states that the force required to compress or stretch a spring is directly proportional to the distance it is compressed or stretched. This simple yet powerful law forms the basis for understanding and designing coil spring applications.

Coil springs are ubiquitous in our modern world, powering a wide range of applications, both large and small. One of the most familiar uses of coil springs is in car suspensions. These springs, typically made from steel, absorb the bumps and jolts of the road, ensuring a smooth and comfortable ride. They also help to maintain tire contact with the road, improving handling and stability.

Beyond cars, coil springs find applications in a variety of industries. They are used in furniture, providing support and cushioning in sofas, beds, and chairs. They are also essential components in appliances like washing machines, dishwashers, and ovens, helping to dampen vibrations and prevent noise.

In the world of manufacturing, coil springs are vital for precision machinery and equipment. They are used in presses, punches, and other tools to exert controlled forces and ensure accurate operation. They are also employed in robotics and automation, providing the necessary flexibility and resilience for tasks ranging from assembly line operations to delicate surgical procedures.

Coil springs are not a recent invention. Their history dates back centuries, with early forms being used in primitive catapults and other mechanical devices. Over time, the design and manufacturing of coil springs have evolved, with advancements in materials, manufacturing processes, and design techniques. The development of high-strength steels and advanced heat treatments has significantly enhanced the performance and durability of coil springs, allowing them to withstand greater loads and operate under more demanding conditions.

Modern coil springs are now manufactured using sophisticated computer-aided design (CAD) and computer-aided manufacturing (CAM) techniques, enabling highly accurate and efficient production. These advancements have also made it possible to create specialized coil springs for specific applications, with custom designs tailored to meet unique requirements.

Despite their long history and widespread use, coil springs are not a stagnant technology. Ongoing research and development efforts are constantly pushing the boundaries of what's possible with these versatile components. New materials, like composites and shape memory alloys, are being explored to create springs with enhanced properties like lighter weight, higher strength, and greater resilience. The development of advanced manufacturing techniques, such as 3D printing, is also opening up new possibilities for custom-designed and highly efficient coil springs.

The future of coil springs is bright, as they continue to play a vital role in a wide range of applications, from everyday objects to cutting-edge technologies. Their ability to absorb energy and provide support, combined with their adaptability and resilience, makes them essential components for ensuring smooth and stable motion in our modern world.

From the suspension of our cars to the cushioning of our furniture, coil springs are the silent workhorses that keep our world moving. Their simple yet elegant design and remarkable properties make them indispensable components in a vast array of applications. As technology continues to evolve, so too will coil springs, adapting and innovating to meet the challenges of the future. So the next time you encounter a coil spring, take a moment to appreciate its humble yet crucial role in our modern world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.